Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Steel Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

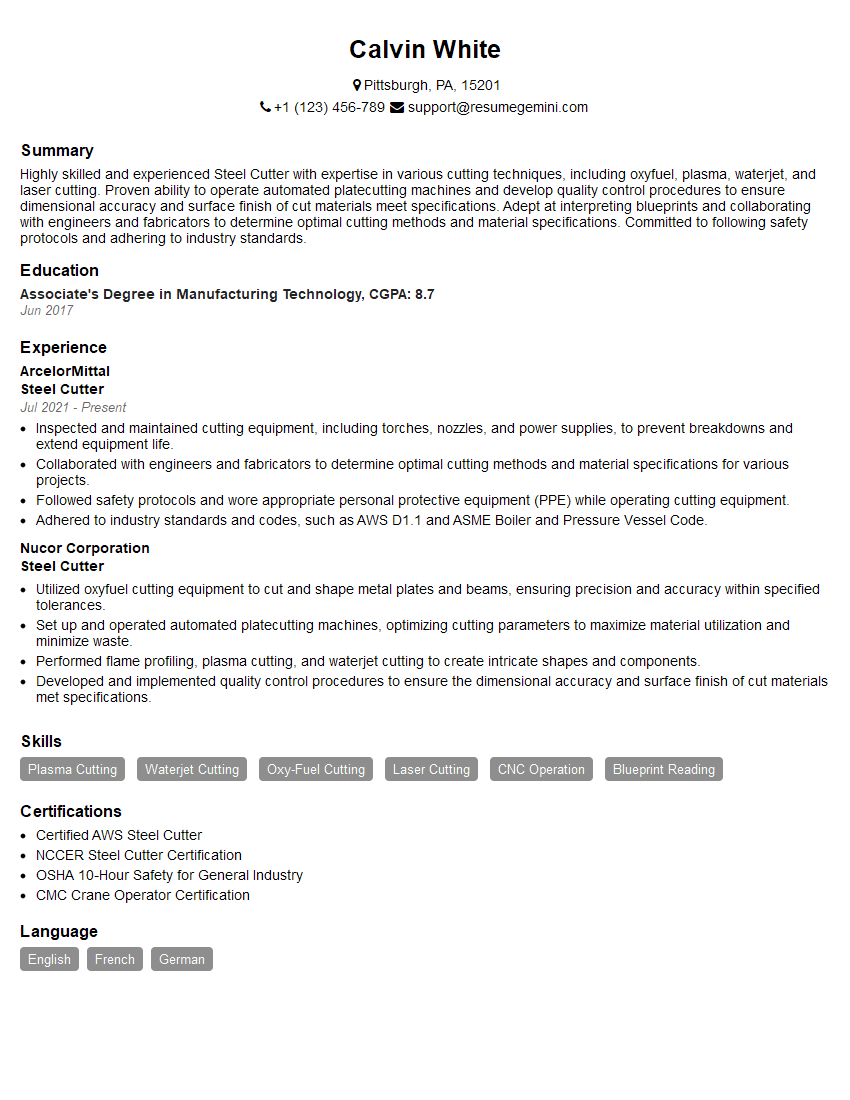

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Cutter

1. What are the key safety measures you take while operating a steel cutter?

- Wear appropriate protective gear, including safety glasses, gloves, and a hard hat.

- Inspect the equipment before use to ensure it is in good working order.

- Secure the steel to be cut with clamps or a vise.

- Keep hands and fingers away from the cutting blade.

- Use proper cutting techniques and avoid overloading the cutter.

- Dispose of scrap metal safely and properly.

2. Describe the different types of steel cutters you have experience with and their specific applications.

Plasma Cutters

- Use a high-temperature plasma arc to cut through conductive metals.

- Suitable for cutting intricate shapes and clean cuts.

Oxy-Fuel Cutters

- Use a flame to heat the metal to its melting point, then use a jet of oxygen to blow away the molten metal.

- Capable of cutting thick sections of metal, but can produce a rougher cut.

Laser Cutters

- Use a high-powered laser beam to melt and vaporize the metal.

- Produce very precise and intricate cuts.

3. How do you determine the correct cutting speed and pressure for different types of steel?

- Consider the thickness and hardness of the steel.

- Refer to manufacturer’s specifications or cutting charts for recommended settings.

- Adjust settings based on experience and the desired cut quality.

4. What are some common problems that can occur when operating a steel cutter?

- Blade dullness

- Improper cutting techniques

- Equipment malfunctions

- Safety hazards

5. How do you troubleshoot and resolve common steel cutter problems?

- Inspect the blade for dullness and replace if necessary.

- Check for loose connections or damaged components.

- Refer to the manufacturer’s user manual for troubleshooting guidance.

- Contact a qualified technician for complex issues.

6. What are the different welding techniques used to join steel?

- Arc welding (e.g., MIG, TIG, Stick)

- Gas welding (e.g., oxy-acetylene)

- Resistance welding (e.g., spot welding)

- Brazing

7. Describe the process of welding two pieces of steel together using an arc welder.

MIG (Metal Inert Gas) Welding

- Clean and prepare the steel surfaces.

- Set up the welder according to the material thickness.

- Wear a welding helmet and protective gear.

- Hold the welding gun perpendicular to the joint.

- Use a filler rod to feed metal into the weld pool.

8. What are some of the common welding defects and how can they be prevented?

- Porosity (caused by entrapped gases): Use proper shielding gas and clean materials.

- Undercut (groove at the edge of the weld): Use correct welding parameters and avoid excessive heat.

- Cold lap (lack of fusion between weld layers): Preheat the steel or increase welding heat.

- Slag inclusions (trapped impurities): Remove slag before welding and use proper flux.

9. How do you inspect a weld to ensure its quality?

- Visual inspection for defects (e.g., cracks, porosity).

- Non-destructive testing (e.g., X-ray, ultrasound) to detect internal flaws.

- Review weld documentation (e.g., weld logs, inspection reports).

10. What are your career goals and aspirations?

- To become a highly skilled and experienced steel cutter.

- To contribute to the successful completion of projects by providing precise and efficient steel cutting.

- To stay up-to-date on the latest techniques and technologies in the steel cutting industry.

- To advance to a leadership role and train and mentor other steel cutters.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel cutters are skilled workers who use specialized equipment and techniques to cut and shape steel into various forms. Their primary responsibilities include:1. Cutting and Shaping Steel:

- Operating cutting machines, such as plasma cutters, laser cutters, or oxy-fuel torches, to precision-cut steel into specific shapes and sizes.

- Measuring and marking steel using rulers, calipers, and other measuring tools to ensure accurate cuts.

- Using jigs and fixtures to hold the steel in place during cutting.

2. Quality Control:

- Inspecting cut steel for defects using visual inspection or specialized equipment.

- Ensuring that cuts meet the specified dimensions, tolerances, and quality standards.

3. Machine Maintenance:

- Performing routine maintenance on cutting equipment, including cleaning, lubricating, and calibrating.

- Troubleshooting and repairing minor equipment malfunctions.

4. Material Handling:

- Loading and unloading steel sheets or plates into and out of cutting machines.

- Using hoists, cranes, or forklifts to move heavy steel objects.

- Ensuring proper storage and handling of steel materials.

5. Safety Compliance:

- Following established safety procedures and wearing appropriate personal protective equipment (PPE)

- Maintaining a safe and clean work environment.

Interview Tips

Preparation is key to acing any job interview. Here are some tips to help you stand out as a Steel Cutter candidate:1. Research the Company and Position:

- Visit the company website to learn about their history, products/services, and industry reputation.

- Review the job description thoroughly to understand the specific responsibilities and requirements.

2. Highlight Relevant Experience and Skills:

- In your resume and during the interview, emphasize your experience in steel cutting, including the types of machines you have operated.

- Showcase your knowledge of cutting techniques, quality control standards, and safety procedures.

3. Practice Common Interview Questions:

- Prepare for questions about your experience, skills, and why you are interested in the position.

- Rehearse your answers to common behavioral questions, using the STAR method (Situation, Task, Action, Result).

4. Prepare Industry-Specific Questions:

- Research the latest trends and advancements in steel cutting technology.

- Prepare questions to ask the interviewer about the company’s equipment, processes, and safety protocols.

5. Dress Professionally and Arrive on Time:

- Dress appropriately for the industry and company culture.

- Plan your route and arrive at the interview location on time, demonstrating your punctuality and respect for the interviewer’s time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Steel Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Steel Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.