Feeling lost in a sea of interview questions? Landed that dream interview for Stainless Steel Finisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Stainless Steel Finisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

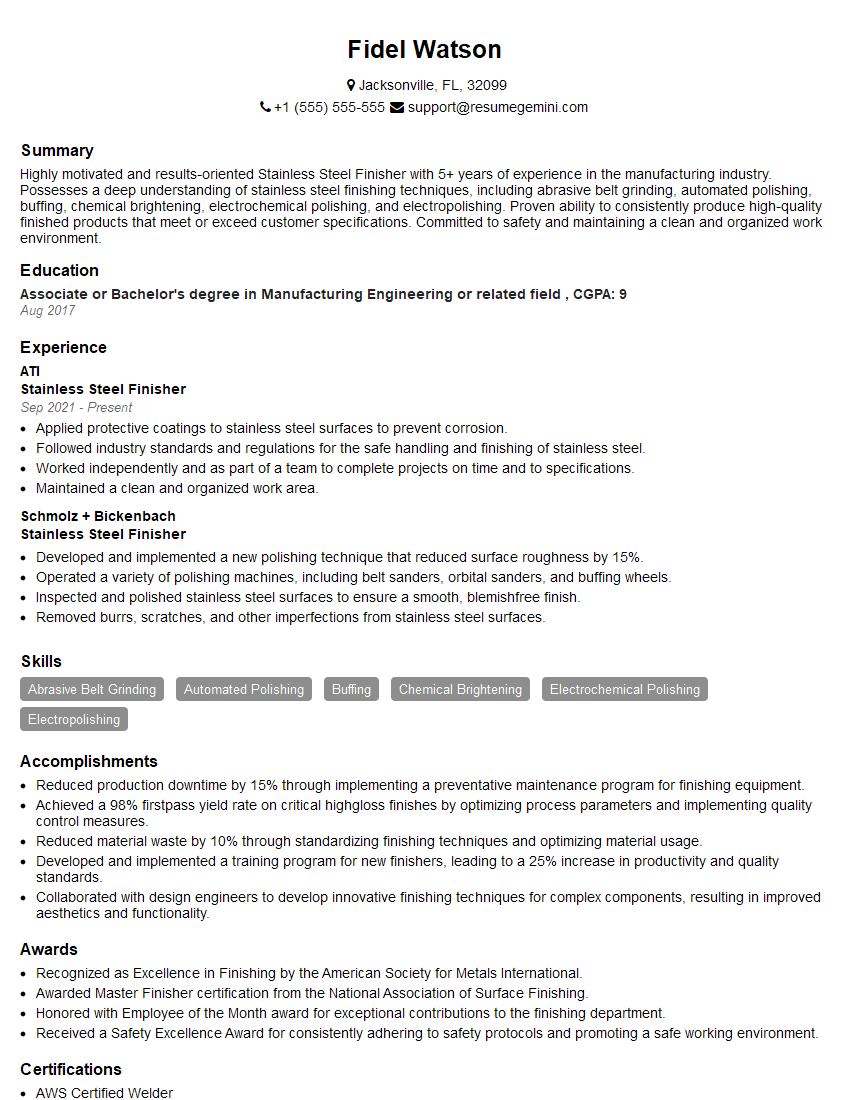

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stainless Steel Finisher

1. What are the different types of stainless steel finishes available? Describe their properties and applications.

As a Stainless Steel Finisher, I am familiar with a wide range of stainless steel finishes, each with its own unique properties and applications:

- No. 2B Finish (Cold Rolled): This is a matte finish, created by cold rolling the stainless steel. It offers good corrosion resistance and is often used in architectural applications, such as cladding and roofing.

- No. 4 Finish (Brushed): This finish is created by mechanically brushing the stainless steel surface, resulting in a uniform, directional grain. It is a popular choice for decorative applications, such as kitchen appliances and furniture.

- No. 7 Finish (High Gloss): This is a highly reflective finish, achieved by polishing the stainless steel surface to a mirror-like shine. It is commonly used in applications where a high degree of reflectivity is desired, such as automotive trim and jewelry.

- No. 8 Finish (Satin): This finish is created by mechanically abrading the stainless steel surface, resulting in a smooth, non-directional grain. It is often used in applications where a combination of durability and aesthetics is required, such as kitchen countertops and medical equipment.

- No. 10 Finish (Bead Blasted): This finish is created by blasting the stainless steel surface with tiny glass beads. It results in a uniform, matte texture with a slight reflective quality. It is commonly used in applications where a non-slip surface is required, such as flooring and handrails.

2. What are the key factors that determine the surface quality of a stainless steel finish?

The surface quality of a stainless steel finish is determined by several key factors:

Surface Preparation

- The initial surface condition of the stainless steel, including its roughness and cleanliness, plays a crucial role in determining the final finish quality.

- Proper surface preparation involves removing any imperfections, such as scratches or burrs, to ensure a smooth and even surface for finishing.

Finishing Process

- The type of finishing process used, whether mechanical or chemical, influences the surface texture and appearance.

- Proper technique, equipment, and process parameters are essential to achieve a consistent and high-quality finish.

Post-Finishing Treatment

- Post-finishing treatments, such as passivation or electropolishing, can further enhance the surface quality by improving corrosion resistance and reducing surface roughness.

- These treatments help protect the finish and maintain its appearance over time.

3. Describe the process of electropolishing stainless steel and explain its advantages.

Electropolishing is an electrochemical process that involves submerging the stainless steel in an electrolyte solution and applying an electric current. This process removes a thin layer of metal from the surface, resulting in a highly polished and passivated finish:

- Advantages of Electropolishing

- Improved corrosion resistance

- Reduced surface roughness and improved smoothness

- Enhanced aesthetic appeal due to high reflectivity

- Removal of burrs and other surface imperfections

- Increased biocompatibility, making it suitable for medical applications

4. What are the different methods used to protect stainless steel surfaces from corrosion?

Several methods are commonly used to protect stainless steel surfaces from corrosion:

- Passivation: This process involves exposing the stainless steel surface to a mild acid solution, which removes surface contaminants and forms a protective oxide layer.

- Electropolishing: As mentioned earlier, electropolishing not only provides a high-quality finish but also enhances corrosion resistance by removing surface imperfections and promoting passivation.

- Coating: Applying protective coatings, such as epoxy or polyurethane, can create a barrier between the stainless steel surface and corrosive environments.

- Alloying: Adding certain alloying elements, such as molybdenum or nitrogen, to the stainless steel composition can enhance its inherent corrosion resistance.

5. Describe the importance of grain size in stainless steel finishing.

Grain size plays a crucial role in the finishing process of stainless steel:

- Smaller grain sizes result in a smoother and more uniform surface finish.

- Larger grain sizes can create a more textured or matte finish.

- Controlling the grain size during the manufacturing process allows for precise tailoring of the final surface appearance.

6. How do you handle and store stainless steel sheets to prevent surface damage?

Proper handling and storage techniques are essential to prevent surface damage to stainless steel sheets:

- Handling: Using gloves or clean cloths when handling stainless steel sheets helps prevent fingerprints and smudges.

- Storage: Storing sheets in a dry and well-ventilated environment, away from corrosive substances, prevents moisture and contamination.

- Interleaving: Interleaving sheets with protective paper or plastic film helps prevent scratches and abrasions during storage and transportation.

7. What safety precautions should be taken when working with stainless steel finishing chemicals?

Working with stainless steel finishing chemicals requires adherence to strict safety precautions:

- Proper Ventilation: Ensuring adequate ventilation is crucial to prevent inhalation of hazardous fumes.

- Protective Gear: Wearing appropriate personal protective equipment, including gloves, respirators, and eye protection, is essential.

- Chemical Handling: Following recommended handling instructions and using appropriate containers to avoid spills and contamination.

- Disposal: Disposing of chemicals and waste products according to established environmental regulations is imperative.

8. How do you stay updated with the latest advancements in stainless steel finishing techniques?

Staying abreast of the latest advancements in stainless steel finishing techniques is crucial for maintaining proficiency:

- Industry Publications: Reading trade journals and attending industry conferences allows me to stay informed about new technologies and best practices.

- Manufacturer Training: Participating in training programs offered by equipment manufacturers provides hands-on experience and knowledge of their latest innovations.

- Online Resources: Exploring websites, forums, and technical articles offers access to valuable information and insights.

9. Describe a challenging stainless steel finishing project you have worked on and how you overcame the challenges.

In a recent project, I encountered a complex stainless steel architectural cladding with intricate patterns and tight tolerances. The challenge lay in achieving a uniform and high-quality finish across the entire surface.

To overcome this, I collaborated with the design team to optimize the finishing process and developed a customized approach involving a combination of mechanical brushing and electropolishing. The result was a flawless finish that met the stringent aesthetic and performance requirements.

10. What are your strengths and weaknesses as a Stainless Steel Finisher?

My key strengths include:

- Proficient in various stainless steel finishing techniques, including mechanical brushing, electropolishing, and passivation.

- Strong understanding of the properties and applications of different stainless steel finishes.

- Meticulous attention to detail and commitment to delivering high-quality results.

As for areas for improvement, I am constantly seeking opportunities to enhance my knowledge and expand my skillset in advanced finishing techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stainless Steel Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stainless Steel Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stainless Steel Finisher is responsible for a variety of tasks related to the finishing of stainless steel products. These tasks may include:

1. Preparing the Surface

Before the finishing process can begin, the surface of the stainless steel must be prepared. This typically involves cleaning and degreasing the surface to remove any contaminants. The surface may also need to be sanded or ground to achieve the desired smoothness.

- Clean and degrease the surface of the stainless steel

- Sand or grind the surface to achieve the desired smoothness

- Apply a chemical treatment to the surface to improve its corrosion resistance

- Use a buffing wheel to polish the surface to a high shine

2. Applying the Finish

Once the surface has been prepared, the finisher can begin applying the desired finish. This may involve using a variety of techniques, such as polishing, brushing, or bead blasting. The type of finish that is applied will depend on the desired appearance and the intended use of the product.

- Polish the surface to a high shine

- Brush the surface to create a matte finish

- Bead blast the surface to create a textured finish

- Apply a clear coat to protect the finish

3. Inspecting the Finished Product

Once the finishing process is complete, the finisher will inspect the product to ensure that it meets the desired quality standards. This may involve checking the surface for any defects, such as scratches or dents. The finisher may also need to test the product’s corrosion resistance.

- Inspect the finished product for any defects

- Test the product’s corrosion resistance

- Make any necessary adjustments to the finishing process

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

- Prepare questions to ask the interviewer

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Situation: Describe a situation that is relevant to the question.

- Task: Describe the task that you were responsible for completing.

- Action: Describe the actions that you took to complete the task.

- Result: Describe the results of your actions.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows that you are respectful of the interviewer’s time.

- Dress in a suit or business casual attire

- Be punctual

- Be polite and respectful

4. Follow Up After the Interview

After the interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you are serious about your application. You can follow up by sending a thank-you note or by calling the interviewer to check on the status of your application.

- Send a thank-you note within 24 hours of the interview

- Call the interviewer to check on the status of your application after a week or two

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stainless Steel Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!