Are you gearing up for a career in Steel Checker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Steel Checker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

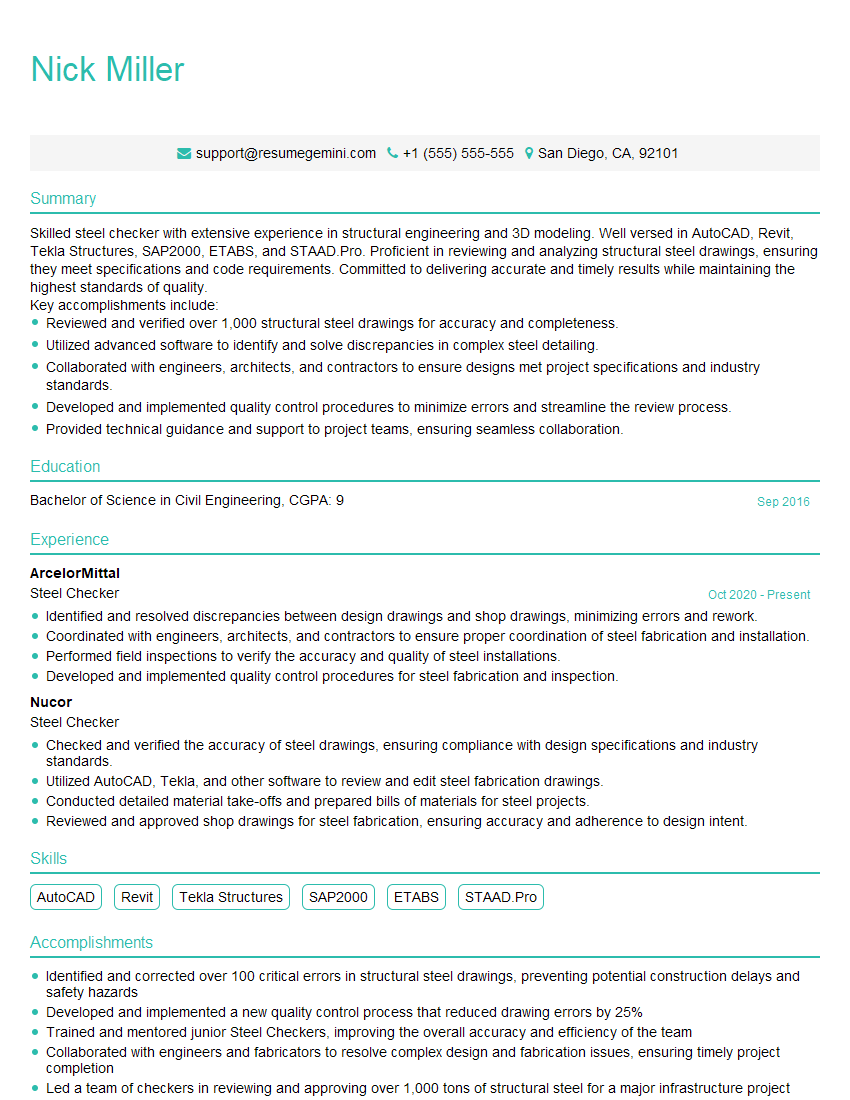

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Checker

1. Describe the role and responsibilities of a Steel Checker.

The primary responsibility of a Steel Checker is to verify and inspect steel components and structures to ensure they meet required standards, specifications, and quality requirements. The role involves analyzing drawings, conducting measurements, and assessing materials to evaluate their compliance and conformity with design specifications.

- Inspect steel components for dimensional accuracy, shape, and size

- Check material grade, heat treatment, surface finish, and other properties

- Verify compliance with engineering drawings and industry standards

- Identify and report any irregularities, defects, or deviations

- Maintain accurate records of inspections and provide written reports

2. What are the essential skills and qualifications required for a Steel Checker?

Technical Skills

- Thorough knowledge of steel metallurgy and material properties

- Understanding of structural steel design principles and fabrication processes

- Proficiency in inspection techniques and equipment, such as calipers, gauges, and measuring devices

- Knowledge of relevant industry codes, standards, and regulations

Soft Skills

- Strong attention to detail and analytical abilities

- Excellent communication and reporting skills

- Ability to work independently and as part of a team

- Problem-solving and decision-making capabilities

3. Explain the process of conducting a steel inspection.

The process of steel inspection typically follows a structured approach:

- Review Drawings and Specifications: Study the design drawings and technical specifications to understand the intended design, materials, and dimensions.

- Visual Inspection: Conduct a thorough visual examination of the steel components, checking for visible defects, damage, or irregularities.

- Dimensional Verification: Use precision measuring tools, such as calipers, micrometers, and gauges, to verify the dimensions and geometry of the components against the specified tolerances.

- Material Testing: Perform or oversee material testing, such as hardness tests, tensile tests, or chemical analysis, to assess the material properties and ensure compliance with specifications.

- Non-Destructive Testing (NDT): Employ NDT methods, such as ultrasonic testing or magnetic particle inspection, to detect hidden defects or irregularities that may not be visible during visual inspection.

- Documentation and Reporting: Record all inspection findings, including any deviations or non-conformances, in a detailed report. The report should include clear documentation of the inspection methods used and the results obtained.

4. Describe the different types of steel defects and their potential causes.

- Surface Defects: Scratches, pits, cracks, or inclusions on the surface, which can affect the structural integrity and appearance.

- Dimensional Errors: Deviations in size, shape, or geometry, which can compromise the fit and function of the components.

- Material Defects: Inclusions, voids, laminations, or impurities within the steel, which can affect its strength and durability.

- Fabrication Defects: Errors or deficiencies introduced during the manufacturing process, such as welding imperfections, heat treatment issues, or improper assembly.

5. How do you ensure the accuracy and reliability of your inspections?

- Use calibrated and certified inspection equipment regularly.

- Follow established inspection procedures and checklists.

- Conduct independent cross-checks and have inspections verified by a supervisor.

- Stay up-to-date on industry best practices and advancements in inspection technology.

- Maintain a meticulous record of all inspections, including any deviations or non-conformances.

6. What software and tools do you use for steel inspection and documentation?

- Inspection Management Software: To manage inspection schedules, track inspection results, and generate reports.

- 3D Modeling and Inspection Tools: For analyzing complex designs and comparing measured data against digital models.

- Data Collection and Analysis Tools: To capture inspection data, perform statistical analysis, and identify trends.

- Document Management Systems: For organizing and storing inspection records, drawings, and other relevant documentation.

7. How do you handle situations where you identify non-compliant materials or components?

- Notify the responsible parties immediately and provide a clear explanation of the non-conformances.

- Isolate the affected materials or components to prevent their use or installation.

- Document the non-conformances thoroughly, including the location, nature, and severity of the issues.

- Work with the relevant teams to determine the root cause of the non-conformances and develop corrective actions.

- Monitor the implementation of corrective actions to ensure that the non-conformances are effectively addressed.

8. How do you stay updated on the latest advancements in steel inspection techniques and industry standards?

- Attend industry conferences and seminars.

- Read technical journals and publications.

- Participate in professional organizations and networking events.

- Obtain industry certifications and training.

- Collaborate with experts and researchers in the field.

9. How do you prioritize your workload and manage multiple inspections simultaneously?

- Develop a clear inspection schedule based on project deadlines and resource availability.

- Prioritize inspections based on risk and potential impact on the project.

- Delegate tasks to team members when necessary, ensuring proper training and oversight.

- Use inspection management software to track progress and identify potential bottlenecks.

- Communicate regularly with stakeholders to keep them informed of inspection status and any potential delays.

10. Describe a challenging inspection project you have worked on and how you overcame the obstacles.

(Provide a specific example from your professional experience, highlighting your problem-solving abilities and technical expertise.)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

1. Document Review

Steel Checkers meticulously examine engineering drawings, fabrication details, and other relevant documents to ensure accuracy and compliance with specifications and codes.

- Analyze load calculations and structural designs to verify their correctness.

- Check for errors, omissions, and inconsistencies in the documentation.

2. Quality Control

They monitor the fabrication process to ensure the quality and accuracy of steel components.

- Inspect raw materials and finished products for defects and compliance with specifications.

- Witness welding, bolting, and other fabrication procedures to ensure they are executed according to standards.

3. Code Compliance

Steel Checkers ensure that steel structures meet all applicable building and safety codes.

- Familiarize themselves with relevant codes and regulations.

- Verify that designs and fabrications conform to these codes to ensure safety and structural integrity.

4. Coordination and Collaboration

They work closely with engineers, architects, and contractors throughout the construction process.

- Resolve discrepancies and coordinate design changes to maintain project timelines.

- Provide feedback and recommendations to improve the efficiency and safety of steel structures.

1. Preparation

- Thoroughly research the company and the Steel Checker position.

- Review relevant codes and regulations, such as the AISC Steel Construction Manual and AWS Welding Standards.

- Prepare examples of your experience in document review, quality control, code compliance, and coordination.

2. Professionalism and Communication

- Dress professionally and arrive on time for the interview.

- Be articulate, clear, and confident in your responses.

- Ask thoughtful questions to demonstrate your interest and engagement.

3. Highlight Relevant Skills

- Emphasize your proficiency in reviewing engineering drawings and fabrication details.

- Showcase your knowledge of steel construction methods and quality control procedures.

- Demonstrate your understanding of relevant codes and regulations.

4. Teamwork and Collaboration

- Explain your ability to work effectively with engineers, architects, and contractors.

- Provide examples of how you have collaborated to resolve issues and achieve project goals.

- Discuss your commitment to maintaining positive and productive relationships.

Next Step:

Now that you’re armed with the knowledge of Steel Checker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Steel Checker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini