Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Stamp Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Stamp Press Operator so you can tailor your answers to impress potential employers.

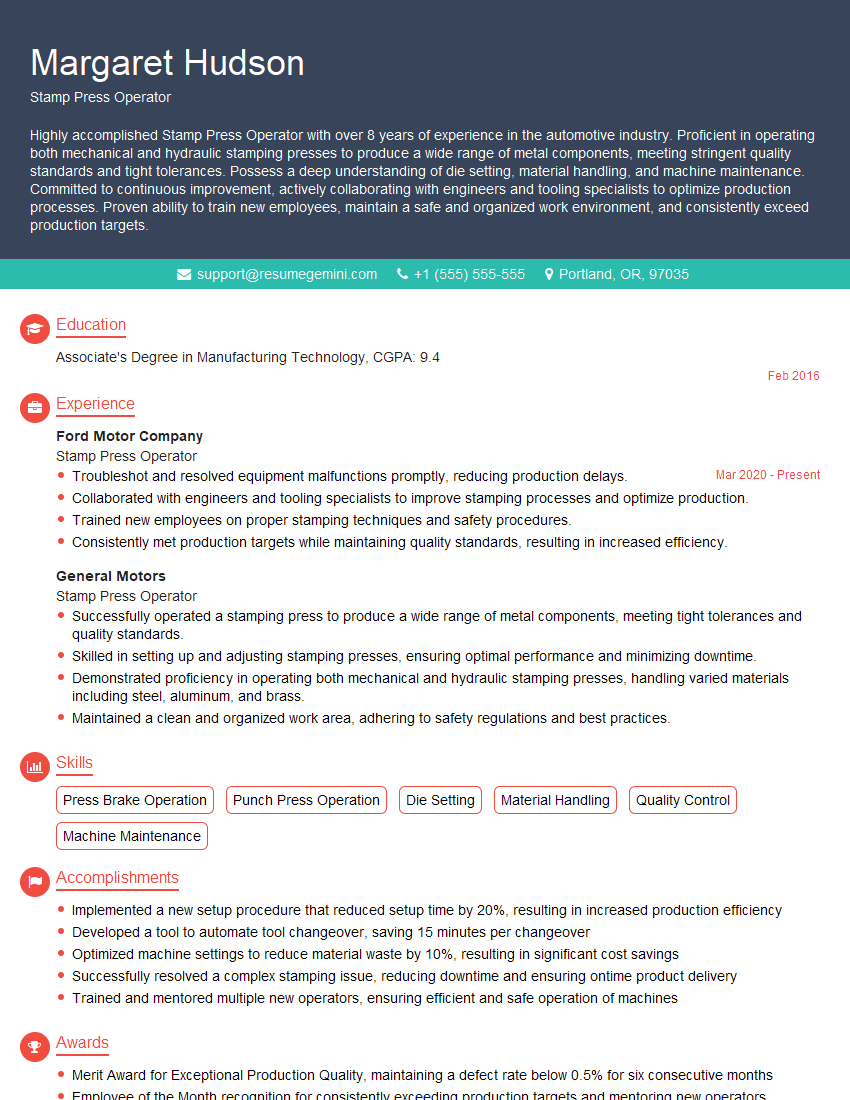

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stamp Press Operator

1. What are the different types of stamping presses and their applications?

There are various types of stamping presses, including:

- Mechanical presses: These presses use a flywheel and crankshaft to generate mechanical energy for stamping.

- Hydraulic presses: These presses use hydraulic fluid to generate pressure for stamping.

- Pneumatic presses: These presses use compressed air to generate force for stamping.

- Servo presses: These presses use a servo motor to control the movement of the ram, providing high precision and speed.

2. What are the key technical specifications to consider when selecting a stamping press?

- Tonnage capacity: The force exerted by the press, measured in tons.

- Bed size: The maximum size of the sheet metal that can be accommodated.

- Stroke length: The maximum distance the ram can travel.

- Speed: The number of strokes per minute that the press can achieve.

- Slide adjustment: The ability to adjust the position of the slide to accommodate various die heights.

3. Describe the process of die alignment and setup.

Die alignment and setup involve:

- Checking die clearance: Ensuring proper space between the punch and die to prevent jamming or damage.

- Adjusting the die set: Using shims or other components to align the punch and die concentrically.

- Proofing the die: Running a test cycle with a sample sheet to verify alignment and make any necessary adjustments.

4. How do you troubleshoot common stamping press issues, such as misfeeds, double feeds, and die breakage?

- Misfeeds: Inspect feed mechanisms, check for obstructions, and adjust feed rate.

- Double feeds: Examine feed timing, adjust feed controls, and check for damaged sensors.

- Die breakage: Check for excessive wear or damage to the punch or die, adjust tonnage capacity, and inspect die alignment.

5. How do you ensure the safety of the operator and maintain a clean and efficient work environment?

- Following safety protocols: Adhering to lockout/tagout procedures, wearing appropriate safety gear, and maintaining a clean workspace.

- Regularly inspecting equipment: Checking for potential hazards, such as loose wires or damaged components, and reporting any concerns promptly.

- Maintaining a tidy work area: Keeping tools and supplies organized, cleaning spills, and disposing of waste properly.

6. What is the role of preventive maintenance in optimizing stamping press performance?

- Regular lubrication: Greasing moving parts to minimize friction and wear.

- Inspection and adjustment: Checking for loose bolts, misalignment, and other issues, and making adjustments as needed.

- Replacement of worn components: Replacing worn or damaged parts to ensure optimal performance and prevent breakdowns.

7. How do you optimize the stamping process for different materials, such as steel, aluminum, and stainless steel?

- Adjusting tonnage capacity: Using the appropriate amount of force for the material thickness and hardness.

- Selecting the right die material: Choosing a die material that withstands the wear and tear of the specific material.

- Setting proper feed rate: Controlling the speed of the feed mechanism to prevent damage to the material.

8. What are the key quality control measures to ensure the precision and consistency of stamped parts?

- Dimensional inspection: Measuring the dimensions of the parts using calipers, micrometers, or other measuring tools.

- Visual inspection: Checking for surface defects, burrs, or other imperfections.

- Statistical process control: Monitoring the stamping process to identify and correct any deviations from specifications.

9. How do you work effectively in a team environment, and what is your approach to communication and cooperation?

- Clear communication: Actively listening to instructions, asking clarifying questions, and providing timely updates.

- Collaborative problem-solving: Working with colleagues to identify and resolve issues, sharing knowledge, and supporting each other.

- Teamwork orientation: Prioritizing team goals, contributing to a positive work environment, and respecting the skills and perspectives of others.

10. What are your career aspirations and how do you see this role contributing to your professional development?

- Aspirations: Expressing interest in advancing within the field, taking on leadership roles, or specializing in a specific area.

- Contribution: Explaining how the role aligns with your aspirations, providing opportunities for skill development, knowledge acquisition, and career growth.

- Continuous improvement: Emphasizing a commitment to ongoing learning, seeking feedback, and exploring new challenges to enhance professional capabilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stamp Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stamp Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stamp press operators play a crucial role in the manufacturing industry, using specialized stamping presses to shape and cut metal according to precise specifications. Their primary responsibilities include:

1. Machine Operation

They operate and calibrate stamping presses, ensuring proper setup and efficient functioning.

- Loading and unloading metal sheets or strips into the press

- Selecting and installing appropriate dies and tooling

2. Quality Control

Inspecting stamped parts to ensure dimensional accuracy, surface finish, and adherence to specifications.

- Using measuring instruments such as calipers and micrometers

- Identifying and rectifying defects or deviations

3. Production Maintenance

Performing basic maintenance and troubleshooting on stamping equipment to minimize downtime.

- Lubricating and cleaning presses

- Changing worn or damaged parts

4. Material Handling

Handling and moving heavy metal sheets or coils safely and efficiently.

- Using cranes or forklifts to transport materials

- Ensuring proper storage and inventory management

Interview Tips

To ace an interview for a stamp press operator position, candidates should consider the following preparation tips:

1. Research the Company

familiarize themselves with the company’s background, products or services, and industry standing.

- Visit the company’s website

- Read industry news and publications

2. Practice Common Interview Questions

Prepare answers to common interview questions, especially those related to stamp press operation, quality control, and troubleshooting.

- Describe your experience in operating stamping presses.

- Explain how you ensure the quality of stamped parts.

- Provide an example of a time you successfully resolved a press-related issue.

3. Highlight Relevant Skills

Emphasize skills and experience that are specific to the stamp press operator role, such as:

- Machine operation

- Quality control

- Troubleshooting

4. Demonstrate Safety Awareness

As stamp press operation involves handling heavy machinery, candidates should highlight their safety consciousness.

- Describe safety procedures followed in previous roles.

- Explain how they maintain a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stamp Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!