Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spreading Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

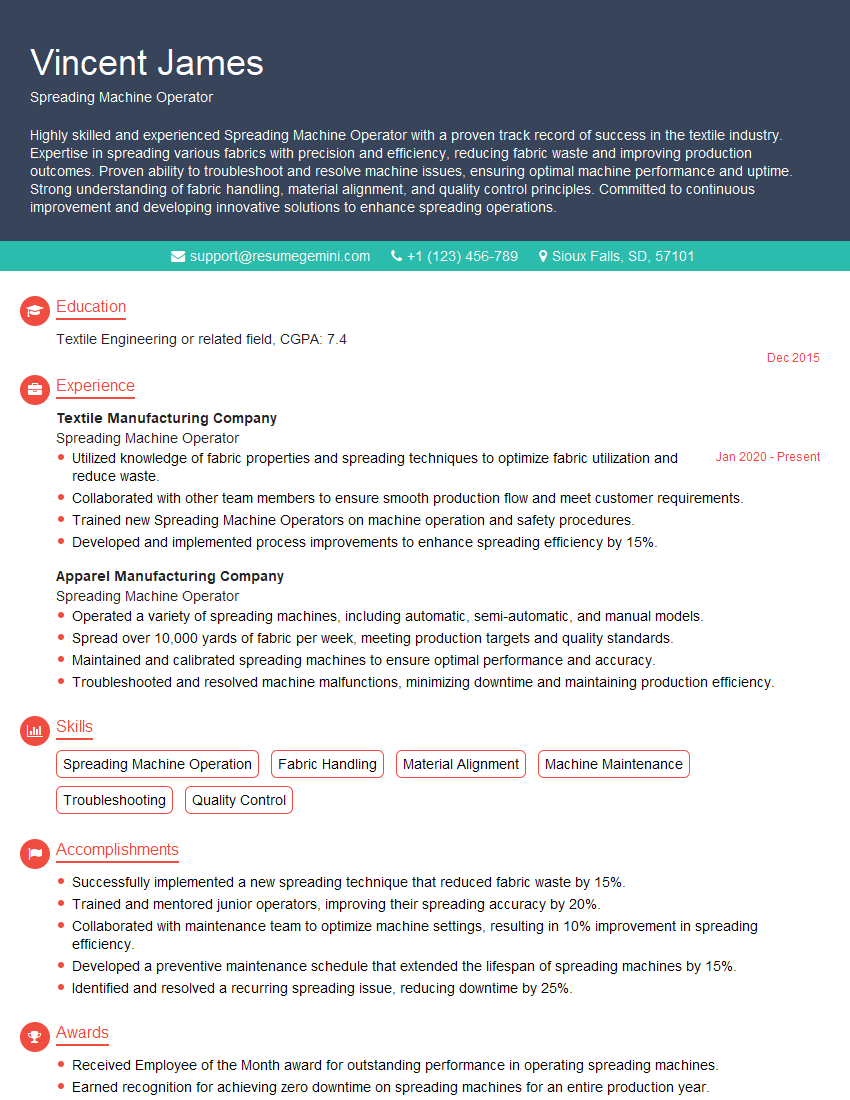

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spreading Machine Operator

1. Describe the key responsibilities of a Spreading Machine Operator?

As a Spreading Machine Operator, my responsibilities encompass a diverse range of tasks, including:

- Setting up and operating spreading machines to spread fabric layers accurately and efficiently.

- Ensuring proper fabric alignment, tension, and spreading width to meet production specifications.

2. Explain the process of calibrating a spreading machine?

Preparing the Machine

- Clean and inspect the spreading machine to ensure it is in good working condition.

- Load the fabric roll onto the fabric creel and thread it through the machine.

Calibration Process

- Set the desired spreading width and tension using the control panel.

- Spread a test piece of fabric and measure the accuracy of the spread.

- Adjust the machine settings as needed to achieve the desired results.

3. How do you troubleshoot common spreading machine problems?

- Fabric wrinkles or puckering: Check fabric tension, spreading width, and machine alignment.

- Uneven spreading: Adjust spreading roller pressure, check fabric alignment, and ensure the fabric is properly loaded.

- Machine jams: Stop the machine immediately, clear any fabric obstructions, and check for mechanical issues.

4. What safety protocols must be followed when operating a spreading machine?

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Keep the work area clean and free of tripping hazards.

- Never reach into the machine while it is running.

5. Describe your experience in managing and maintaining spreading machines?

Throughout my career, I have been responsible for the maintenance and upkeep of several spreading machines. My duties included:

- Performing daily inspections and cleaning to ensure optimal performance.

- Identifying and resolving minor mechanical issues.

- Coordinating with maintenance personnel for major repairs and overhauls.

6. How do you minimize fabric waste and optimize fabric utilization?

- Plan fabric layouts efficiently to maximize fabric usage.

- Use nesting software to minimize fabric waste during cutting.

- Monitor fabric consumption and identify areas for improvement.

7. Explain the importance of fabric tension in the spreading process?

Fabric tension is crucial in the spreading process as it:

- Ensures accurate and consistent spreading.

- Prevents fabric wrinkles or distortion.

- Facilitates smooth and efficient sewing operations.

8. What are the different types of spreading machines and their applications?

- Single-layer spreading machines: Used for spreading a single layer of fabric.

- Multi-layer spreading machines: Capable of spreading multiple layers of fabric simultaneously.

- CNC spreading machines: Computer-controlled machines that offer high precision and automation.

9. How do you stay up-to-date with the latest advancements in spreading technology?

- Attend industry trade shows and conferences.

- Read technical articles and journals.

- Seek training from equipment manufacturers.

10. Why are you interested in working as a Spreading Machine Operator for our company?

I am eager to join your esteemed organization as a Spreading Machine Operator for several reasons:

- Your reputation as a leader in the apparel industry.

- The opportunity to contribute to your company’s success.

- The chance to work with advanced spreading equipment and technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spreading Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spreading Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Spreading Machine Operator is responsible for operating and maintaining spreading machines used in the textile industry to spread fabric layers evenly and accurately. Their primary duties include:

1. Machine Operation

Loading and feeding fabric rolls onto the spreading machine, ensuring correct tension and alignment.

- Adjusting machine settings such as spreading width, fabric tension, and spreading speed to meet production requirements.

- Monitoring the spreading process to ensure fabric layers are spread evenly and free of defects, making adjustments as needed.

2. Machine Maintenance

Conducting routine maintenance and cleaning of the spreading machine, including lubricating moving parts, cleaning sensors, and replacing worn components.

- Identifying and troubleshooting machine malfunctions and taking corrective actions, ensuring efficient operation.

- Performing preventative maintenance tasks as per manufacturer’s guidelines to minimize downtime and extend machine lifespan.

3. Quality Control

Inspecting spread fabric layers for defects such as wrinkles, stains, or misalignments.

- Maintaining accurate records of production and identifying areas for improvement in spreading efficiency.

- Working closely with fabric inspectors to ensure the quality of spread fabric meets customer specifications.

4. Safety and Compliance

Adhering to established safety protocols and industry regulations related to machine operation and fabric handling.

- Wearing appropriate personal protective equipment and maintaining a clean and organized work area.

- Reporting any safety hazards or concerns promptly to ensure a safe work environment for all.

Interview Tips

To ace an interview for a Spreading Machine Operator position, it’s essential to prepare thoroughly. Here are some key tips to help you succeed:

1. Research the Company and Role

Learn about the company’s history, values, and products. Familiarize yourself with the specific requirements of the Spreading Machine Operator role and how it aligns with your skills and experience.

- Visit the company website, read industry news, and consult with professionals in the field to gain insights.

- Identify any unique aspects of the company’s spreading process or the specific machinery used.

2. Highlight Your Relevant Skills and Experience

Emphasize your proficiency in operating and maintaining spreading machines. Provide specific examples of your ability to spread fabric layers evenly, troubleshoot machine issues, and maintain a safe work environment.

- Quantify your accomplishments with metrics, such as the number of fabric layers spread per hour or the reduction in machine downtime achieved.

- Discuss any certifications or training programs you have completed related to spreading machine operation or textile manufacturing.

3. Demonstrate Attention to Detail and Quality

Convey your commitment to accuracy and quality in your work. Highlight your ability to inspect spread fabric layers for defects and maintain high standards of production.

- Share examples of how you have implemented quality control measures or identified areas for improvement in spreading efficiency.

- Explain how your attention to detail ensures that only high-quality fabrics are used in production.

4. Emphasize Safety and Compliance

Stress your understanding of safety protocols and industry regulations related to spreading machine operation and fabric handling. Demonstrate your commitment to maintaining a safe work environment for yourself and others.

- Provide examples of how you have followed safety procedures and identified potential hazards in previous roles.

- Explain how your adherence to compliance requirements ensures the quality and safety of the final products.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spreading Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!