Feeling lost in a sea of interview questions? Landed that dream interview for Stamp Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Stamp Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

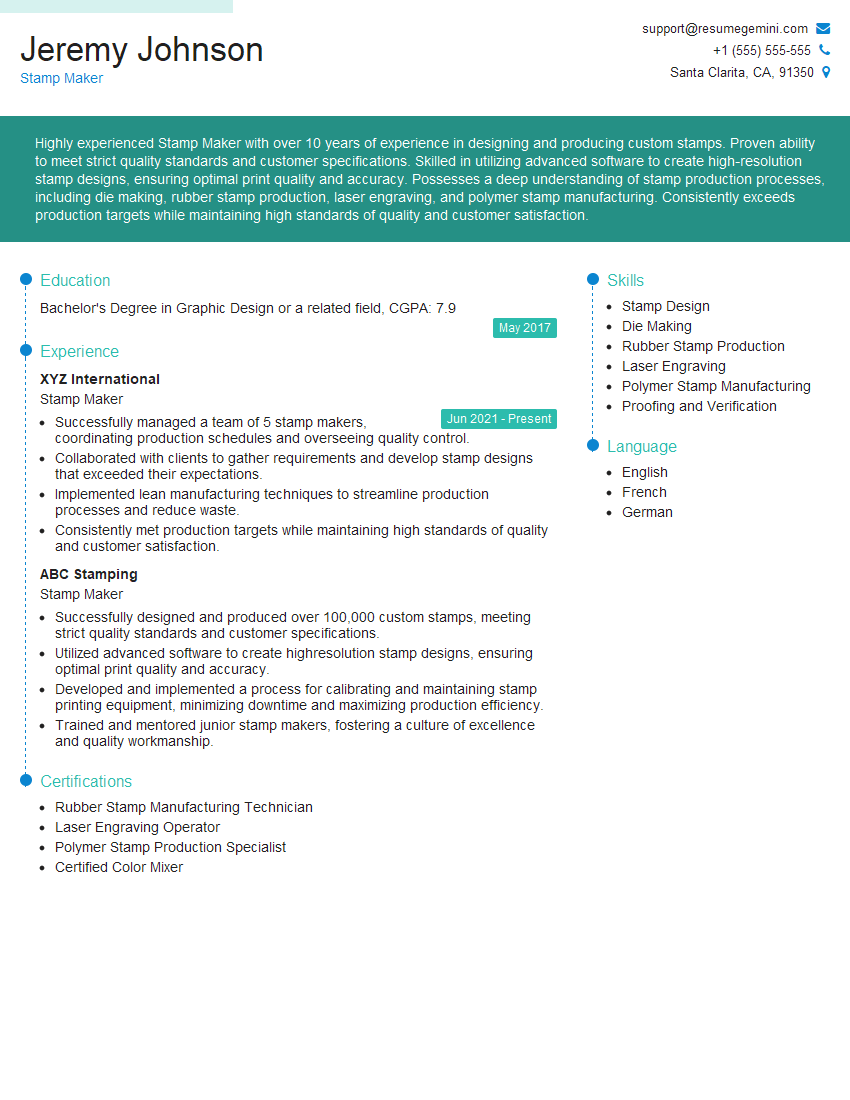

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stamp Maker

1. How would you ensure that the stamps you create meet the required technical specifications?

- Maintain a high level of precision and accuracy when following design specifications.

- Utilize software and tools that enable precise measurements and control over design elements.

- Conduct thorough quality control checks at various stages of production to identify and correct any deviations from specifications.

- Regularly calibrate equipment and machinery to maintain optimal performance and accuracy.

- Collaborate with engineers and other relevant personnel to ensure that designs are both aesthetically pleasing and technically sound.

2. Describe your experience in operating different types of stamp-making machinery and explain how you ensure their proper maintenance and calibration.

Maintenance

- Regularly clean and lubricate machinery according to manufacturer’s instructions.

- Inspect equipment for wear and tear, identifying and replacing worn parts promptly.

- Monitor machinery performance and usage to predict potential issues and schedule maintenance accordingly.

- Maintain a clean and organized work area to prevent accidents and preserve equipment longevity.

- Adhere to safety protocols and wear appropriate protective gear when operating machinery.

Calibration

- Use precision measuring tools to ensure that machinery is calibrated to exact specifications.

- Follow established calibration procedures and maintain records of calibration dates and results.

- Collaborate with technicians or external service providers for specialized calibration tasks.

- Verify calibration accuracy by conducting test runs and comparing results to known standards.

- Stay updated on industry best practices and technological advancements in machinery maintenance and calibration.

3. How would you approach a situation where a customer requires a custom stamp design that is outside of your current skillset?

- Communicate openly with the customer to understand their specific requirements and design vision.

- Research and explore different techniques and technologies to determine feasibility.

- Collaborate with other designers or seek external expertise if necessary.

- Present multiple design options to the customer, explaining the advantages and limitations of each.

- Work closely with the customer to refine the design and ensure their satisfaction.

4. Can you describe your understanding of the different materials used in stamp production and how their properties influence the final product?

- Rubber: Durable, versatile, and provides a crisp impression; suitable for both hand and machine stamping.

- Polymer: Lightweight, economical, and produces high-quality impressions; often used for intricate designs.

- Metal: Long-lasting, suitable for heavy-duty applications; used for official seals and industrial marking.

- Wood: Classic and aesthetically pleasing, but requires careful handling and may not be as durable as other materials.

- Acrylic: Clear and shatter-resistant, allowing for precise alignment and visibility; commonly used for photopolymer stamps.

5. How do you stay updated on the latest trends and advancements in stamp-making technology?

- Attend industry conferences and trade shows.

- Read specialized publications and online resources.

- Network with other professionals in the field.

- Experiment with new techniques and materials.

- Seek opportunities for professional development and training.

6. Can you explain the process of creating a stamp from scratch, including design, production, and quality control?

Design

- Develop or receive a design concept.

- Create a digital or physical prototype.

- Refine the design based on feedback and specifications.

Production

- Select appropriate materials and machinery.

- Transfer the design to the stamp material.

- Produce the stamp through processes such as laser engraving, rubber molding, or photopolymer exposure.

Quality Control

- Inspect the stamp for defects or errors.

- Test the stamp to ensure proper functionality and impression quality.

- Make necessary adjustments or corrections based on inspection results.

7. How would you handle a situation where a customer is not satisfied with the final product?

- Listen attentively to the customer’s concerns and feedback.

- Review the product and identify any areas that may have fallen short of expectations.

- Communicate openly and honestly with the customer, explaining the reasons for any discrepancies.

- Explore possible solutions, such as redesigning the stamp, using alternative materials, or providing a refund.

- Prioritize customer satisfaction and strive to resolve the issue in a mutually agreeable manner.

8. How do you ensure that your stamps meet the highest quality standards?

- Utilize high-quality materials and equipment.

- Follow precise production processes and adhere to industry standards.

- Conduct thorough quality control inspections at multiple stages of production.

- Seek feedback from customers and continuously improve processes based on their input.

- Stay updated on the latest technological advancements in stamp-making to enhance quality.

9. What safety precautions do you take when operating stamp-making machinery?

- Wear appropriate safety gear, such as gloves and eye protection.

- Ensure proper ventilation to prevent exposure to fumes or dust.

- Maintain a clean and organized work area to minimize tripping hazards.

- Follow established operating procedures and never bypass safety mechanisms.

- Receive regular training on safety protocols and emergency procedures.

10. How do you manage your time and prioritize tasks effectively in a fast-paced work environment?

- Create a structured schedule and prioritize tasks based on urgency and importance.

- Break down large projects into smaller, manageable tasks.

- Delegate responsibilities to team members when appropriate.

- Use technology to streamline tasks and improve efficiency.

- Take regular breaks to maintain focus and productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stamp Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stamp Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stamp Makers are skilled professionals responsible for creating custom stamps for various applications. Their duties encompass the following key areas:

1. Design and Creation

Design and create custom stamps based on client specifications and industry standards.

- Develop stamp designs that meet specific requirements, including size, shape, material, and ink color.

- Utilize specialized software and tools to produce high-quality stamp designs.

2. Production and Quality Control

Produce stamps using various production methods, including engraving, laser cutting, and photopolymerization.

- Ensure stamps meet specified tolerances and standards for precision and durability.

- Conduct quality control checks to identify and rectify any defects or errors.

3. Customer Service and Collaboration

Provide excellent customer service by understanding client needs and delivering personalized solutions.

- Collaborate with clients to develop customized stamp designs that meet their specific requirements.

- Address customer inquiries and provide technical support related to stamp usage and maintenance.

4. Industry Knowledge and Innovation

Stay abreast of industry trends and advancements in stamp making technology.

- Explore and implement innovative techniques to enhance stamp design and production processes.

- Research new materials and technologies to create unique and specialized stamps.

Interview Tips

To prepare effectively for a Stamp Maker interview, consider the following tips:

1. Research the Company and Position

Thoroughly research the company’s history, values, and product offerings. Understand the specific role you are applying for and its responsibilities.

- Visit the company website and social media pages.

- Review industry articles and publications to stay informed about the latest trends in stamp making.

2. Showcase Your Skills and Experience

Highlight your skills and experience in stamp design, production, and customer service. Provide specific examples of projects you have worked on and the results you achieved.

- Create a portfolio or online gallery to showcase your stamp designs and production techniques.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

3. Prepare Industry-Specific Questions

Demonstrate your industry knowledge by preparing questions about the latest advancements in stamp making technology or market trends. This shows your passion for the field and eagerness to stay updated.

- Ask about the company’s approach to sustainability in stamp production.

- Inquire about the types of specialized stamps they produce and the industries they serve.

4. Practice Common Interview Questions

Anticipate standard interview questions and prepare well-structured answers that highlight your qualifications. Use the STAR method (Situation, Task, Action, Result) to effectively describe your experiences.

- “Tell me about a time you faced a challenge in stamp production and how you overcame it.”

- “Describe a project where you successfully designed and produced a custom stamp for a client.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stamp Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!