Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Starch Treating Assistant interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Starch Treating Assistant so you can tailor your answers to impress potential employers.

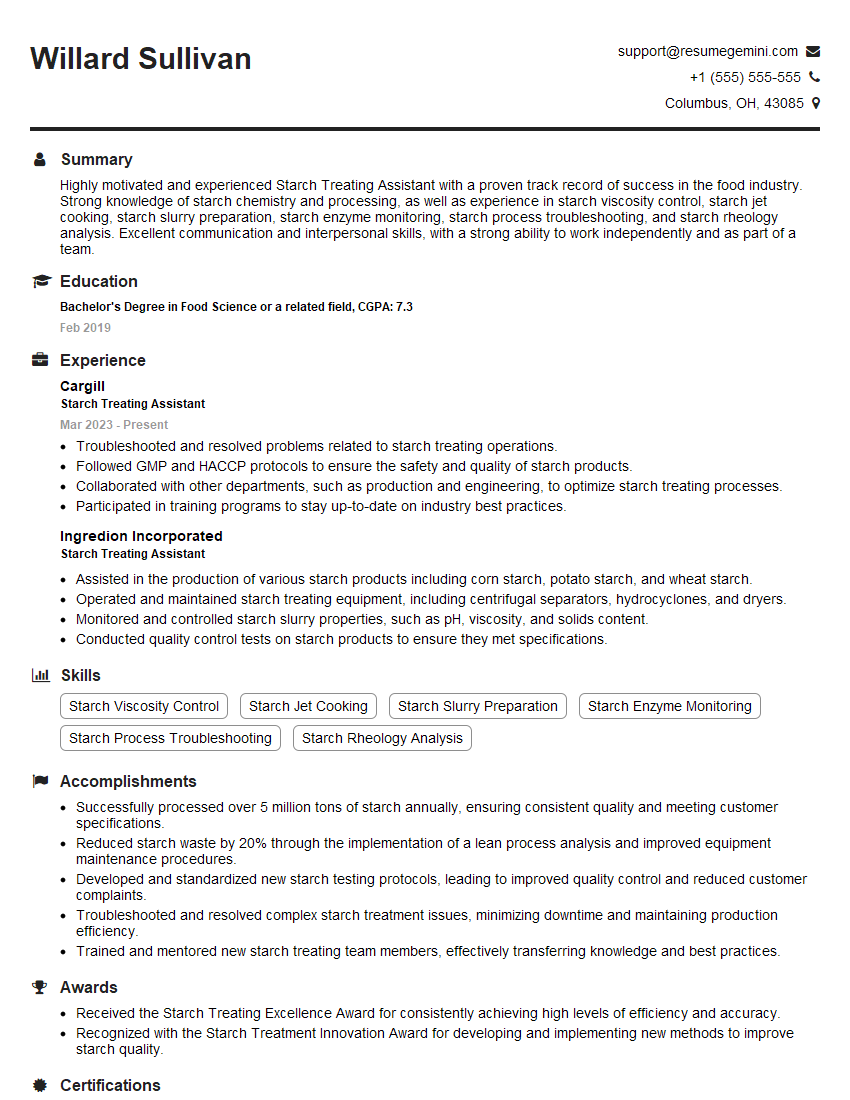

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Starch Treating Assistant

1. Describe the process of starch treating?

- The starch treating process involves preparing a starch solution and applying it to the fabric.

- The starch solution is made by mixing starch with water and heating it until the starch granules swell and burst.

- The starch solution is then applied to the fabric using a variety of methods, such as padding, spraying, or dipping.

- The starch treatment helps to stiffen the fabric and give it a smooth, glossy finish.

2. What are the different types of starch used for treating fabrics and their properties?

Native Starch

- Derived from plants like corn, wheat, and potato

- Forms a strong film on the fabric

- Provides high stiffness and crispness

Modified Starch

- Chemically treated to alter its properties

- Offers improved adhesion, flexibility, and drape

- Used in applications where softness and handle are important

3. How do you control the stiffness of the fabric after starch treatment?

- The stiffness of the fabric after starch treatment can be controlled by the concentration of the starch solution.

- A higher concentration of starch will result in a stiffer fabric.

- The temperature of the starch solution can also affect the stiffness of the fabric.

- A higher temperature will result in a less stiff fabric.

- The application method can also affect the stiffness of the fabric.

- Padding will result in a stiffer fabric than spraying or dipping.

4. How do you troubleshoot common problems that may occur during starch treating?

- If the fabric is too stiff, the starch solution may be too concentrated.

- If the fabric is not stiff enough, the starch solution may be too dilute.

- If the fabric has a rough or uneven finish, the starch solution may not have been applied evenly.

- If the fabric has a yellow or brown tinge, the starch may have been scorched during the heating process.

- If the fabric has a musty or sour odor, the starch may have been contaminated with bacteria.

5. What are the safety precautions that should be taken when working with starch?

- Starch dust can be irritating to the respiratory system, so it is important to wear a dust mask when working with starch.

- Starch can also be slippery, so it is important to wear gloves and safety glasses when working with starch solutions.

- Starch can be a fire hazard, so it is important to keep starch away from heat and open flames.

6. How do you maintain and calibrate the equipment used in starch treating?

- The equipment used in starch treating should be maintained and calibrated regularly to ensure that it is functioning properly.

- The frequency of maintenance and calibration will vary depending on the type of equipment.

- It is important to follow the manufacturer’s instructions for maintenance and calibration.

7. How do you ensure the quality of the starch-treated fabrics?

- The quality of the starch-treated fabrics can be ensured by testing the fabrics for stiffness, smoothness, and color.

- The fabrics should also be inspected for any defects, such as wrinkles or tears.

- It is important to keep records of the test results and any defects that are found.

8. What are the environmental considerations that should be taken into account when working with starch?

- Starch is a biodegradable material, but it can still have a negative impact on the environment if it is not disposed of properly.

- Starch can contribute to water pollution if it is released into waterways.

- It is important to dispose of starch in accordance with local regulations.

9. How do you stay up-to-date on the latest developments in starch treating technology?

- There are a number of ways to stay up-to-date on the latest developments in starch treating technology.

- One way is to attend industry conferences and trade shows.

- Another way is to read industry publications.

- It is also important to network with other professionals in the field.

10. What are your career goals and how do you see this role contributing to your professional development?

- My career goal is to become a Plant Manager in the textile industry.

- I believe that this role will contribute to my professional development by providing me with the opportunity to learn about the starch treating process and to gain experience in managing a team of employees.

- I am confident that I can make a significant contribution to your company and I am eager to learn more about this opportunity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Starch Treating Assistant.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Starch Treating Assistant‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Starch Treating Assistant is the backbone of a manufacturing team, working behind the scenes to ensure the smooth and efficient production of starch-based products.

1. Monitoring and Maintaining Equipment

The day-to-day operations of a Starch Treating Assistant revolve around closely monitoring the equipment used in the starch treatment process. This includes checking for any potential issues or malfunctions, as well as ensuring that all equipment is properly calibrated and maintained to meet production standards. By proactively addressing maintenance needs, they help prevent costly breakdowns and production delays.

- Conduct regular inspections of equipment, including mixers, pumps, and conveyors.

- Identify and address minor issues before they escalate into major problems.

2. Managing Starch Treatment Process

Starch Treating Assistants play a crucial role in managing the starch treatment process, which involves preparing and applying starch solutions to various products. They are responsible for ensuring the correct dosage and application of starch, as well as monitoring the progress of the treatment to achieve the desired results. This requires a deep understanding of the starch treatment process and the ability to make adjustments based on the specific requirements of each product.

- Prepare starch solutions according to specified formulas.

- Ensure that starch is applied evenly and consistently to the products.

3. Ensuring Product Quality

The primary goal of a Starch Treating Assistant is to ensure the quality of starch-treated products. They conduct regular quality checks to assess the effectiveness of the starch treatment and identify any deviations from the desired specifications. This attention to detail helps maintain consistent product quality and meet customer expectations.

- Perform quality checks on treated products to ensure they meet specifications.

- Identify and resolve any quality issues that arise during the treatment process.

4. Maintaining a Safe and Clean Work Environment

A Starch Treating Assistant is responsible for maintaining a safe and clean work environment to prevent accidents and ensure the well-being of colleagues. This includes adhering to safety protocols, wearing appropriate protective gear, and keeping the work area organized and free from hazards. They also play a role in waste management, ensuring that starch waste is disposed of properly and in compliance with environmental regulations.

- Follow established safety protocols and procedures.

- Dispose of starch waste in a safe and environmentally responsible manner.

Interview Tips

To ace your interview for a Starch Treating Assistant position, it’s essential to prepare thoroughly and demonstrate your understanding of the role’s responsibilities and the industry. Here are some tips to help you make a strong impression:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific Starch Treating Assistant position. This will give you a good understanding of their products, processes, and company culture. Use this knowledge to tailor your answers to the interviewer’s questions and show that you’re genuinely interested in the opportunity.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest developments.

2. Highlight Your Relevant Experience and Skills

When discussing your experience and skills during the interview, focus on those that are most relevant to the Starch Treating Assistant role. For instance, emphasize your experience in operating and maintaining manufacturing equipment, your understanding of starch treatment processes, and your commitment to quality control. If you have any experience working in a food manufacturing environment, be sure to highlight that as well.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Use specific examples to illustrate your skills and abilities.

3. Prepare for Common Interview Questions

There are certain interview questions that are commonly asked for Starch Treating Assistant positions. Prepare for these questions by practicing your answers ahead of time. Some common questions include:

- “Tell me about your experience in the starch manufacturing industry.”

- “What are the key steps involved in the starch treatment process?”

- “How do you ensure the quality of starch-treated products?”

- “What are your strengths and weaknesses as a Starch Treating Assistant?”

4. Ask Thoughtful Questions

At the end of the interview, you’ll likely have the opportunity to ask the interviewer questions. This is your chance to show that you’re engaged and interested in the position. Prepare a few thoughtful questions related to the role, the company, or the industry. This will demonstrate your enthusiasm for the opportunity and your desire to learn more.

- Ask about the company’s growth plans and future goals.

- Inquire about the company’s commitment to sustainability and environmental responsibility.

- Ask about opportunities for professional development and career advancement within the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Starch Treating Assistant interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.