Feeling lost in a sea of interview questions? Landed that dream interview for Spring Coiler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Spring Coiler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

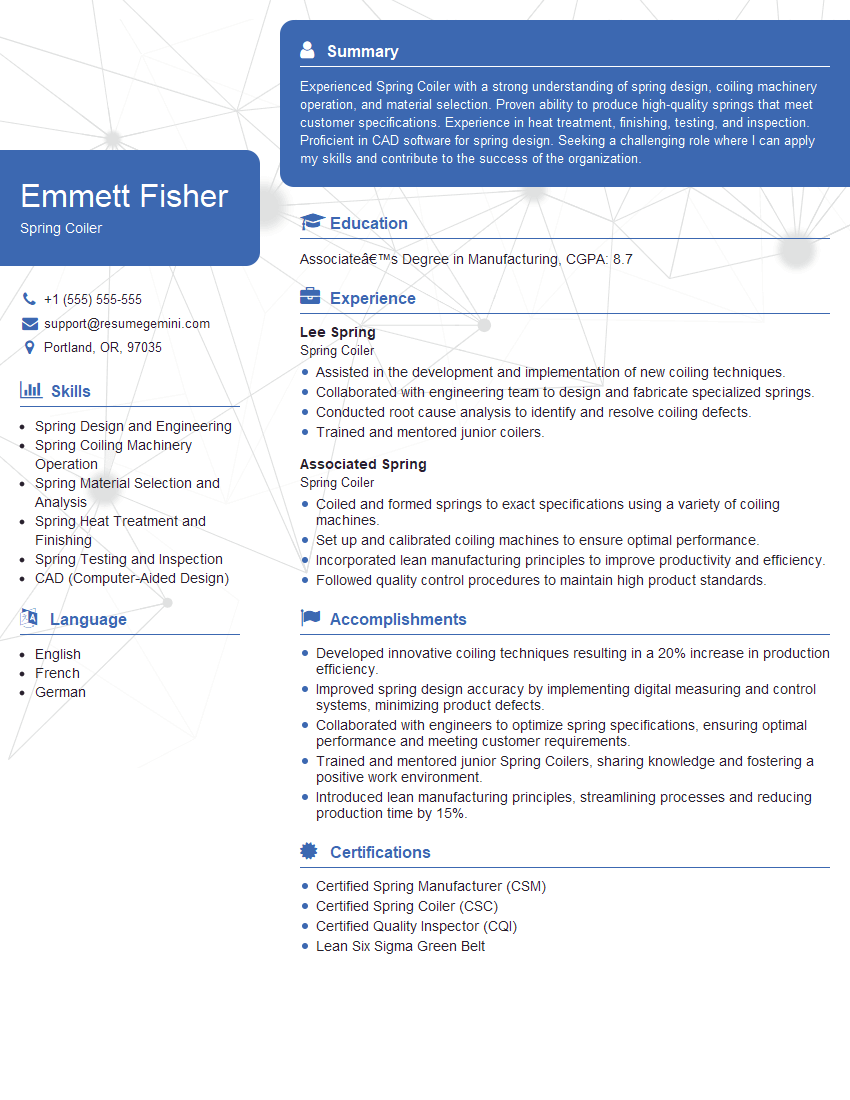

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spring Coiler

1. Describe the process of coiling a spring?

Sample Answer

- Material Preparation: Determine the type and thickness of wire required, and cut it to the desired length.

- Machine Setup: Set up the coiling machine with the appropriate tooling and parameters based on the spring’s specifications.

- Coiling: Feed the wire into the machine, and tension it to prevent buckling. Guide the wire through the forming dies to create the desired shape and coils.

- Heat Treatment (Optional): Some springs require post-coiling heat treatment to improve their mechanical properties and stability.

- Inspection and Testing: Inspect the spring visually and dimensionally, and conduct appropriate tests to ensure it meets the required specifications.

2. What are the different types of spring coiling machines and their applications?

Sample Answer

Types of Spring Coiling Machines:

- CNC Coiling Machines: Computer-controlled machines that offer precision and repeatability for complex spring designs.

- Mechanical Coiling Machines: Manually operated machines for simple spring designs and low-volume production.

- Torsion Coiling Machines: Specialized machines for coiling torsion springs with precise control over the pitch and spacing.

Applications:

- Automotive (suspensions, brakes)

- Electronics (connectors, switches)

- Aerospace (landing gear, actuators)

- Medical equipment (implants, stents)

3. Explain the factors that affect spring design and performance.

Sample Answer

- Material Properties: Tensile strength, yield strength, and modulus of elasticity.

- Spring Dimensions: Wire diameter, coil diameter, and number of coils.

- Loading Conditions: Static load, dynamic load, and fatigue life.

- Environmental Factors: Temperature, corrosion, and vibration resistance.

- Manufacturing Tolerances: Precision of the coiling process and dimensional accuracy.

4. What are the common defects in coiled springs and how can they be prevented?

Sample Answer

Common Defects:

- Buckling: Wire buckling during coiling due to insufficient tension.

- Overlap: Coils overlapping due to incorrect pitch or wire thickness.

- Open Coils: Gaps between coils due to improper tooling or material deformation.

- Conicity: Spring axis not being parallel to the base due to machine misalignment or material variation.

Prevention:

- Ensure proper coiling tension and machine calibration.

- Select appropriate tooling and spring design based on material properties.

- Implement rigorous quality control measures during coiling and inspection.

5. Describe the testing methods used to evaluate spring performance.

Sample Answer

- Tensile Testing: Measures the spring’s tensile strength and yield strength.

- Compression Testing: Determines the spring’s load-deflection characteristics.

- Fatigue Testing: Evaluates the spring’s ability to withstand repeated loading and unloading cycles.

- Corrosion Testing: Assesses the spring’s resistance to environmental degradation.

- Torsion Testing: Tests the spring’s resistance to twisting forces.

6. How do you maintain and troubleshoot spring coiling machines?

Sample Answer

Maintenance:

- Regular lubrication and cleaning of machine components.

- Calibration of sensors and tooling to ensure accuracy.

- Preventative maintenance checks to identify potential issues.

Troubleshooting:

- Diagnose error codes and perform necessary repairs.

- Identify and adjust machine settings to resolve coiling defects.

- Resolve mechanical issues such as jamming, slipping, or noise.

7. What are the safety precautions to observe when operating spring coiling machines?

Sample Answer

- Wear appropriate safety clothing (e.g., gloves, safety glasses).

- Securely tie back long hair or loose clothing to prevent entanglement.

- Follow proper machine operating procedures and lockout/tagout protocols.

- Maintain a clean and organized work area.

- Be aware of potential hazards such as sharp edges, moving parts, and hot surfaces.

8. Explain how you would optimize the coiling process for a specific spring design.

Sample Answer

- Analyze the spring design requirements and determine the optimal wire diameter and coil dimensions.

- Select the appropriate coiling machine and tooling based on the spring’s characteristics.

- Optimize the coiling parameters (e.g., pitch, tension, speed) through experimentation or simulation.

- Conduct rigorous quality control checks to ensure consistent spring production.

- Implement continuous improvement measures to enhance efficiency and reduce defects.

9. Describe your experience in working with different types of spring materials.

Sample Answer

- Carbon Steel: High strength and durability, commonly used for industrial springs.

- Stainless Steel: Corrosion-resistant, suitable for applications in harsh environments.

- Music Wire: High tensile strength and fatigue resistance, used for precision springs.

- Nickel-Titanium Alloys: Shape memory capabilities, used in medical and aerospace applications.

- Non-Metallic Materials: Plastics and composites, for lightweight and non-magnetic springs.

10. How do you stay up-to-date on the latest advancements in spring coiling technology?

Sample Answer

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Network with peers and experts in the field.

- Engage in continuous learning and explore new technologies.

- Collaborate with manufacturers and suppliers to stay informed of product developments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spring Coiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spring Coiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spring Coilers are responsible for setting up, operating, and maintaining machinery that coils wire springs. They also conduct quality control inspections to ensure that the springs meet specifications.

1. Setup and Operation

Spring Coilers set up and operate coil winding machines to produce wire springs according to specifications. They may also operate other related equipment, such as heat treat ovens or grinders.

- Set up coil winding machines according to specifications.

- Load wire onto the machine and adjust the tension.

- Start the machine and monitor its operation.

- Make adjustments to the machine as needed to ensure that the springs meet specifications.

2. Quality Control

Spring Coilers conduct quality control inspections to ensure that the springs meet specifications. They may use a variety of measuring tools to check the springs for dimensions, hardness, and other properties.

- Inspect springs for dimensions, hardness, and other properties.

- Identify and correct any defects.

- Maintain quality control records.

3. Maintenance

Spring Coilers perform routine maintenance on coil winding machines and other related equipment. They may also troubleshoot and repair problems as they arise.

- Perform routine maintenance on coil winding machines.

- Inspect and clean machines regularly.

- Troubleshoot and repair problems as they arise.

4. Safety

Spring Coilers must follow safety procedures to avoid injury. They may also be required to wear personal protective equipment, such as gloves, safety glasses, and earplugs.

- Follow safety procedures to avoid injury.

- Wear personal protective equipment when necessary.

- Maintain a clean and organized work area.

Interview Tips

Preparing for an interview can be stressful, but by following these tips, you can increase your chances of success.

1. Research the Company

Before you go to the interview, take some time to research the company. This will help you understand the company’s culture, values, and products or services. You can find this information on the company’s website, LinkedIn page, and other online sources.

- Visit the company’s website.

- Read the company’s LinkedIn page.

- Search for news articles about the company.

2. Practice Your Answers

Once you have researched the company, start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview. You can practice with a friend, family member, or career counselor.

- Prepare answers to common interview questions.

- Practice your answers out loud.

- Get feedback from a friend, family member, or career counselor.

3. Be Yourself

It’s important to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be confident in your abilities and let your personality shine through.

- Be yourself and let your personality shine through.

- Don’t try to be someone you’re not.

- Be confident in your abilities.

4. Follow Up

After the interview, be sure to follow up with the interviewer. This shows that you’re interested in the position and that you appreciate their time. You can send a thank-you note or email, or you can call the interviewer to follow up.

- Send a thank-you note or email.

- Call the interviewer to follow up.

- Follow up to show your interest in the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Spring Coiler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Spring Coiler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.