Are you gearing up for an interview for a Stator Winder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Stator Winder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

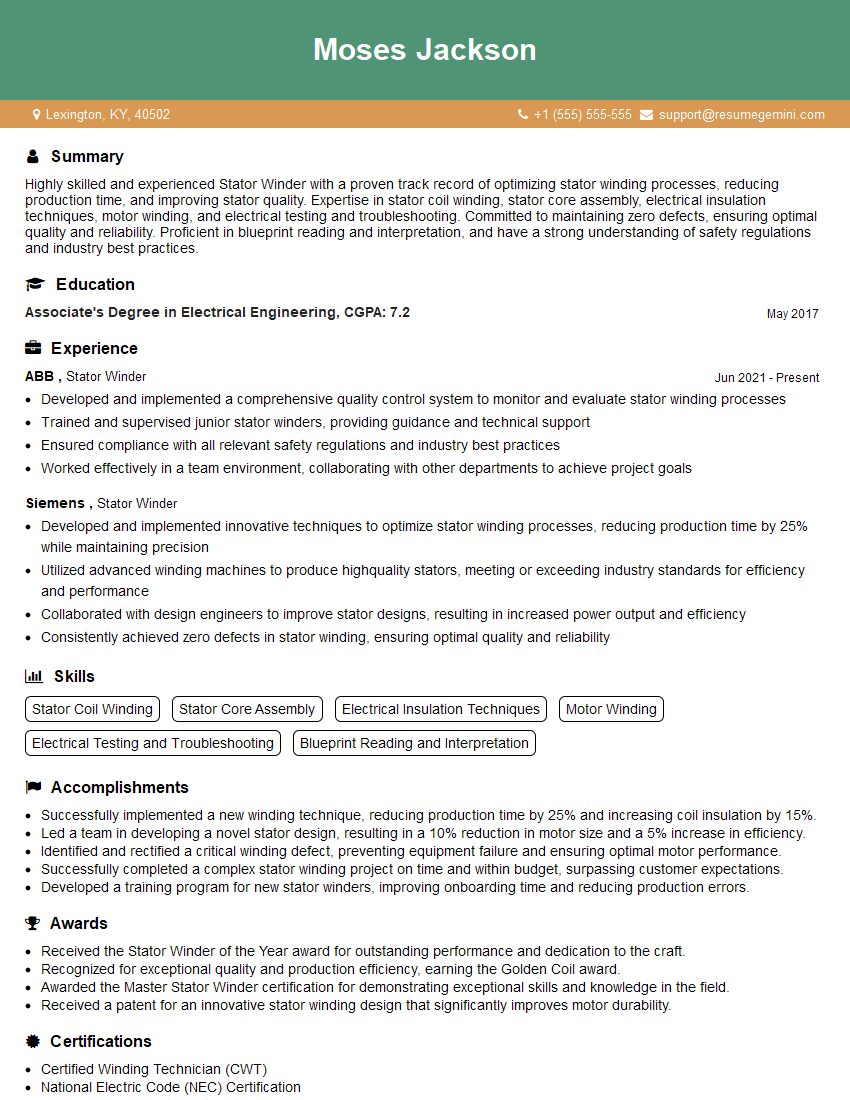

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stator Winder

1. Explain the process of stator winding in detail?

- Preparing the stator core: Removing any burrs or imperfections from the stator core.

- Inserting the stator coils: Carefully inserting pre-wound stator coils into the stator slots.

- Connecting the coils: Joining the ends of the stator coils together using soldering or other methods.

- Insulating the windings: Applying insulation materials to protect the windings from electrical shorts.

- Testing and quality control: Thoroughly testing the wound stator to ensure it meets specifications and is free from defects.

2. What are the different types of stator winding patterns?

Concentric Winding

- Coils are wound in concentric circles around the stator core.

- Suitable for low-voltage, high-current applications.

Lap Winding

- Coils are wound in a back-and-forth pattern across the stator slots.

- Produces a higher voltage output compared to concentric winding.

Wave Winding

- Similar to lap winding, but the coils are wound in a wave-like pattern.

- Used in high-voltage, low-current applications.

3. What tools and equipment are essential for stator winding?

- Coil winding machine

- Insulation materials (e.g., varnish, tape)

- Soldering iron or welding equipment

- Testing equipment (e.g., ohmmeter, insulation tester)

- Safety gear (e.g., gloves, safety glasses)

4. How do you ensure the quality of stator windings?

- Using high-quality materials and following precise winding procedures.

- Thorough testing at each stage of the winding process.

- Regular calibration of testing equipment.

- Adhering to industry standards and specifications.

- Implementing quality control measures throughout the production process.

5. What are the common faults that can occur in stator windings and how do you troubleshoot them?

- Shorted windings: Use an ohmmeter to identify shorted coils.

- Open windings: Use a continuity tester to locate open circuits.

- Ground faults: Use an insulation tester to detect insulation breakdowns.

- Loose connections: Inspect connections and tighten them as necessary.

- Overheating: Check for excessive current or poor ventilation.

6. How do you calculate the number of turns required for a stator winding?

- Determine the desired voltage output.

- Calculate the number of turns per coil using the formula: Turns = Voltage / (2 * Flux * Conductor Cross-sectional Area * Current Density)

- Multiply the number of turns per coil by the number of coils in the stator.

7. What are the safety precautions to follow when working with stator windings?

- Wear appropriate safety gear, including gloves and safety glasses.

- Ensure that the equipment is properly grounded.

- Use insulated tools and avoid touching exposed conductors.

- Do not work on live equipment.

- Follow proper lockout/tagout procedures.

8. Describe the different types of insulation materials used in stator windings?

- Enamel insulation: Thin, heat-resistant enamel coating applied to individual conductors.

- Varnish insulation: Liquid varnish that is applied to the wound stator to provide additional insulation and protection.

- Slot liners: Insulating materials placed in the stator slots to prevent direct contact between the windings and the core.

- Phase insulation: Materials used to isolate different phases of the stator winding from each other.

9. What is the importance of balancing stator windings?

- Reduces vibration and noise during motor operation.

- Ensures even distribution of magnetic forces, improving motor efficiency.

- Prevents overheating and premature failure of the stator.

- Minimizes electromagnetic interference with other components.

10. How do you keep up with advancements in stator winding technology?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with experts in the field.

- Participate in professional development programs.

- Stay informed about new materials and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stator Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stator Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stator Winders play a crucial role in manufacturing electric motors and generators. Their primary responsibility is to precisely wind coils of wire around a stator core, ensuring proper electrical connections and insulation.

1. Coil Winding

Stator Winders are responsible for winding coils of wire around the stator core according to specified design parameters. They use specialized winding machines or manual techniques to create coils with the correct number of turns, pitch, and tension.

2. Coil Insulation and Connections

To prevent electrical shorts and ensure proper operation, Stator Winders apply insulation materials between coils and make electrical connections using soldering, crimping, or other methods.

3. Quality Control and Testing

Stator Winders conduct thorough quality checks to ensure that the stator meets electrical and mechanical specifications. They test for insulation resistance, continuity, and other parameters to identify and rectify any discrepancies.

4. Troubleshooting and Maintenance

In the event of stator malfunctions, Stator Winders troubleshoot and repair the unit. They diagnose electrical faults, replace defective coils, and perform necessary maintenance tasks to ensure optimal performance.

Interview Tips

To ace the interview for a Stator Winder position, candidates should prepare thoroughly and demonstrate their skills and knowledge in the following areas:

1. Technical Skills

Candidates should be well-versed in stator winding techniques, insulation materials, and electrical testing methods. They should have a strong understanding of electrical principles and be able to interpret technical drawings.

2. Experience and Certifications

Experience in stator winding is highly valued. Candidates should highlight their previous projects and any relevant certifications they have obtained, such as those from the National Institute for Certification in Engineering Technologies (NICET).

3. Problem-Solving and Attention to Detail

Stator Winders must be able to troubleshoot electrical problems and maintain high levels of accuracy and attention to detail. Candidates should emphasize their ability to identify and resolve technical issues.

4. Communication and Teamwork

Stator Winders often work as part of a team and need to effectively communicate with supervisors, engineers, and other colleagues. They should be able to convey technical information clearly and work collaboratively to meet project deadlines.

5. Example Outline for Interview Question Responses:

- Behavioral Interview Question: Tell me about a time you faced a technical challenge while winding a stator.

- Example Outline:

- Describe the specific challenge encountered.

- Explain the steps taken to troubleshoot the issue.

- Highlight the methods used to resolve the problem.

- Emphasize the technical skills and knowledge applied.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stator Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!