Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Steam Turbine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Steam Turbine Operator so you can tailor your answers to impress potential employers.

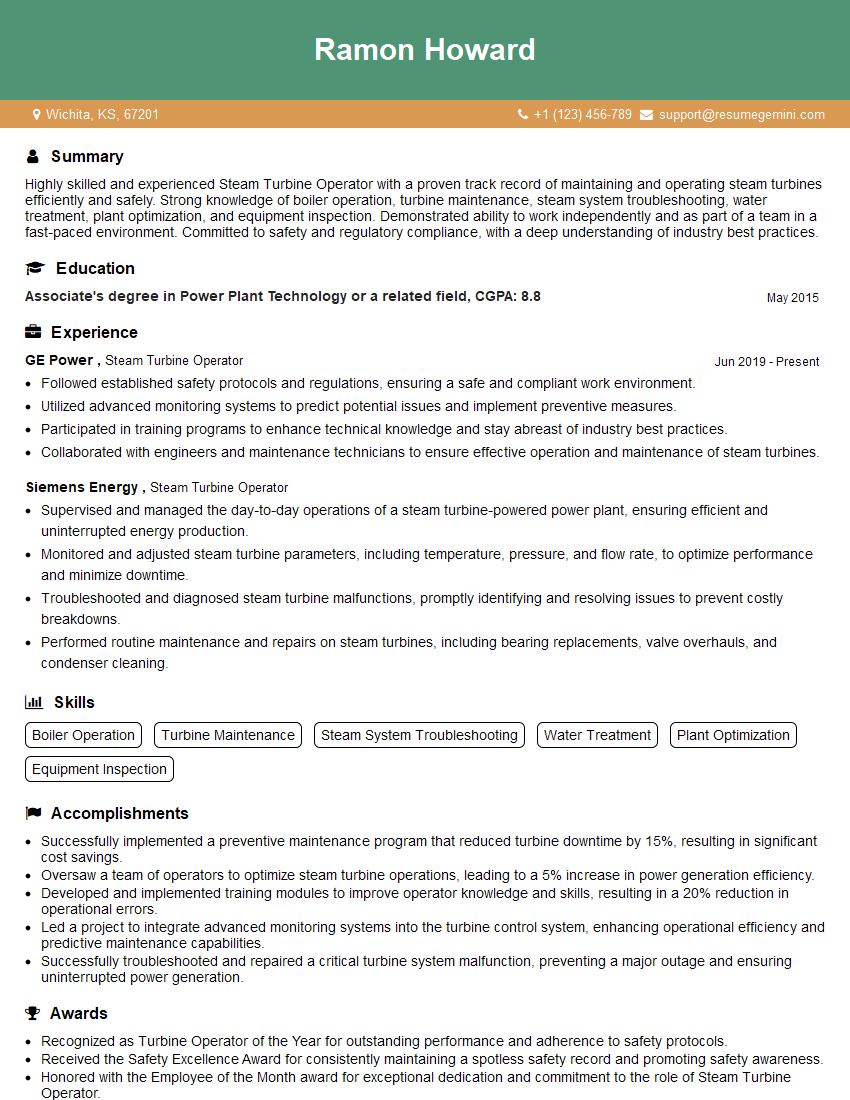

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steam Turbine Operator

1. Explain the operational principles of a steam turbine, including the flow path of steam through the turbine.

A steam turbine converts the thermal energy of steam into mechanical energy. It consists of a series of stationary blades (nozzles) and rotating blades (buckets) arranged alternately around the circumference of a cylindrical casing. Steam from the boiler enters the turbine through the admission valve and is expanded through the nozzles, which converts the pressure energy of the steam into kinetic energy. The high-velocity steam exiting the nozzles impinges on the buckets, causing them to rotate. The steam then passes through the subsequent stages of the turbine, where it undergoes further expansion and imparts more energy to the rotating blades.

2. How do you maintain the correct lubrication system for a steam turbine?

Monitoring and Inspection

- Regularly check oil levels, pressure, and temperature.

- Inspect lubrication components for wear and damage.

Oil Quality Management

- Conduct oil analysis to monitor contamination levels and oil condition.

- Change oil and filters according to the manufacturer’s recommendations.

System Maintenance

- Clean and flush lubrication lines and components to remove contaminants.

- Overhaul or replace lubrication pumps and other components as needed.

3. What are the different types of steam turbine governing systems and how do they control turbine speed?

Mechanical governor: Uses a mechanical linkage to adjust the steam flow rate to maintain turbine speed.

Hydraulic governor: Employs hydraulic pressure to control the steam flow rate and maintain turbine speed.

Electronic governor: Utilizes electronic sensors and actuators to precisely control steam flow and maintain turbine speed.

4. Describe the various methods used to protect steam turbines from damage, such as overspeed, high temperature, and vibration.

- Overspeed protection: Emergency trip systems, such as mechanical overspeed trip devices and electronic overspeed governors, shut down the turbine if it exceeds a safe operating speed.

- High-temperature protection: Thermocouples and temperature sensors monitor turbine temperatures. If excessive temperatures are detected, protective systems activate to reduce steam flow or trip the turbine offline.

- Vibration protection: Vibration sensors monitor the turbine’s vibration levels. Excessive vibration can indicate problems such as unbalance, misalignment, or bearing issues. Protection systems can trip the turbine offline if vibration levels exceed safe limits.

5. How do you troubleshoot common problems encountered with steam turbines, such as vibration, steam leakage, or bearing issues?

- Vibration: Check alignment, balance, and bearing condition. Tighten loose components and correct any misalignment.

- Steam leakage: Inspect seals and gaskets for damage or wear. Replace or repair leaking components.

- Bearing issues: Monitor bearing temperatures and listen for unusual noises. Lubricate bearings properly and replace worn or damaged bearings.

6. Describe the procedures for starting up and shutting down a steam turbine safely and efficiently.

Start-up

- Open the steam admission valve gradually.

- Increase turbine speed slowly while monitoring parameters such as temperature, pressure, and vibration.

- Bring the turbine to the desired operating speed and load.

Shut-down

- Gradually reduce the turbine load.

- Close the steam admission valve slowly.

- Monitor the turbine as it coasts to a stop, ensuring proper cooling and lubrication.

7. What are the key safety considerations when working with steam turbines?

- Wear appropriate personal protective equipment (PPE), including high-visibility clothing, safety glasses, and hearing protection.

- Be aware of the potential for high temperatures, steam leaks, and rotating machinery.

- Follow established safety protocols and procedures.

- Never work on a turbine that is running or under pressure.

8. Explain how you would optimize the performance of a steam turbine for efficiency and reliability.

- Maintain optimal steam conditions: Ensure proper steam pressure, temperature, and purity to maximize turbine efficiency.

- Regular maintenance and inspections: Conduct regular inspections, cleanings, and overhauls to maintain turbine components in good operating condition.

- Performance monitoring and analysis: Track turbine performance parameters and identify areas for improvement.

- Operator training: Ensure operators are well-trained and follow best practices for turbine operation.

9. What are the different types of steam turbine designs and their respective applications?

- Impulse turbines: Used for high-pressure, low-volume steam applications, such as small power plants and marine propulsion.

- Reaction turbines: Suitable for low-pressure, high-volume steam applications, such as large power plants and industrial processes.

- Condensing turbines: Exhaust steam into a condenser to create a vacuum, improving efficiency.

- Non-condensing turbines: Exhaust steam directly to the atmosphere, used in applications where exhaust heat can be utilized.

10. Describe the role of steam turbines in combined cycle power plants.

Steam turbines play a crucial role in combined cycle power plants, which combine gas and steam turbines to achieve high overall efficiency. The exhaust heat from the gas turbines is utilized to generate steam in a heat recovery steam generator (HRSG). This steam is then expanded through the steam turbine, producing additional power. Combined cycle power plants can achieve efficiencies of over 60%, making them one of the most efficient methods of electricity generation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steam Turbine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steam Turbine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steam Turbine Operators play a pivotal role in ensuring the smooth and efficient operation of power plants, generating electricity for communities and industries. Their responsibilities encompass a wide range of tasks, including:

1. Monitoring and Control

Operators are responsible for continuously monitoring and controlling the steam turbine and associated equipment, ensuring optimal performance and maintaining system parameters within safe operating limits.

- Observing gauges, meters, and other instruments to track turbine speed, pressure, temperature, and other critical variables.

- Adjusting valves, pumps, and other controls to regulate steam flow, pressure, and other operating conditions.

2. Maintenance and Repair

Operators perform routine maintenance and repairs to keep the steam turbine and related equipment in good working order, preventing breakdowns and ensuring reliability.

- Lubricating moving parts, inspecting components for wear or damage, and replacing or repairing as needed.

- Conducting periodic maintenance checks, such as vibration analysis, oil sampling, and leak inspections.

3. Emergency Response

In the event of emergencies or system malfunctions, operators are responsible for taking immediate action to mitigate risks and protect the equipment and personnel.

- Responding quickly to alarms and taking appropriate measures to shut down or isolate the turbine.

- Investigating and troubleshooting system failures to identify the root cause and implement corrective actions.

4. Record Keeping and Reporting

Operators maintain detailed records of turbine operation, maintenance activities, and any incidents or system irregularities.

- Documenting operating data, maintenance logs, and any deviations from standard operating procedures.

- Reporting system performance, maintenance schedules, and any potential issues to supervisors or engineers.

Interview Tips

To ace your interview for a Steam Turbine Operator position, it’s crucial to prepare thoroughly and showcase your skills and knowledge. Here are some tips to help you succeed:

1. Research the Company and Role

Familiarize yourself with the company’s history, mission, and the specific requirements of the Steam Turbine Operator role. This will help you tailor your answers and demonstrate your understanding of the position.

- Visit the company’s website to learn about their operations and values.

- Search for industry news and articles to stay up-to-date on the latest trends and technologies in steam turbine operation.

2. Highlight Your Technical Skills

Emphasize your technical proficiency in steam turbine operation, maintenance, and troubleshooting. Provide specific examples of your experience and accomplishments.

- Describe your experience in monitoring and controlling steam turbines, including the use of instrumentation and control systems.

- Discuss your involvement in maintenance and repair tasks, highlighting your ability to diagnose and resolve issues efficiently.

3. Demonstrate Your Problem-Solving Abilities

Interviewers will be interested in your ability to handle challenges and solve problems in a high-pressure environment. Share examples of how you have overcome technical difficulties or dealt with unexpected situations effectively.

- Recount a time when you quickly identified and resolved a system malfunction, preventing further damage or downtime.

- Describe how you analyzed a complex operating issue and implemented a solution that improved turbine performance.

4. Emphasize Your Communication and Teamwork Skills

Effective communication and teamwork are essential for Steam Turbine Operators. Highlight your ability to clearly convey information, collaborate with colleagues, and work in a team environment.

- Provide examples of how you have effectively communicated with supervisors, engineers, and other team members during critical situations.

- Discuss your experience in working as part of a team to achieve common goals and maintain a safe and efficient work environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Steam Turbine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Steam Turbine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.