Are you gearing up for a career in Steel Die Press Set Up Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Steel Die Press Set Up Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

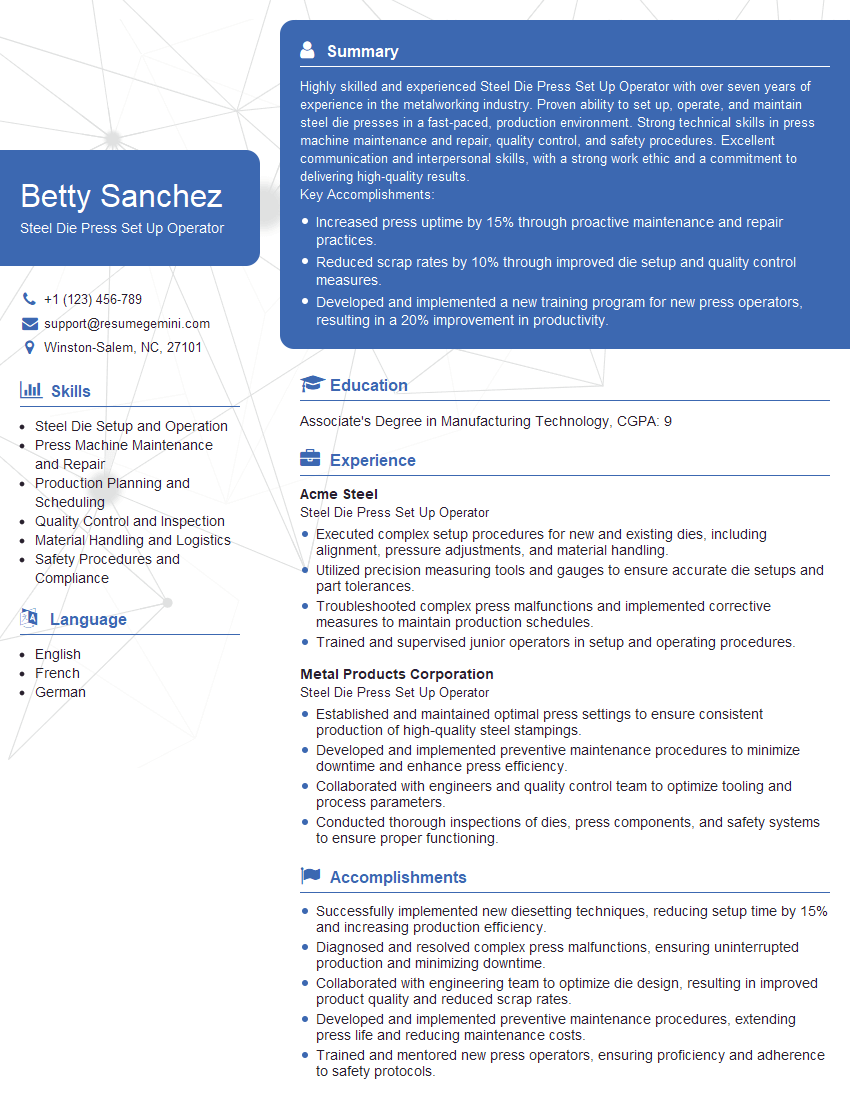

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Die Press Set Up Operator

1. How do you determine the correct die clearance for a given material and thickness?

To determine the correct die clearance for a given material and thickness, I follow a standardized procedure:

- Consult manufacturer’s recommendations for the specific material and thickness.

- Measure the material thickness using a micrometer.

- Use a clearance calculator or formula to calculate the appropriate die clearance based on the thickness and material properties.

- Set the die clearance accordingly using adjustment screws or shims.

- Verify the clearance with a feeler gauge or test run the press.

2. What are the key steps involved in setting up a progressive die press?

Setting Up a Progressive Die Press

- Inspect the die for any damage or wear.

- Install the die into the press and align it properly.

- Set the press speed and pressure according to specifications.

- Load the material into the feed and align it with the die.

- Adjust the feed rate and tension to ensure smooth material flow.

- Lubricate the die components as per the manufacturer’s instructions.

- Monitor the press operation and make adjustments as necessary.

Safety Measures

- Wear appropriate safety gear.

- Lock out and tag the press before making any adjustments.

- Keep hands away from moving parts.

- Follow all established safety protocols.

3. How do you troubleshoot common press brake problems, such as chatter or burring?

To troubleshoot common press brake problems, I utilize a systematic approach:

- Chatter:

- Check for proper die alignment.

- Inspect the die for wear or damage.

- Adjust the press speed or pressure.

- Lubricate the die components.

- Burring:

- Check for dull or damaged tooling.

- Adjust the die clearance or hold-down pressure.

- Use a lubricant with anti-burring properties.

- Other Problems:

- Inspect for loose bolts or other mechanical issues.

- Check for proper material alignment and feeding.

- Monitor the press for any unusual noises or vibrations.

4. How do you ensure the accuracy and precision of parts produced on a steel die press?

To ensure the accuracy and precision of parts produced on a steel die press, I implement several key practices:

- Use precision measuring instruments, such as micrometers and calipers, to verify material dimensions and die settings.

- Inspect the die regularly for wear or damage and make necessary adjustments.

- Follow established setup and operating procedures to minimize variability.

- Monitor the press performance and make adjustments as needed to maintain accuracy.

- Implement statistical process control techniques to track and improve part quality.

5. How do you handle different types of materials, such as high-strength steel or aluminum alloys?

To handle different types of materials effectively, I consider several factors:

- Material Properties: Research the material’s strength, hardness, and formability characteristics.

- Die Design: Adjust die settings, such as clearance and hold-down pressure, to suit the material’s properties.

- Tooling: Select appropriate tooling materials and coatings based on the material’s abrasiveness and wear resistance.

- Lubrication: Choose lubricants specifically designed for the material to minimize friction and improve formability.

- Process Monitoring: Pay close attention to the press operation and adjust parameters as needed to ensure optimal results.

6. What maintenance procedures do you perform on a steel die press to ensure its longevity?

To ensure the longevity of a steel die press, I adhere to regular maintenance procedures:

- Daily: Inspect the press for any visible issues, leaks, or unusual noises.

- Weekly: Lubricate moving parts, clean the press bed, and check fluid levels.

- Monthly: Perform a more thorough inspection, including checking for wear on dies, tooling, and bearings.

- Quarterly: Conduct a comprehensive maintenance plan, including replacing worn components and calibrating the press.

- Annually: Schedule a major overhaul, involving inspection and replacement of all critical components.

7. How do you work with other team members to ensure efficient production?

To promote efficient production as a team, I actively engage in the following practices:

- Communication: Maintain open communication with team members to discuss production goals, challenges, and solutions.

- Collaboration: Work closely with other operators, supervisors, and engineers to optimize setups and address any issues promptly.

- Cross-Training: Share knowledge and skills with colleagues to ensure backup coverage and improve overall team performance.

- Continuous Improvement: Participate in discussions and initiatives aimed at improving processes and increasing productivity.

8. How do you stay up-to-date with the latest advancements in steel die press technology?

To stay current with advancements in steel die press technology, I actively pursue the following strategies:

- Attend industry conferences and workshops.

- Read technical articles and journals.

- Consult with equipment manufacturers and suppliers.

- Participate in online forums and discussion groups.

- Explore new technologies and techniques through research and experimentation.

9. What are your strengths and weaknesses as a Steel Die Press Set Up Operator?

My strengths as a Steel Die Press Set Up Operator include:

- Technical Expertise: In-depth understanding of steel die press operations, die design, and material properties.

- Precision and Accuracy: Ability to set up and operate presses to achieve high-quality parts.

- Problem-Solving: Strong analytical skills and experience in troubleshooting and resolving press issues.

- Maintenance and Repair: Proficient in performing routine maintenance and repairs to ensure press longevity.

- Safety-Conscious: Adherence to safety protocols and a proactive approach to risk management.

Areas where I seek to improve include:

- Advanced Die Design: Expanding my knowledge of complex die design principles.

- Automated Processes: Exploring opportunities to incorporate automation into press operations.

- Lean Manufacturing: Refining my understanding of lean principles to enhance efficiency.

10. Do you have any questions for me about the position or the company?

I am interested in learning more about the company’s commitment to innovation and the opportunities for professional growth within the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Die Press Set Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Die Press Set Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Die Press Set Up Operators play a crucial role in ensuring the smooth functioning of production lines. Their responsibilities encompass the following key areas:

1. Machine Set Up and Maintenance

Meticulously set up and calibrate steel die presses according to specifications.

- Identify and install appropriate dies, tooling, and materials.

- Conduct thorough inspections and adjustments to ensure optimal press performance.

- Monitor press operations and identify any potential malfunctions or inefficiencies.

2. Material Handling and Inspection

Properly handle and inspect raw materials to ensure quality standards are met.

- Receive and inspect incoming materials, verifying dimensions, tolerances, and surface finish.

- Feed materials into the press and monitor the forming process.

- Inspect finished products for defects and ensure they meet established specifications.

3. Quality Control and Troubleshooting

Continuously monitor production to maintain high-quality standards.

- Conduct regular quality checks throughout the production process.

- Identify and analyze defects, implementing corrective actions to minimize errors.

- Troubleshoot press malfunctions and resolve issues promptly to minimize downtime.

4. Production Optimization

Analyze production processes to identify areas for improvement.

- Monitor press productivity and identify bottlenecks or inefficiencies.

- Implement process improvements to increase production efficiency.

- Collaborate with other departments to optimize material flow and reduce waste.

Interview Tips

To excel in a Steel Die Press Set Up Operator interview, candidates should consider the following tips:

1. Research the Company and Position

Thoroughly research the company’s history, industry, and current projects. Understand the specific requirements of the Steel Die Press Set Up Operator position.

- Identify the company’s goals and how your skills align with their objectives.

- Review the job description and highlight the experiences and qualifications that match the specified criteria.

2. Quantify Your Accomplishments

Use specific metrics and numbers to quantify your accomplishments. This will provide tangible evidence of your impact in previous roles.

- Example: “Increased production efficiency by 15% through process optimization and waste reduction.”

- Example: “Reduced product defects by 20% through enhanced quality control measures.”

3. Showcase Your Technical Expertise

Demonstrate your proficiency in setting up and operating steel die presses. Highlight your understanding of different types of presses, materials, and tooling.

- Discuss your experience in using specific press models or specialized equipment.

- Explain your knowledge of press safety protocols and troubleshooting techniques.

4. Emphasize Problem-Solving Skills

Interviewers seek candidates who can identify and resolve problems effectively. Share examples where you successfully diagnosed and fixed technical issues.

- Example: “Resolved a press malfunction that was causing excessive product defects. The issue was traced to a faulty sensor, which I replaced, resulting in improved production quality.”

- Example: “Identified a bottleneck in the production process and proposed a solution that streamlined material flow, increasing production efficiency by 10%.”

5. Highlight Your Communication and Teamwork Skills

Steel Die Press Set Up Operators often work in teams and interact with various departments. Showcase your communication skills and ability to collaborate effectively.

- Example: “Collaborated with design engineers to optimize die design for better product quality and reduced production time.”

- Example: “Effectively communicated technical information and process updates to team members, ensuring smooth coordination and problem resolution.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Steel Die Press Set Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!