Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Steel Die Engraver position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

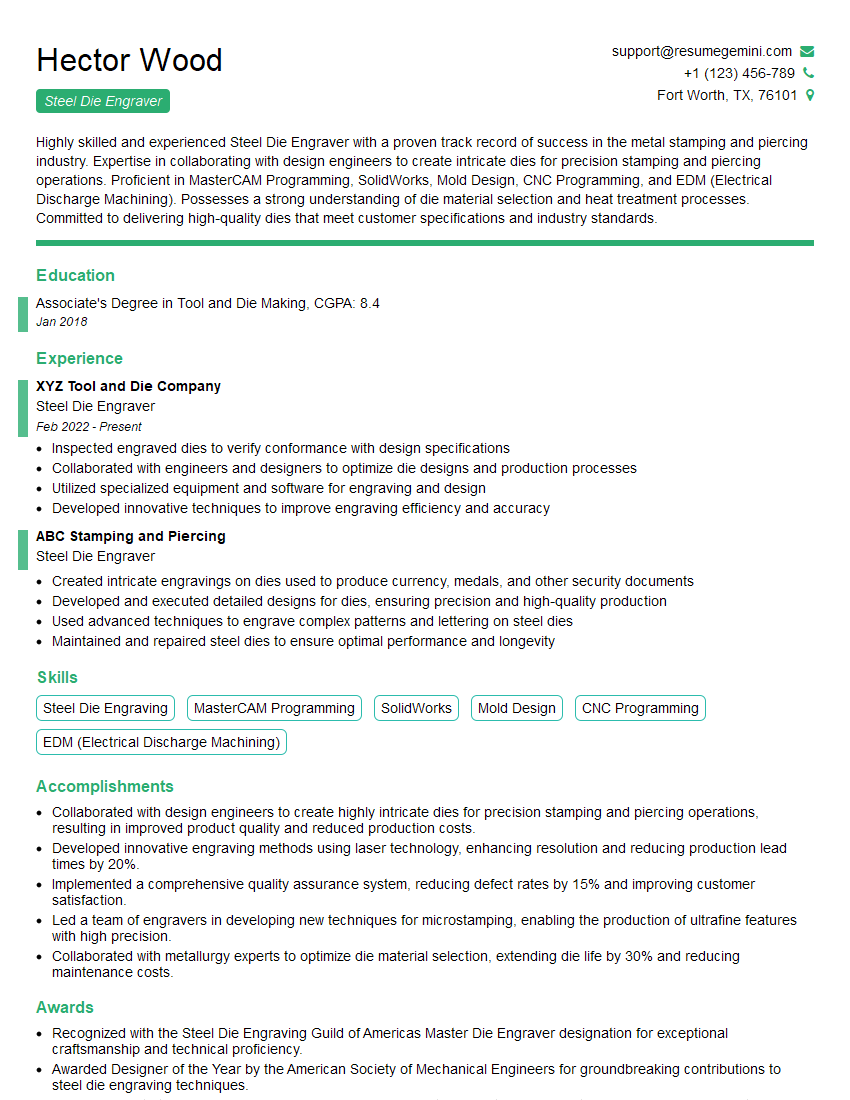

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Die Engraver

1. What are the different types of steel used in die engraving, and what are their specific characteristics?

- D2 tool steel: High wear resistance, good toughness, and machinability. Used for fine detail engraving and stamping.

- S7 tool steel: Excellent toughness and wear resistance. Used for heavy-duty applications and coining.

- A2 tool steel: High hardness, abrasion resistance, and toughness. Used for high-volume production and cutting tools.

- H13 tool steel: High strength, good toughness, and heat resistance. Used for hot work dies and forging applications.

- M2 high-speed steel: High cutting speed and wear resistance. Used for machining and engraving hard materials.

2. Describe the process of annealing steel for die engraving.

Heating

- Heat the steel to a specific temperature, typically within the range of 1400-1550°F (760-843°C).

- Hold the steel at the annealing temperature for a sufficient time, usually 15-30 minutes per inch of thickness.

Cooling

- Slowly cool the steel at a controlled rate, typically in a furnace or oven.

- The cooling rate should be gradual enough to prevent the steel from hardening or cracking.

3. What are the main considerations when selecting a die engraving machine?

- Precision and accuracy: The machine should be able to produce fine and precise engravings with consistent results.

- Speed and efficiency: The machine should be capable of engraving at a reasonable speed and with high throughput.

- Material compatibility: The machine should be suitable for engraving the desired type of steel and other materials.

- Ease of use and maintenance: The machine should be user-friendly, with intuitive controls and easy maintenance procedures.

- Cost and availability: Factors such as the initial investment, maintenance costs, and availability of replacement parts should also be considered.

4. Describe the techniques used for hardening steel dies.

- Heat treatment: Heating the steel to a high temperature and then rapidly cooling it, such as by quenching in water or oil.

- Induction hardening: Using an induction coil to generate heat specifically in the areas that need hardening.

- Flame hardening: Using a high-temperature flame to heat localized areas of the steel.

- Nitriding: Diffusing nitrogen into the surface of the steel to create a hard and wear-resistant layer.

5. What are the common errors or challenges encountered during steel die engraving, and how are they addressed?

- Undercutting: When the engraving tool cuts below the desired depth, leading to weakened areas. This can be corrected by adjusting the tool’s feed rate or using a tool with a smaller diameter.

- Burring: When excess material accumulates around the edges of the engraving. This can be removed using a deburring tool or by hand with files or abrasives.

- Tool wear: As engraving tools are used, they wear down and become less effective. Tools should be regularly inspected and replaced as needed to maintain precision.

- Material defects: Imperfections in the steel, such as inclusions or cracks, can affect the quality of the engraving. These defects may need to be repaired or the material replaced.

6. How do you ensure the accuracy and consistency of die engravings?

- Using high-precision engraving machines that are regularly calibrated and maintained.

- Employing skilled and experienced engravers who adhere to established standards and specifications.

- Implementing quality control procedures, including visual inspections and dimensional measurements, to verify the accuracy of the engravings.

- Utilizing CAD/CAM software to create precise engraving designs and toolpaths.

7. What is the difference between a steel die engraver and a mold engraver?

- Steel Die Engraver:

- Specializes in creating dies for stamping or forging metal parts.

- Produces intricate designs and patterns in steel using hand engraving tools or CNC machines.

- Ensures that the dies meet precise specifications and have a long lifespan.

- Mold Engraver:

- Focuses on creating molds for casting plastic, rubber, or metal parts.

- Etches or carves designs into a mold material, creating the negative of the desired shape.

- Ensures that the molds produce consistent and high-quality parts.

8. What software programs are commonly used in the steel die engraving industry?

- CAD/CAM software, such as AutoCAD, SolidWorks, or Mastercam, for designing and generating toolpaths.

- Engraving software, such as Gravograph or EnRoute, for controlling the engraving machine and creating artistic designs.

- Inspection software, such as Verisurf or Geomagic, for verifying the accuracy and dimensions of engravings.

9. How do you stay updated with the latest advancements in steel die engraving techniques and technologies?

- Attending industry conferences and exhibitions.

- Reading trade magazines and technical journals.

- Participating in online forums and discussion groups.

- Networking with other steel die engravers and industry professionals.

- Consulting with equipment manufacturers and software developers.

10. What is your approach to continuous improvement in your role as a steel die engraver?

- Regularly evaluating current processes and identifying areas for improvement.

- Seeking feedback from colleagues, supervisors, and clients to gain insights into areas that need enhancement.

- Exploring new techniques, technologies, and materials to improve accuracy, efficiency, and quality.

- Engaging in ongoing training and professional development to enhance skills and knowledge.

- Implementing new best practices and sharing knowledge with team members to foster a culture of continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Die Engraver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Die Engraver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Die Engravers are skilled artisans responsible for creating intricate designs and patterns on steel dies used for a variety of purposes, including printing, embossing, and stamping. Their key job responsibilities include:

1. Design and Development

Collaborate with designers and engineers to develop new die designs that meet customer specifications.

- Create detailed drawings and sketches of die designs using CAD software.

- Develop prototypes and models to ensure designs meet functional and aesthetic requirements.

2. Die Engraving

Use specialized tools and techniques to engrave designs onto hardened steel dies.

- Select appropriate engraving tools and materials for specific designs.

- Engrave designs with high precision and accuracy, paying attention to detail and tolerances.

3. Die Maintenance and Repair

Inspect and maintain dies regularly to ensure optimal performance.

- Sharpen and clean engraving tools as needed.

- Repair or replace worn or damaged dies to extend their lifespan.

4. Quality Control and Testing

Evaluate the quality of engraved dies and conduct testing to ensure they meet specifications.

- Use measuring tools and equipment to verify dimensions and tolerances.

- Conduct press trials to test the performance of dies in production environments.

Interview Tips

To ace your Steel Die Engraver interview, prepare thoroughly and follow these tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s products, services, and industry trends.

- Review the company website, industry publications, and news articles.

- Identify the company’s key competitors and their market share.

2. Showcase Your Skills and Experience

Highlight your technical proficiency in die engraving and your understanding of the industry.

- Quantify your accomplishments using specific examples and metrics.

- Describe your experience with different die engraving techniques and materials.

3. Prepare for Technical Questions

Review common interview questions related to die engraving techniques, design principles, and quality control procedures.

- Practice answering questions about your experience with specific engraving tools and equipment.

- Be prepared to discuss the different types of dies you have engraved and their applications.

4. Ask Thoughtful Questions

Show your interest in the company and the role by asking insightful questions about the company’s culture, growth opportunities, and challenges.

- Ask about the company’s investment in new technologies or emerging trends.

- Inquire about the opportunities for professional development and advancement within the organization.

5. Dress Professionally and Arrive on Time

Make a good impression by dressing appropriately and arriving for your interview on time.

- Consider wearing business attire or a professional outfit that reflects the company’s culture.

- Arrive early to allow yourself ample time to relax and gather your thoughts before the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Steel Die Engraver interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.