Feeling lost in a sea of interview questions? Landed that dream interview for Staple Processing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Staple Processing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

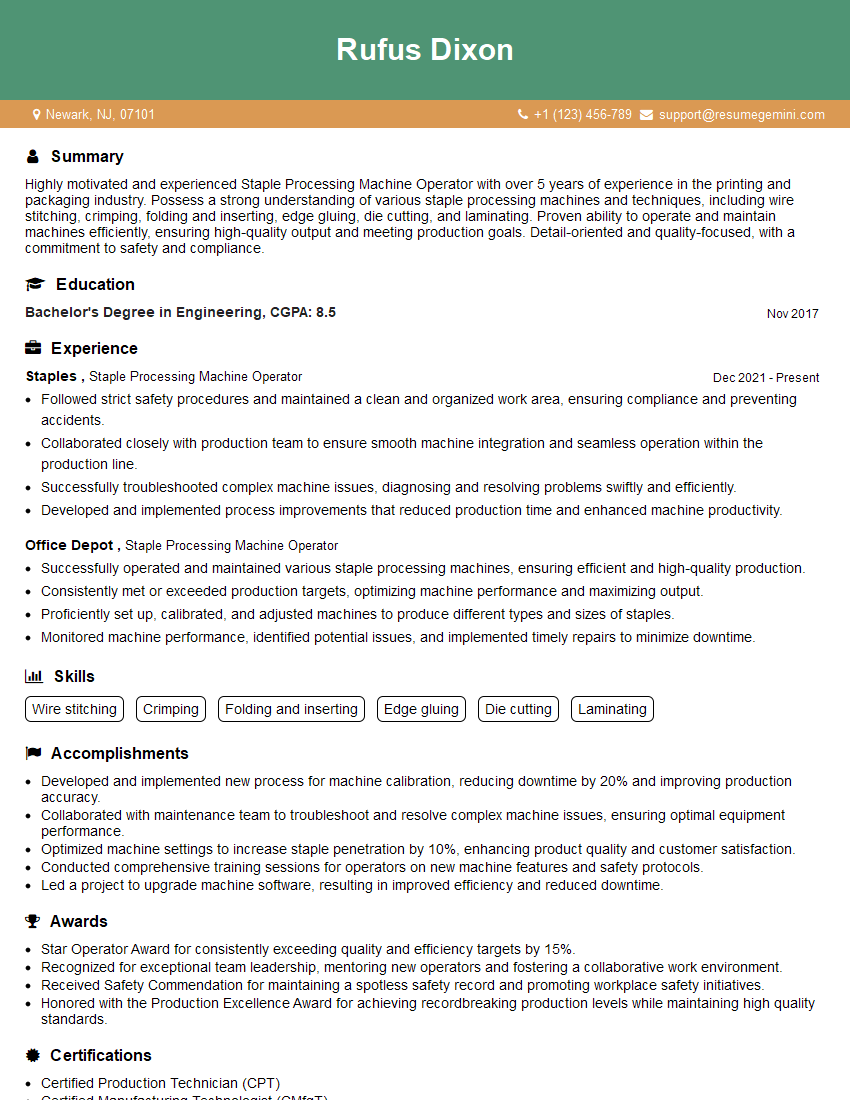

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Staple Processing Machine Operator

1. Describe the key responsibilities of a Staple Processing Machine Operator?

- Operate staple processing machine to produce staples.

- Maintain and repair staple processing machine.

- Inspect and test staples to ensure quality.

- Safe operation of the machine and follow safety guidelines.

2. Explain the process of setting up and operating a Staple Processing Machine?

Setup

- Load the wire coil onto the machine.

- Adjust the machine settings for the desired staple size and shape.

- Thread the wire through the dies.

Operation

- Start the machine and monitor its operation.

- Make adjustments to the machine settings as needed.

- Unload the finished staples.

3. How do you ensure the quality of staples produced by the machine?

- Inspect the staples for defects, such as burrs, bends, or incorrect size.

- Test the staples to ensure they meet the required specifications.

- Calibrate the machine regularly to ensure it is producing staples to the correct specifications.

4. Describe the maintenance procedures for a Staple Processing Machine?

- Clean the machine regularly to remove dust and debris.

- Lubricate the machine as per the manufacturer’s instructions.

- Inspect the machine for wear and tear, and replace any worn or damaged parts.

- Calibrate the machine regularly to ensure it is producing staples to the correct specifications.

5. What are the safety precautions that must be taken when operating a Staple Processing Machine?

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Never operate the machine with the guards removed.

- Keep hands and loose clothing away from the moving parts of the machine.

- Never attempt to clear a jam in the machine while it is running.

- Follow all lockout/tagout procedures before performing any maintenance on the machine.

6. What is the difference between a high-speed and a low-speed Staple Processing Machine?

- High-speed machines: Produce staples at a higher rate of speed, typically 300-500 staples per minute.

- Low-speed machines: Produce staples at a slower rate of speed, typically 50-100 staples per minute.

- Advantages of high-speed machines: Higher production output, suitable for large-scale operations.

- Advantages of low-speed machines: More precise, suitable for small-scale operations or specialty staples.

7. Explain how to troubleshoot common problems with a Staple Processing Machine?

- Problem: Machine is not producing staples.

- Possible causes: Wire coil not loaded properly, dies not aligned, machine not calibrated.

- Problem: Staples are not the correct size or shape.

- Possible causes: Dies worn or damaged, machine not calibrated, wire coil not the correct size.

- Problem: Staples are jamming in the machine.

- Possible causes: Machine not cleaned regularly, dies worn or damaged, wire coil not the correct size.

8. Describe your experience with using Statistical Process Control (SPC) to improve the quality of staple production?

- Monitored key quality characteristics of staples, such as size, shape, and strength.

- Collected and analyzed data using SPC charts to identify trends and variations in the process.

- Implemented process improvements to reduce variation and improve quality, such as adjusting machine settings or replacing worn parts.

9. How do you stay up-to-date on the latest advancements in Staple Processing Machine technology?

- Attend industry conferences and trade shows.

- Read industry publications and technical journals.

- Participate in online forums and discussion groups.

- Consult with equipment manufacturers and suppliers.

10. What are your career goals and how do you see yourself growing within the Staple Processing Machine industry?

- To advance in my career as a Staple Processing Machine Operator and become a Lead Operator or Supervisor.

- To learn more about the latest advancements in Staple Processing Machine technology and apply them to my work.

- To contribute to the improvement of staple production processes and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Staple Processing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Staple Processing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Staple Processing Machine Operators are responsible for operating machines that process and prepare raw materials into staples. These machines remove impurities, sort and grade the staples, and package them for sale. The primary goal of this role is to ensure that the machines operate efficiently and produce high-quality staples.

1. Machine Operation

Operate staple processing machines according to established procedures.

- Monitor machine performance and make necessary adjustments to ensure optimal operation.

- Calibrate and maintain machines to meet specifications.

2. Material Handling

Load and unload raw materials, finished products, and waste materials from machines.

- Inspect raw materials for defects and remove impurities.

- Sort and grade staples based on size, quality, and other criteria.

- Package staples in containers and label them according to specifications.

3. Quality Control

Monitor the quality of staples produced by the machines.

- Conduct visual inspections to identify defects and contaminants.

- Take corrective actions to address quality issues.

- Maintain records of quality control checks.

4. Maintenance and Repair

Perform routine maintenance and minor repairs on staple processing machines.

- Clean and lubricate machines.

- Identify and replace worn or damaged parts.

- Troubleshoot and resolve machine malfunctions.

Interview Tips

Preparing for an interview for a Staple Processing Machine Operator position requires a combination of research, practice, and self-reflection.

1. Research the Company and Industry

Gain insights into the company’s history, products, and market position.

- Check the company’s website, social media pages, and industry news.

- Learn about the specific industry trends and technologies relevant to staple processing.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses.

- Example Outline:

- Tell me about your experience operating staple processing machines.

- Describe a situation where you identified and resolved a machine malfunction.

- How do you ensure the quality of staples produced by the machines?

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that align with the job requirements.

- Quantify your accomplishments whenever possible using specific metrics and data.

- Use action verbs to describe your responsibilities and achievements.

4. Demonstrate a Strong Work Ethic and Attention to Detail

Convey your commitment to quality and efficiency.

- Provide examples of your dedication to maintaining a clean and organized work environment.

- Explain how you prioritize tasks and manage your time effectively.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Staple Processing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!