Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Starch Factory Laborer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

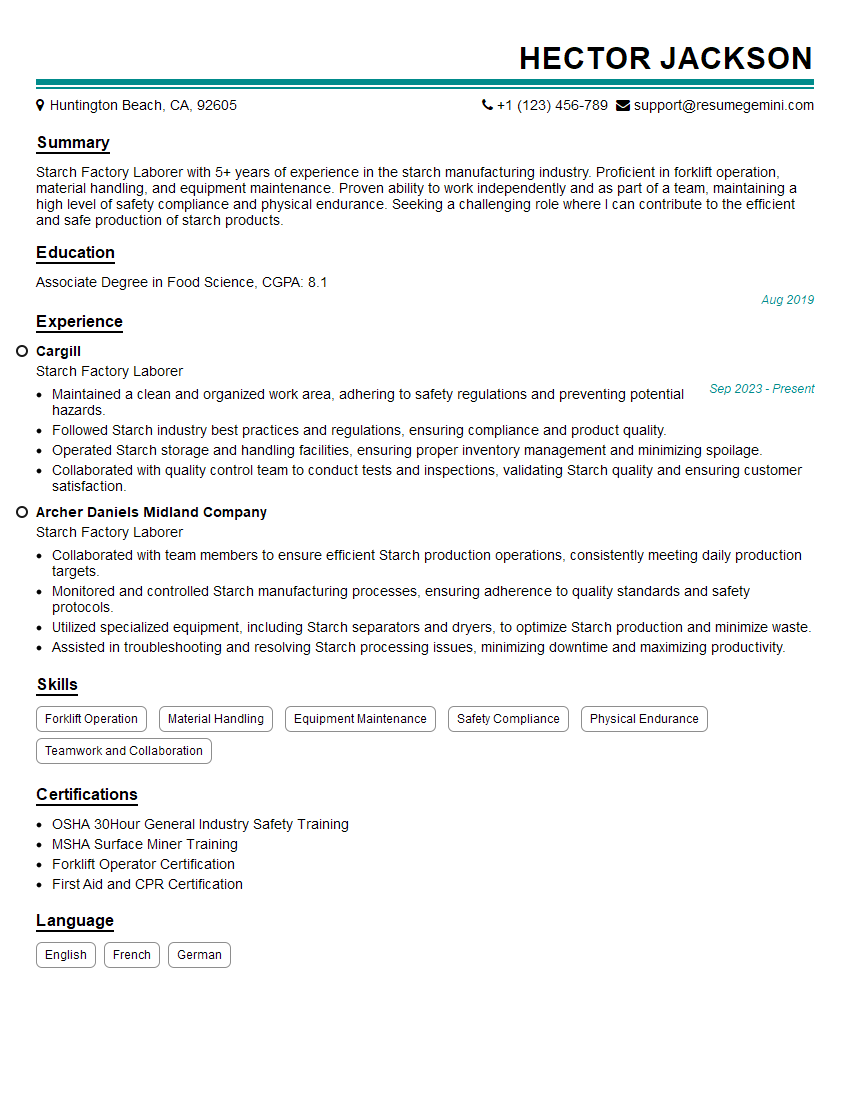

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Starch Factory Laborer

1. What are the main types of starch and their uses?

There are two main types of starch: amylose and amylopectin.

- Amylose is a linear chain of glucose molecules, while amylopectin is a branched chain of glucose molecules.

- Amylose is used in the production of paper, textiles, and adhesives, while amylopectin is used in the production of food and beverages.

2. What are the different stages of starch production?

Raw material preparation

- The first stage of starch production is raw material preparation, which involves cleaning and grinding the raw materials (such as corn, wheat, or potatoes) to break them down into smaller pieces.

Slurry preparation

- The ground raw materials are then mixed with water to form a slurry, which is then heated to gelatinize the starch granules.

Starch separation

- The gelatinized slurry is then centrifuged to separate the starch from the other components of the slurry.

Starch drying

- The separated starch is then dried to remove the moisture content and produce a dry starch powder.

3. What are the safety precautions that must be taken when working in a starch factory?

There are a number of safety precautions that must be taken when working in a starch factory, including:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat.

- Being aware of the location of fire extinguishers and other emergency equipment.

- Following all safety procedures and guidelines.

- Reporting any unsafe conditions or practices to a supervisor.

4. What are the maintenance tasks that are typically performed in a starch factory?

The maintenance tasks that are typically performed in a starch factory include:

- Inspecting and cleaning equipment.

- Lubricating moving parts.

- Adjusting and calibrating equipment.

- Replacing worn or damaged parts.

- Troubleshooting and repairing equipment.

5. What are the quality control procedures that are followed in a starch factory?

The quality control procedures that are followed in a starch factory include:

- Testing the raw materials to ensure they meet specifications.

- Monitoring the production process to ensure that the starch is produced according to specifications.

- Testing the finished starch product to ensure it meets specifications.

6. What are the environmental regulations that apply to starch factories?

The environmental regulations that apply to starch factories include:

- The Clean Air Act.

- The Clean Water Act.

- The Resource Conservation and Recovery Act.

7. What are the physical properties of starch?

The physical properties of starch include:

- It is a white, odorless, tasteless powder.

- It is insoluble in water.

- It swells when heated in water to form a gelatinous paste.

8. What are the chemical properties of starch?

The chemical properties of starch include:

- It is a polysaccharide, composed of glucose molecules.

- It is hydrolyzed by acids and enzymes to produce glucose.

- It reacts with iodine to form a blue-black complex.

9. What are the applications of starch?

Starch has a wide range of applications, including:

- In the food industry, it is used as a thickener, stabilizer, and gelling agent.

- In the paper industry, it is used as a binder and coating agent.

- In the textile industry, it is used as a sizing agent.

- In the pharmaceutical industry, it is used as a filler and binder.

10. What are the challenges and opportunities facing the starch industry?

The starch industry faces a number of challenges, including:

- The rising cost of raw materials.

- The increasing demand for starch from emerging markets.

- The development of new starch-based products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Starch Factory Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Starch Factory Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Starch Factory Laborers play a pivotal role in the production process of starch, an essential ingredient in various industries. Their primary responsibilities include:

1. Starch Production

Operate and maintain starch production equipment, ensuring efficient conversion of raw materials into starch.

- Load raw materials (e.g., corn, wheat) into processing tanks.

- Monitor and adjust temperature, pressure, and other process parameters to optimize starch yield.

- Collect and process starch slurry, separating it from impurities.

2. Equipment Maintenance and Cleaning

Maintain and clean production equipment to ensure optimal performance and prevent breakdowns.

- Lubricate, clean, and inspect machinery regularly.

- Report equipment malfunctions and assist in repairs.

- Maintain a clean and organized work area.

3. Material Handling

Move and handle heavy materials, such as starch and raw materials, safely and efficiently.

- Load and unload trucks, trailers, and conveyors.

- Operate forklifts or other material handling equipment.

- Follow safety procedures when handling heavy objects.

4. Quality Control

Monitor and maintain product quality standards throughout the production process.

- Collect samples of starch for quality testing.

- Follow quality control procedures and report any deviations.

- Assist in troubleshooting and resolving quality issues.

Interview Tips

Preparing for a Starch Factory Laborer interview is crucial to making a strong impression on the hiring manager. Here are some interview preparation tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the starch factory, its products, and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the position.

- Visit the company website and social media pages.

- Read industry news and articles to gain insights into the starch industry.

- Review the job description carefully to identify the key requirements and responsibilities.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your responses. This will help you feel more confident and articulate your skills and experience effectively.

- Tell me about yourself and your experience in the starch industry.

- Describe a time when you handled a challenging situation in a previous role.

- How do you ensure product quality and maintain safety standards in a manufacturing environment?

3. Highlight Relevant Skills and Experience

Focus on highlighting skills and experience that are relevant to the Starch Factory Laborer position. Quantify your accomplishments whenever possible to demonstrate your impact.

- Emphasize your ability to operate and maintain starch production equipment.

- Provide examples of your experience in material handling and ensuring product quality.

- Share your knowledge of safety procedures and adherence to industry standards.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows respect for the company and the interviewer.

- Choose clean and pressed business attire.

- Plan your route and allow ample time to arrive at the interview location without being late.

- Be polite and respectful to everyone you encounter, including the receptionist and other employees.

5. Follow Up and Thank the Interviewer

After the interview, promptly follow up with a thank-you email to the interviewer. This is an opportunity to reiterate your interest in the position and thank them for their time.

- Send your thank-you note within 24 hours of the interview.

- Express your gratitude for the opportunity to interview.

- Briefly reiterate your qualifications and why you are a suitable candidate for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Starch Factory Laborer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!