Are you gearing up for a career in Squaring Shear Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Squaring Shear Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

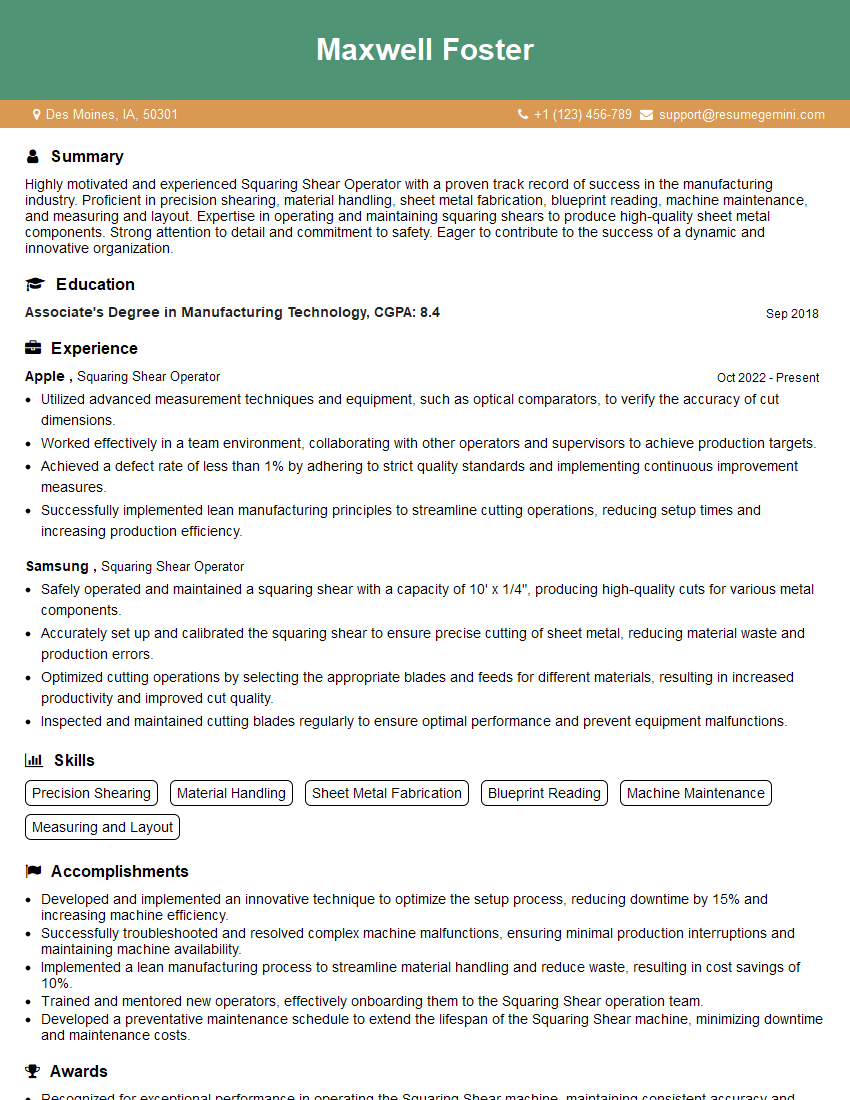

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Squaring Shear Operator

1. Explain the process of squaring shear operation?

The squaring shear operation involves using a machine to cut sheet metal into square or rectangular shapes. The process typically involves the following steps:

- Material selection: The first step is to select the sheet metal to be cut. The thickness and type of metal will determine the settings on the squaring shear.

- Machine setup: The next step is to set up the squaring shear. This involves adjusting the blade gap, hold-down pressure, and cutting angle.

- Material positioning: The sheet metal is then positioned on the squaring shear table. The material should be aligned with the desired cutting line.

- Cutting: Once the material is positioned, the operator engages the cutting mechanism. The blade descends and cuts through the metal, creating a clean and precise edge.

- Part removal: After the cut is complete, the operator removes the finished part from the squaring shear table.

2. What are the key factors to consider when setting up a squaring shear?

Factors to consider when setting up a squaring shear:

- Blade gap: The blade gap is the distance between the upper and lower blades. It should be set according to the thickness of the material being cut.

- Hold-down pressure: The hold-down pressure is the force that holds the material in place during cutting. It should be set high enough to prevent the material from slipping, but not so high that it deforms the material.

- Cutting angle: The cutting angle is the angle at which the upper blade meets the lower blade. It should be set according to the type of material being cut.

Additional factors to consider:

- Material thickness: The thickness of the material will determine the power required for cutting.

- Material type: The type of material will affect the cutting speed and blade life.

- Desired cut quality: The desired cut quality will determine the blade sharpness and cutting speed.

3. What are the different types of squaring shears?

There are two main types of squaring shears:

- Mechanical squaring shears: Mechanical squaring shears use a mechanical drive to power the cutting mechanism. They are typically used for cutting thinner materials.

- Hydraulic squaring shears: Hydraulic squaring shears use a hydraulic drive to power the cutting mechanism. They are typically used for cutting thicker materials.

4. What are the safety precautions that should be taken when operating a squaring shear?

Here are the important safety precautions that should be followed when operating a squaring shear:

- Wear appropriate safety gear, including safety glasses, gloves, and ear protection.

- Inspect the squaring shear before each use to ensure that it is in good working condition.

- Make sure that the material is securely positioned on the squaring shear table.

- Keep your hands and fingers away from the cutting blades.

- Never reach over the cutting blades.

- Be aware of the potential for flying debris and take appropriate precautions.

- Follow all manufacturer’s instructions for safe operation.

5. How do you maintain a squaring shear?

Here are some tips for maintaining a squaring shear:

- Clean the squaring shear regularly to remove any metal chips or debris.

- Inspect the blades regularly for wear or damage. If the blades are dull or damaged, they should be sharpened or replaced.

- Lubricate the squaring shear according to the manufacturer’s instructions.

- Check the hydraulic system regularly for leaks or other problems.

- Follow all manufacturer’s instructions for maintenance.

6. What are the common problems that can occur with a squaring shear?

Here are some of the common problems that can occur with a squaring shear:

- Dull or damaged blades: Dull or damaged blades can cause the squaring shear to cut unevenly or produce burrs.

- Misaligned blades: Misaligned blades can cause the squaring shear to cut inaccurately.

- Hydraulic leaks: Hydraulic leaks can cause the squaring shear to lose power or operate erratically.

- Electrical problems: Electrical problems can cause the squaring shear to malfunction.

7. How do you troubleshoot a squaring shear?

To troubleshoot a squaring shear, start by checking the following:

- Power supply: Make sure that the squaring shear is properly connected to a power source.

- Hydraulic system: Check the hydraulic system for leaks or other problems.

- Electrical system: Check the electrical system for loose connections or other problems.

- Blades: Inspect the blades for wear or damage. If the blades are dull or damaged, they should be sharpened or replaced.

If you are unable to troubleshoot the problem yourself, contact a qualified technician.

8. What is the difference between a squaring shear and a guillotine shear?

The main difference between a squaring shear and a guillotine shear is the way that the material is held in place during cutting.

- Squaring shear: A squaring shear uses a hold-down clamp to hold the material in place during cutting.

- Guillotine shear: A guillotine shear uses a gravity-fed system to hold the material in place during cutting.

Squaring shears are typically used for cutting thinner materials, while guillotine shears are typically used for cutting thicker materials.

9. What is the maximum thickness of material that a squaring shear can cut?

The maximum thickness of material that a squaring shear can cut depends on the power of the machine and the type of material being cut.

Typically, squaring shears can cut materials up to 1/4 inch thick.

10. What are the advantages of using a squaring shear?

There are several advantages to using a squaring shear, including:

- Accuracy: Squaring shears can produce very accurate cuts.

- Speed: Squaring shears can cut materials quickly and efficiently.

- Versatility: Squaring shears can be used to cut a variety of materials, including sheet metal, plastic, and rubber.

- Safety: Squaring shears are relatively safe to operate, as long as the proper safety precautions are followed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Squaring Shear Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Squaring Shear Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Squaring Shear Operators play a crucial role in the manufacturing industry, operating squaring shear machines to cut metal sheets to precise dimensions. Their key responsibilities encompass:

1. Machine Operation

Mastering the operation of squaring shear machines, ensuring accurate and efficient sheet metal cutting.

- Setting up and calibrating the machine according to job specifications.

- Loading, positioning, and securing metal sheets onto the machine.

- Operating the shear to cut sheets to specified dimensions and tolerances.

2. Quality Control

Maintaining high quality standards by inspecting cut sheets for accuracy, burrs, and other defects.

- Visually inspecting cut sheets for dimensional accuracy and surface finish.

- Using measuring tools to verify dimensions meet specifications.

- Identifying and correcting any deviations from quality standards.

3. Material Handling

Managing the safe and efficient handling of metal sheets and cut pieces.

- Loading and unloading metal sheets from the machine using proper lifting techniques.

- Sorting and stacking cut pieces according to job specifications.

- Maintaining a clean and organized work area.

4. Maintenance and Troubleshooting

Performing basic maintenance and troubleshooting on squaring shear machines.

- Conducting regular inspections and cleaning to prevent breakdowns.

- Identifying and resolving minor operational issues.

- Reporting major issues to supervisors for timely repairs.

Interview Tips

To ace the interview for a Squaring Shear Operator position, consider the following preparation tips:

1. Technical Knowledge

Thoroughly review the operating principles and safety procedures of squaring shear machines.

- Be prepared to discuss different types of squaring shears and their applications.

- Demonstrate knowledge of cutting techniques, blade selection, and machine maintenance.

2. Practical Experience

Highlight your hands-on experience in operating squaring shear machines.

- Quantify your achievements in terms of production output, quality control, and adherence to safety protocols.

- Provide specific examples of how you resolved operational challenges and improved efficiency.

3. Attention to Detail

Emphasize your keen eye for detail and commitment to producing high-quality work.

- Explain how you carefully inspect cut sheets for dimensional accuracy and surface finish.

- Describe your techniques for ensuring that cut pieces meet customer specifications.

4. Problem-Solving Abilities

Demonstrate your ability to troubleshoot and resolve operational issues.

- Describe a situation where you identified and rectified a problem with a squaring shear machine.

- Explain how you handle unexpected challenges and maintain productivity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Squaring Shear Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Squaring Shear Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.