Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Steel Construction Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

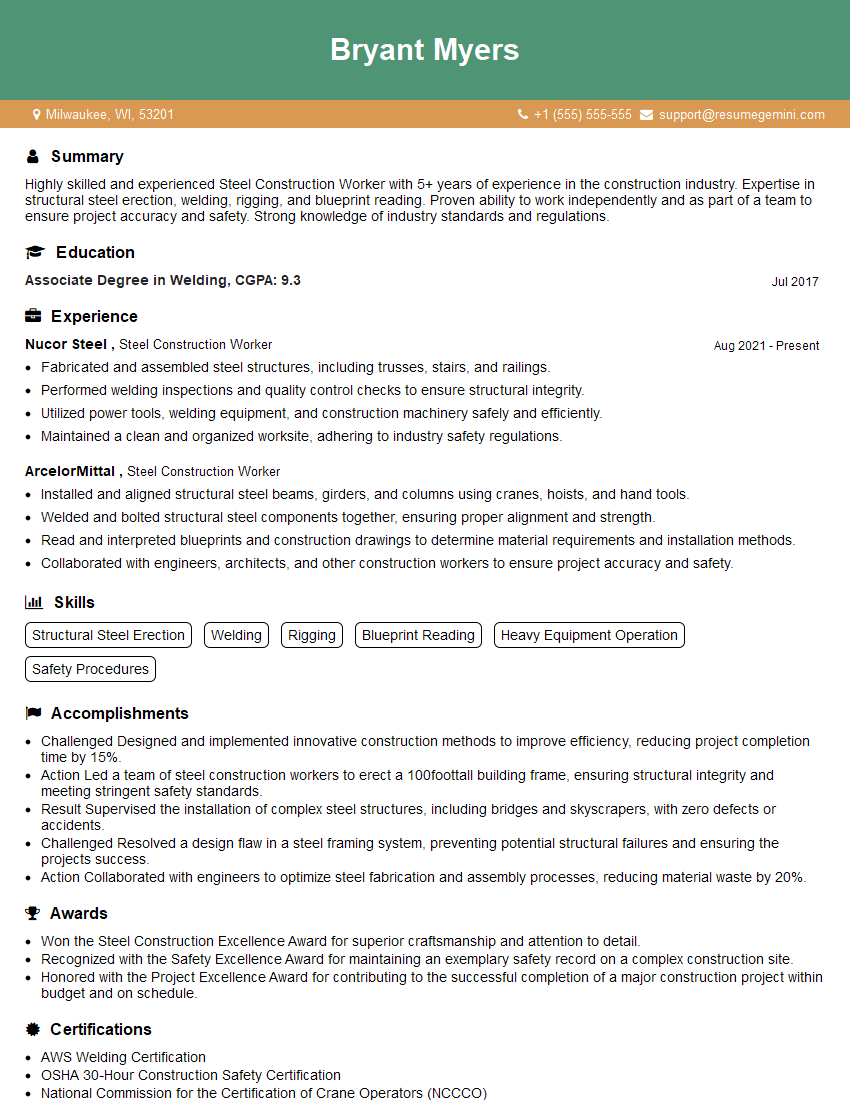

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Construction Worker

1. Describe the process of welding steel beams using the shielded metal arc welding (SMAW) technique?

- Prepare the welding area by cleaning and grinding the surfaces to be joined.

- Select the appropriate welding rod and flux for the type of steel being welded.

- Set up the welding machine according to the recommended settings for the welding rod and material thickness.

- Strike an arc and hold the welding rod at a 45-degree angle to the workpiece.

- Move the welding rod along the joint, adding filler metal as needed to create a strong weld.

- Allow the weld to cool and inspect it for any defects.

2. How do you ensure the safety of workers when working with heavy steel beams?

Proper Equipment

- Use proper personal protective equipment (PPE), including hard hats, safety glasses, gloves, and steel-toed boots.

- Ensure that all equipment, such as cranes and lifts, are in good working order and have been inspected.

Safe Work Practices

- Follow designated work procedures and lift plans to ensure safe handling of beams.

- Use proper lifting techniques to prevent strains or injuries.

- Secure beams properly to prevent them from falling or shifting.

3. Explain the techniques for cutting steel beams using a plasma cutter?

- Mark the cutting line on the steel beam.

- Set up the plasma cutter and adjust the settings for the thickness of the steel.

- Hold the plasma cutter perpendicular to the steel surface and start the cutting process.

- Move the plasma cutter along the cutting line at a steady pace.

- Monitor the cut quality and adjust the settings or cutting speed as needed.

4. Describe the different types of steel bolts used in steel construction and their applications?

- High-strength bolts: Used in critical structural connections where high strength is required, such as in bridges and skyscrapers.

- Standard bolts: General-purpose bolts used in non-critical connections, such as framing and connections between non-structural elements.

- Carriage bolts: Have a rounded head and a square neck, and are used to fasten wood or metal to concrete or masonry.

- Flange bolts: Have a large head with a beveled edge, and are used to connect flanges of beams or columns.

5. Explain the importance of proper alignment and leveling of steel beams during construction?

- Structural integrity: Improper alignment or leveling can compromise the strength and stability of the structure.

- Load distribution: Correct alignment ensures that loads are distributed evenly throughout the structure.

- Aesthetics: Poor alignment or leveling can affect the overall appearance of the building.

- Construction efficiency: Correct alignment allows for easier installation of other components, such as cladding and windows.

6. How do you inspect steel beams for defects and damage?

- Visual inspection: Look for cracks, dents, or other surface defects.

- Ultrasonic testing: Uses sound waves to detect internal defects.

- Magnetic particle inspection: Magnetizes the steel and uses magnetic particles to detect surface and near-surface defects.

- Dye penetrant testing: Uses a dye to penetrate surface defects and reveal them under ultraviolet light.

7. Describe the different types of steel connections used in building construction?

- Bolted connections: Use bolts to connect steel members and are typically used in non-critical applications.

- Welded connections: Use welding to fuse steel members together and are used in critical applications requiring high strength.

- Riveted connections: Use rivets to connect steel members, an older technique that is still used in some applications.

- Pinned connections: Use pins to connect steel members and allow for movement or rotation.

8. How do you handle and store steel beams safely to prevent accidents?

- Proper lifting techniques: Use cranes or hoists to lift beams, and ensure proper rigging and load distribution.

- Secure storage: Store beams in designated areas, elevated off the ground to prevent damage or tripping hazards.

- Marking and identification: Mark beams clearly with their size, weight, and any other important information.

- Regular inspections: Regularly inspect beams for any damage or defects before handling or use.

9. How do you calculate the weight of a steel beam based on its dimensions and density?

- Determine the volume of the beam by multiplying its length, width, and height.

- Multiply the volume by the density of steel, which is typically 7.85 g/cm³ or 0.283 lb/in³.

- Convert the result to the desired unit of weight, such as pounds or kilograms.

10. Describe your experience in using different types of steel construction tools and equipment?

- Welding equipment: Arc welders, MIG welders, TIG welders.

- Cutting equipment: Plasma cutters, oxy-fuel torches, angle grinders.

- Lifting equipment: Cranes, hoists, forklifts.

- Measuring and layout tools: Levels, squares, tape measures.

- Hand tools: Hammers, wrenches, pliers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Construction Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Construction Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Construction Workers play a vital role in erecting and maintaining steel structures, showcasing their skills in welding, cutting, and assembling steel components. Here are the key responsibilities of a Steel Construction Worker:

1. Steel Structure Erection

Using specialized tools, such as cranes and hoists, Steel Construction Workers lift and position steel beams, columns, and other components into place, ensuring proper alignment and stability.

2. Welding and Cutting

They are highly proficient in welding and cutting techniques, utilizing welding torches and grinders to join and shape steel components as per design specifications.

3. Structural Assembly

Workers meticulously assemble steel structures, bolting and riveting components together, and ensuring their secure and precise connection.

4. Safety Procedures

Safety is paramount. Steel Construction Workers are responsible for adhering to workplace safety protocols, using appropriate personal protective equipment, and ensuring their own safety and the safety of those around them.

Interview Tips

Preparing for a Steel Construction Worker interview demands thorough preparation to highlight your skills and make a lasting impression. Here are some crucial tips:

1. Research the Company and Industry

Familiarize yourself with the company’s background, projects, and industry trends. Demonstrate your understanding of the steel construction sector, showcasing your passion and knowledge.

2. Practice Your Responses

Anticipate common interview questions and prepare well-structured answers that highlight your expertise. Focus on providing specific examples from your previous experiences to demonstrate your abilities.

3. Showcase Your Skills and Certifications

Emphasize your proficiency in welding, cutting, and structural assembly techniques. Mention any relevant certifications or training you possess, such as the AWS certification or OSHA safety training.

4. Highlight Your Safety Consciousness

Stress the importance you place on workplace safety, describing your adherence to safety protocols and your commitment to maintaining a safe work environment.

5. Prepare Questions for the Interviewer

Show your engagement by asking insightful questions about the company, the project, and the team you would be joining. This reflects your curiosity and interest in the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Steel Construction Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!