Are you gearing up for a career in Stamping Die Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Stamping Die Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

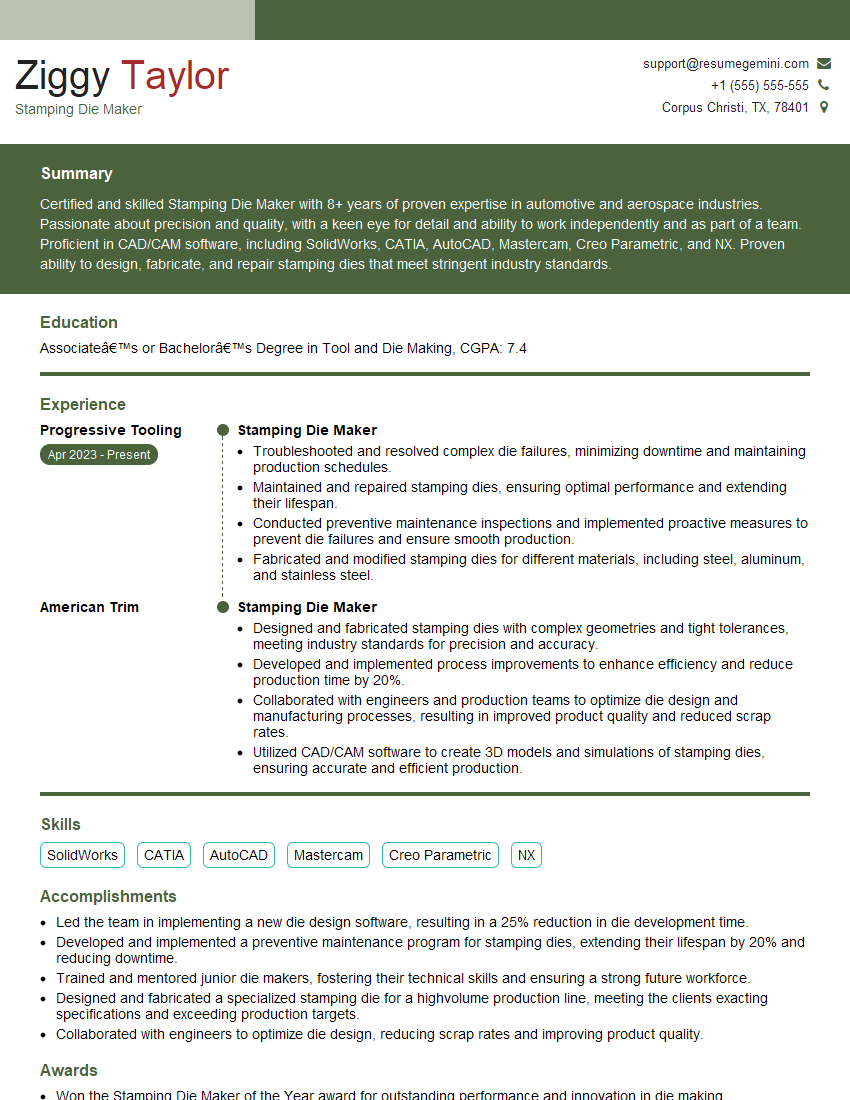

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stamping Die Maker

1. Describe the process of designing a stamping die, from concept to production.

The process of designing a stamping die involves several steps:

- Concept development: Understanding the product requirements and specifications.

- Feasibility analysis: Assessing the viability of the design and identifying potential challenges.

- Die design: Creating the detailed design of the die, including its geometry, materials, and components.

- Die simulation: Utilizing software to simulate the die operation and optimize its performance.

- Die manufacturing: Fabricating the die components and assembling them into the final product.

- Die testing: Conducting trials to verify that the die meets the desired specifications and produces high-quality parts.

2. Explain the principles of punch and die clearance.

Punch and die clearance refers to the gap between the punch and die during the stamping process.

Factors affecting clearance

- Material properties

- Thickness of the material

- Type of stamping operation (piercing, blanking, forming)

Effects of clearance

- Excessive clearance: Material deformation, burr formation

- Insufficient clearance: High cutting forces, die damage

3. Discuss the role of die materials in stamping operations.

Die materials play a crucial role in the performance and longevity of stamping dies.

- Tool steels: High hardness, wear resistance (e.g., A2, D2, H13)

- Carbide: Exceptional hardness, suitable for high-volume production (e.g., tungsten carbide, titanium carbide)

- Ceramics: High temperature tolerance, suitable for abrasive materials (e.g., silicon carbide, alumina)

- Polymers: Low cost, suitable for low-volume production or prototyping

4. Describe the different types of stamping presses and their applications.

Stamping presses come in various types, each suited for specific applications:

- Mechanical presses: Driven by a crankshaft or flywheel, suitable for high-speed operations

- Hydraulic presses: Utilize hydraulic pressure to generate force, ideal for precision forming and deep drawing

- Pneumatic presses: Powered by compressed air, suitable for small-scale or low-force applications

- Servo presses: Electrically driven, offering precise control and high repeatability

5. Explain the difference between progressive and transfer dies.

Progressive dies and transfer dies are two types of multi-station stamping dies:

Progressive dies

- Perform multiple operations in sequence within a single die

- Suit parts with complex shapes and precise tolerances

- Typically used for high-volume production

Transfer dies

- Transfer parts from station to station using a transfer mechanism

- Efficient for intricate parts requiring multiple forming steps

- Suitable for medium to high-volume production

6. Discuss the importance of die maintenance and how it affects die life.

Regular die maintenance is essential to extend the life of stamping dies and ensure optimal performance.

- Cleaning: Removing debris and lubricants from the die

- Lubrication: Applying lubricants to reduce friction and wear

- Inspection: Checking for damage, wear, or misalignment

- Adjustment: Making minor adjustments to ensure proper die operation

Benefits of die maintenance

- Increased die life

- Improved part quality

- Reduced downtime and production costs

7. Describe the techniques for troubleshooting common stamping defects.

Stamping defects can arise due to various factors, and troubleshooting requires a systematic approach:

- Identify the defect: Examine the part and determine the type of defect (e.g., burr, crack, distortion)

- Analyze potential causes: Consider factors such as die design, material, press settings, and lubrication

- Implement corrective actions: Adjust die settings, inspect and repair the die, or modify the material or process

- Verify the results: Conduct trial runs to ensure that the defect has been resolved

8. Explain the principles of finite element analysis (FEA) and its application in stamping die design.

FEA is a computational technique used to analyze the stress and deformation of dies under operating conditions.

Applications in die design

- Predicting die loads and stresses

- Optimizing die geometry for improved performance

- Identifying potential failure points and reducing the risk of die damage

- Simulating die-part interaction to improve part quality

9. Discuss the latest advancements in stamping die technology.

The stamping die industry is constantly evolving with new technologies emerging:

- Additive manufacturing: 3D printing to create complex die components with greater design freedom

- Advanced materials: Development of new materials with enhanced strength, wear resistance, and corrosion resistance

- Smart dies: Integration of sensors and actuators for real-time monitoring and control of die operation

- Digital twin technology: Creating virtual representations of dies to simulate performance and predict maintenance needs

10. Describe your experience with lean manufacturing principles and how you have applied them to die making.

Lean manufacturing aims to eliminate waste and improve efficiency:

Applications in die making

- Value stream mapping: Identifying and analyzing the flow of materials and processes involved in die making

- 5S: Organizing and standardizing the workplace to reduce waste and improve productivity

- Cellular manufacturing: Arranging workstations in a logical sequence to reduce material handling and improve workflow

- Kanban: Visual inventory control system to prevent overproduction and maintain a steady flow of materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stamping Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stamping Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Stamping Die Maker, you will be responsible for various tasks that contribute to the production of high-quality stamped parts. Here are some key responsibilities of this role:

1. Die Design and Development

You will work with engineers to design and develop stamping dies that meet specific product requirements. This involves understanding the part geometry, material properties, and production process.

- Analyze part drawings and specifications to determine die design.

- Use CAD/CAM software to create 3D models and detailed drawings of dies.

2. Die Manufacturing and Modification

You will be involved in the fabrication and modification of dies using various machine tools and techniques. This requires precision and attention to detail.

- Operate CNC machines, grinders, and other tools to produce die components.

- Assemble and inspect dies to ensure proper fit and function.

- Modify dies as needed to meet production requirements or address quality issues.

3. Maintenance and Repair

You will be responsible for maintaining and repairing stamping dies to ensure optimal performance and longevity. This involves regular inspection, cleaning, and lubrication.

- Inspect dies for wear, damage, or other issues.

- Perform preventive maintenance tasks to extend die life.

- Repair or replace damaged die components to minimize downtime.

4. Quality Assurance

You will be involved in monitoring and ensuring the quality of stamped parts produced using the dies. This requires understanding quality standards and inspection techniques.

- Inspect stamped parts for dimensional accuracy, surface finish, and other quality attributes.

- Identify and address quality issues by adjusting die settings or modifying the production process.

- Maintain quality control documentation and records.

Interview Tips

To prepare effectively for your interview as a Stamping Die Maker, consider these tips and hacks:

1. Research the Company and Industry

Gather information about the company, its products, and the stamping industry. This will demonstrate your interest and knowledge of the field.

- Visit the company website and read industry publications.

- Attend industry events or webinars to network and learn about trends.

2. Highlight Your Technical Skills

Emphasize your proficiency in die design, manufacturing, and maintenance. Quantify your experience and provide specific examples of projects you have worked on.

- Describe your experience using CAD/CAM software and CNC machines.

- Share examples of dies you have designed or modified that resulted in improved production efficiency or part quality.

3. Showcase Your Problem-Solving Abilities

Interviewers want to know how well you handle challenges. Prepare to discuss situations where you identified and resolved problems related to die design or production.

- Explain how you analyzed stamping defects and implemented solutions.

- Describe instances where you collaborated with engineers or production teams to troubleshoot issues.

4. Demonstrate Your Attention to Detail

Stamping die making requires precision and accuracy. Emphasize your attention to detail and ability to work with tight tolerances.

- Discuss your experience using precision measuring instruments and inspection techniques.

- Provide examples of how you ensured the accuracy and quality of stamped parts.

Next Step:

Now that you’re armed with the knowledge of Stamping Die Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Stamping Die Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini