Are you gearing up for an interview for a Squaring Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Squaring Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

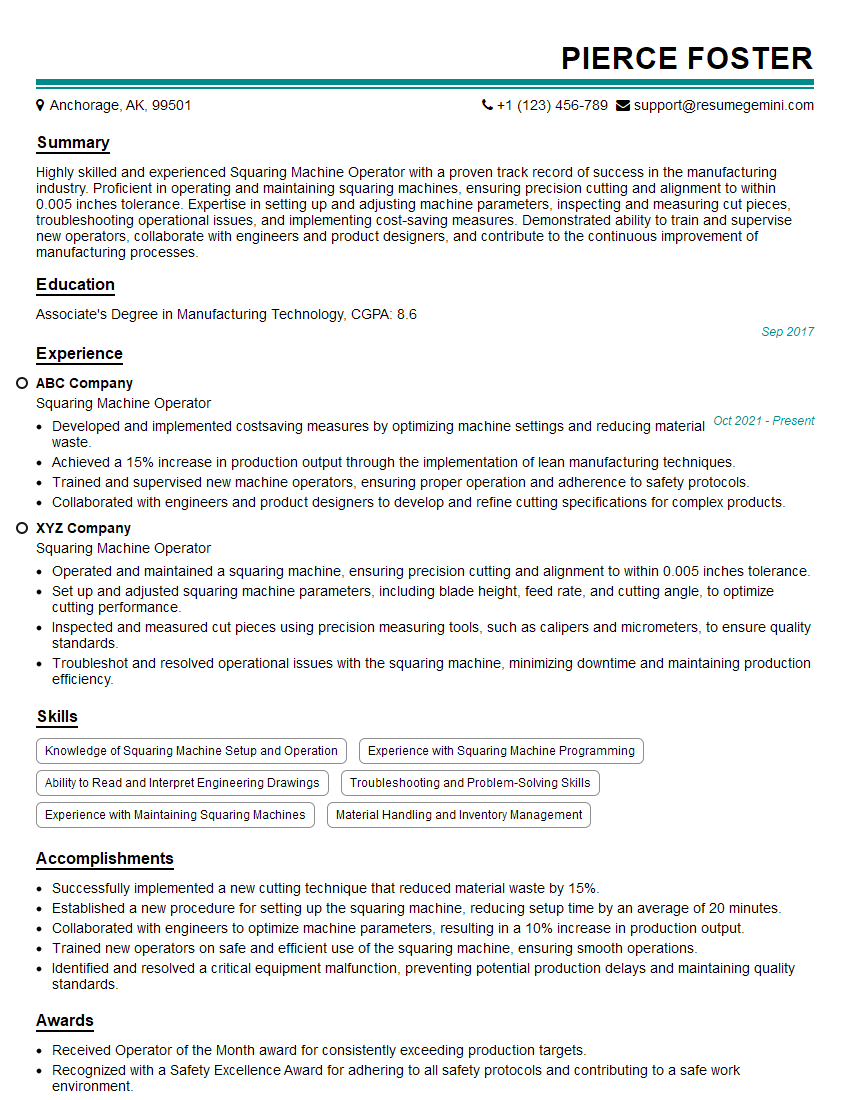

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Squaring Machine Operator

1. How do you maintain the accuracy of the squaring machine?

- Regularly calibrate the machine using precision measuring tools.

- Inspect and adjust the cutting blades and other components for wear and tear.

- Follow established setup procedures to ensure consistent and accurate cuts.

2. Describe the steps involved in setting up a job on the squaring machine.

Material Preparation

- Check material specifications and ensure it meets requirements.

- Clean and inspect the material surface for any defects or contaminants.

Machine Setup

- Secure the material onto the machine table using clamps or fixtures.

- Set the cutting blade depth and angle according to the job specifications.

- Adjust the feed rate and speed to optimize cutting efficiency and quality.

3. How do you troubleshoot common problems with the squaring machine?

- Identify the source of the problem by observing machine operations and error messages.

- Check for loose connections, damaged components, or improper settings.

- Refer to technical manuals and consult with experienced operators to find solutions.

4. How do you ensure the safety of yourself and others while operating the squaring machine?

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Keep the work area clean and organized to prevent tripping hazards.

- Never operate the machine while under the influence of drugs or alcohol.

5. What maintenance tasks do you perform on the squaring machine?

- Lubricate moving parts regularly to reduce friction and wear.

- Clean the machine table and other surfaces to remove debris and ensure smooth operation.

- Inspect the cutting blades, belts, and hydraulic system for any damage or signs of wear.

6. How do you calculate the cutting capacity of the squaring machine?

- Consider the machine’s horsepower and the material’s thickness.

- Refer to manufacturer’s specifications or use formula: Cutting capacity = K x Hp x T

- Where K is a constant, Hp is motor horsepower, and T is material thickness.

7. What are the different types of squaring machines, and what is their purpose?

- Hydraulic Squaring Machines: For high-volume production with heavy-duty materials.

- Mechanical Squaring Machines: Suitable for smaller jobs and lighter materials.

- Beam Squaring Machines: Used for large-scale shearing and plate cutting.

8. How do you maintain sharp and durable cutting blades on the squaring machine?

- Properly sharpen the blades using a grinding wheel or blade sharpener.

- Clean and lubricate the blades regularly to prevent corrosion and wear.

- Ensure correct blade alignment to minimize blade breakage.

9. What methods do you use to handle and store materials before and after squaring operations?

- Use lifting equipment, such as hoists or forklifts, for heavy materials.

- Store materials in designated areas to prevent damage and contamination.

- Protect materials from moisture and other environmental factors.

10. How do you improve the productivity and efficiency of squaring operations?

- Optimize machine settings and use proper cutting techniques.

- Minimize setup times and reduce material handling.

- Train operators on best practices and maintenance procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Squaring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Squaring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Squaring Machine Operator is an integral part of a metal fabrication team, playing a crucial role in cutting and shaping sheet metal components to precise specifications. Their expertise and efficiency contribute to the overall productivity and quality of the final product.

1. Machine Operation and Maintenance

• Setting up and operating squaring machines to cut sheet metal according to designated dimensions and angles.

• Monitoring machine operation, ensuring precise cutting and minimizing material waste.

• Performing regular maintenance and calibration to ensure optimal machine performance.

2. Material Handling and Inspection

• Loading and unloading sheet metal onto the squaring machine efficiently.

• Visually inspecting cut pieces for accuracy, ensuring they meet specified tolerances.

• Identifying and resolving any discrepancies or defects promptly.

3. Production Planning and Coordination

• Understanding job orders and determining optimal cutting sequences to maximize efficiency.

• Coordinating with other team members to ensure a smooth flow of materials and production.

• Documenting production details and maintaining records for quality control.

4. Safety and Compliance

• Prioritizing safety by adhering to established protocols and operating machinery cautiously.

• Maintaining a clean and organized work area to prevent accidents and ensure efficiency.

• Complying with all relevant health and safety regulations.

Interview Preparation Tips

Thorough preparation is key to standing out in an interview for a Squaring Machine Operator position. Here are some valuable tips to help candidates ace the interview and secure the job.

1. Research the Company and Industry

• Gather information about the company’s products, services, and industry standing.

• Familiarize yourself with current trends and advancements in the metal fabrication industry.

• This knowledge demonstrates your interest in the field and aligns your skills with the company’s goals.

2. Highlight Relevant Experience and Skills

• Emphasize your experience operating squaring machines, including the specific types of machines you’ve worked with.

• Quantify your accomplishments, using specific metrics to showcase your efficiency and quality.

• Showcase your ability to read blueprints, interpret specifications, and maintain a high level of precision.

3. Technical Expertise and Troubleshooting

• Describe your understanding of squaring machine functions, cutting techniques, and material properties.

• Prepare examples of troubleshooting situations you’ve encountered and how you resolved them.

• This demonstrates your technical aptitude and problem-solving abilities.

4. Safety and Compliance

• Emphasize your commitment to safety by highlighting your adherence to established protocols.

• Discuss your knowledge of relevant health and safety regulations.

• Showcase your understanding of maintaining a clean and organized work area.

Next Step:

Now that you’re armed with the knowledge of Squaring Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Squaring Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini