Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spring Production Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

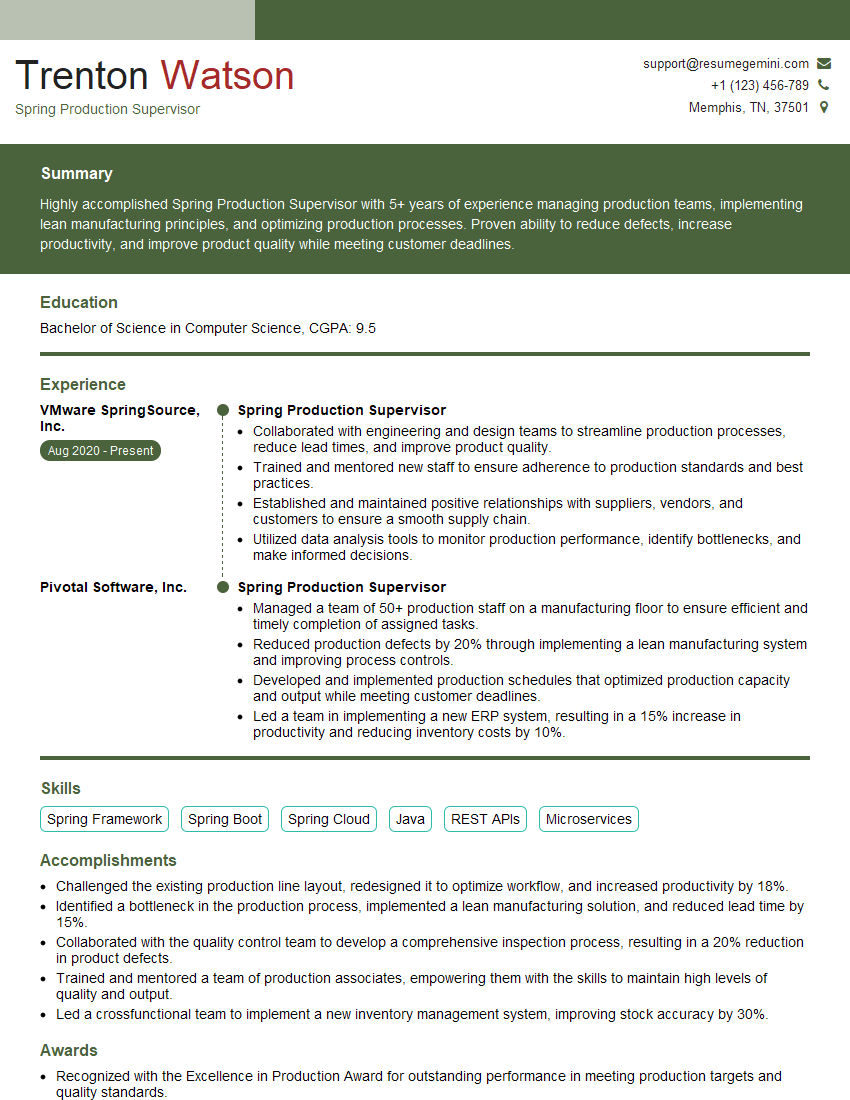

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spring Production Supervisor

1. How do you ensure that the production process is efficient and meets quality standards?

To ensure production efficiency and quality, I follow a comprehensive approach that involves:

- Continuous Improvement: Implementing lean manufacturing principles, such as Kanban and Kaizen, to streamline processes, reduce waste, and improve efficiency.

- Quality Control: Establishing and enforcing strict quality control measures throughout the production process, including inspections, testing, and documentation, to ensure products meet specifications.

- Employee Training: Providing comprehensive training to employees on production processes, quality standards, and safety protocols to ensure they have the necessary knowledge and skills to perform their tasks effectively.

2. Describe your experience in managing a team of production operators. How do you motivate and develop your team?

Team Management:

- Clear Communication: Establishing clear communication channels and fostering open dialogue to ensure everyone is informed, understood, and engaged.

- Goal Setting: Setting realistic and challenging production goals and ensuring team members understand their roles and responsibilities in achieving them.

- Performance Monitoring: Regularly monitoring team performance, providing feedback, identifying areas for improvement, and recognizing achievements.

Team Development:

- Training and Development: Providing opportunities for professional development through training, workshops, and on-the-job coaching to enhance employee skills and knowledge.

- Empowerment: Empowering team members to make decisions, take ownership of their tasks, and contribute to problem-solving.

- Team Building: Fostering a positive and collaborative work environment through team-building activities and regular social interactions.

3. How do you handle production delays and unexpected events?

To handle production delays and unexpected events effectively, I follow a proactive and strategic approach that involves:

- Risk Assessment: Identifying potential risks and developing contingency plans to mitigate disruptions.

- Communication: Promptly informing stakeholders, including customers, about potential delays and providing regular updates.

- Problem Solving: Analyzing the cause of the delay, exploring alternative solutions, and implementing the most effective course of action.

- Resource Management: Allocating resources efficiently, such as overtime or additional equipment, to minimize the impact of delays.

- Continuous Improvement: Learning from the experience of delays and implementing measures to prevent similar occurrences in the future.

4. How do you manage production costs and optimize resource allocation?

To manage production costs and optimize resource allocation, I employ the following strategies:

- Budgeting and Forecasting: Accurately forecasting production costs and developing realistic budgets to control expenses.

- Negotiation: Negotiating with suppliers to secure favorable pricing on materials and services while ensuring quality.

- Inventory Management: Implementing efficient inventory control systems to minimize waste, reduce carrying costs, and optimize stock levels.

- Maintenance and Repairs: Conducting regular maintenance and preventive repairs on equipment to reduce downtime and increase productivity.

- Continuous Improvement: Regularly reviewing production processes and identifying areas for cost reduction and resource optimization.

5. How do you ensure compliance with industry regulations and safety standards?

To ensure compliance with industry regulations and safety standards, I follow a comprehensive approach that involves:

- Regulatory Awareness: Staying up-to-date on relevant industry regulations, standards, and best practices.

- Compliance Audits: Conducting regular internal audits to assess compliance, identify gaps, and implement corrective actions.

- Employee Training: Providing comprehensive training on safety protocols, proper handling of materials, and emergency procedures.

- Equipment Maintenance: Ensuring that production equipment is regularly inspected, maintained, and certified to meet safety standards.

- Incident Reporting and Management: Establishing a robust system for reporting and investigating safety incidents and implementing measures to prevent their recurrence.

6. Describe your experience in implementing new technologies or processes to improve production efficiency.

I am proficient in implementing new technologies and processes to improve production efficiency. Here’s an example:

- Lean Manufacturing Implementation: Led a team in implementing lean manufacturing principles, such as Kanban and Kaizen, which resulted in a 15% reduction in production lead times and a 10% increase in output.

- Automated Quality Inspection: Introduced automated quality inspection systems to reduce human error and improve the accuracy and consistency of product testing, leading to a 5% reduction in product defects.

- Data Analytics for Process Optimization: Utilized data analytics tools to identify production bottlenecks and optimize production schedules, resulting in a 12% increase in overall production capacity.

7. How do you measure and track production performance and identify areas for improvement?

To measure and track production performance and identify areas for improvement, I use the following techniques:

- Key Performance Indicators (KPIs): Establishing clear production KPIs, such as lead times, throughput, and quality metrics, to monitor performance.

- Data Analysis: Analyzing production data to identify trends, patterns, and areas for improvement, using tools such as statistical process control (SPC) and Six Sigma.

- Employee Feedback: Regularly soliciting feedback from production operators to gather insights into challenges and potential areas for optimization.

- Benchmarking: Comparing production performance to industry benchmarks and best practices to identify areas for further improvement.

8. How do you collaborate with other departments, such as Engineering, Quality Control, and Sales, to ensure smooth production operations?

Collaboration with other departments is crucial for smooth production operations. I foster strong relationships and employ the following strategies:

- Regular Meetings: Scheduling regular cross-functional meetings to discuss production schedules, quality issues, and customer requirements.

- Open Communication: Establishing open lines of communication and promoting transparency to facilitate seamless information flow.

- Joint Problem Solving: Collaborating with other departments to identify and resolve production challenges, ensuring a comprehensive and effective approach.

- Process Alignment: Working with stakeholders to align production processes with the overall business strategy and customer needs.

9. How do you balance production demands with customer requirements and quality standards?

Balancing production demands with customer requirements and quality standards is crucial. I prioritize the following approaches:

- Customer Focus: Maintaining a customer-centric mindset and understanding their specific requirements and expectations.

- Quality Assurance: Ensuring that production processes adhere to established quality standards and specifications.

- Production Flexibility: Adjusting production schedules and capacity to meet changing customer demands while maintaining quality.

- Communication: Collaborating with customers to manage expectations, provide updates, and address any concerns promptly.

10. Describe your experience in managing supply chain relationships and ensuring timely delivery of materials.

Supply chain management is vital for production efficiency. I approach it through:

- Supplier Selection: Identifying and partnering with reliable suppliers who meet quality and delivery requirements.

- Inventory Management: Implementing efficient inventory control systems to ensure adequate stock levels and minimize supply chain disruptions.

- Supplier Communication: Maintaining open communication with suppliers to track orders, identify potential delays, and develop contingency plans.

- Contingency Planning: Developing and implementing contingency plans to mitigate supply chain risks and ensure timely delivery of materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spring Production Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spring Production Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Spring Production Supervisor, your key responsibilities will include:

1. Managing Production Operations

Directing all aspects of production operations, including scheduling, staffing, and resource allocation.

- Developing and implementing production plans to meet customer demand.

- Ensuring that production schedules are met and that products are manufactured according to specifications.

2. Quality Control

Developing and implementing quality control procedures to ensure that products meet customer expectations.

- Inspecting incoming materials and finished products to ensure that they meet specifications.

- Identifying and resolving quality issues.

3. Safety and Compliance

Ensuring that all production operations are conducted in a safe and compliant manner.

- Establishing and enforcing safety protocols.

- Providing training on safety procedures to employees.

4. Team Leadership

Leading and motivating a team of production employees.

- Providing performance feedback to team members.

- Mentoring and developing employees.

5. Communication and Reporting

Communicating effectively with customers, staff, management, and other departments.

- Keeping management informed of production progress and issues.

- Preparing reports on production activities and performance.

Interview Tips

Here are some tips to help you ace your interview for a Spring Production Supervisor position:

1. Research the Company

Learn about the company’s history, mission, values, and products. This will show the interviewer that you are interested in the position and that you have taken the time to prepare.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to your network to see if anyone knows someone who works at the company.

2. Highlight Your Experience

Make sure to highlight your experience in production management, quality control, safety, and team leadership. Use specific examples to demonstrate your skills and abilities.

- For example, you might talk about a time when you developed and implemented a new production process that improved efficiency by 15%.

3. Show Your Passion

Let the interviewer know why you are passionate about production supervision. What drives you to succeed in this field?

- For example, you might talk about how you enjoy the challenge of managing a team and ensuring that products meet customer expectations.

4. Ask Questions

Asking thoughtful questions is a great way to show the interviewer that you are engaged and interested in the position. It also gives you a chance to learn more about the company and the role.

- Some good questions to ask include:

- What are the biggest challenges facing the production department right now?

- What are the company’s goals for the next year? How can I contribute to achieving these goals?

- What is the company’s culture like? What are the values that are important to the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spring Production Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!