Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Steel Hanger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

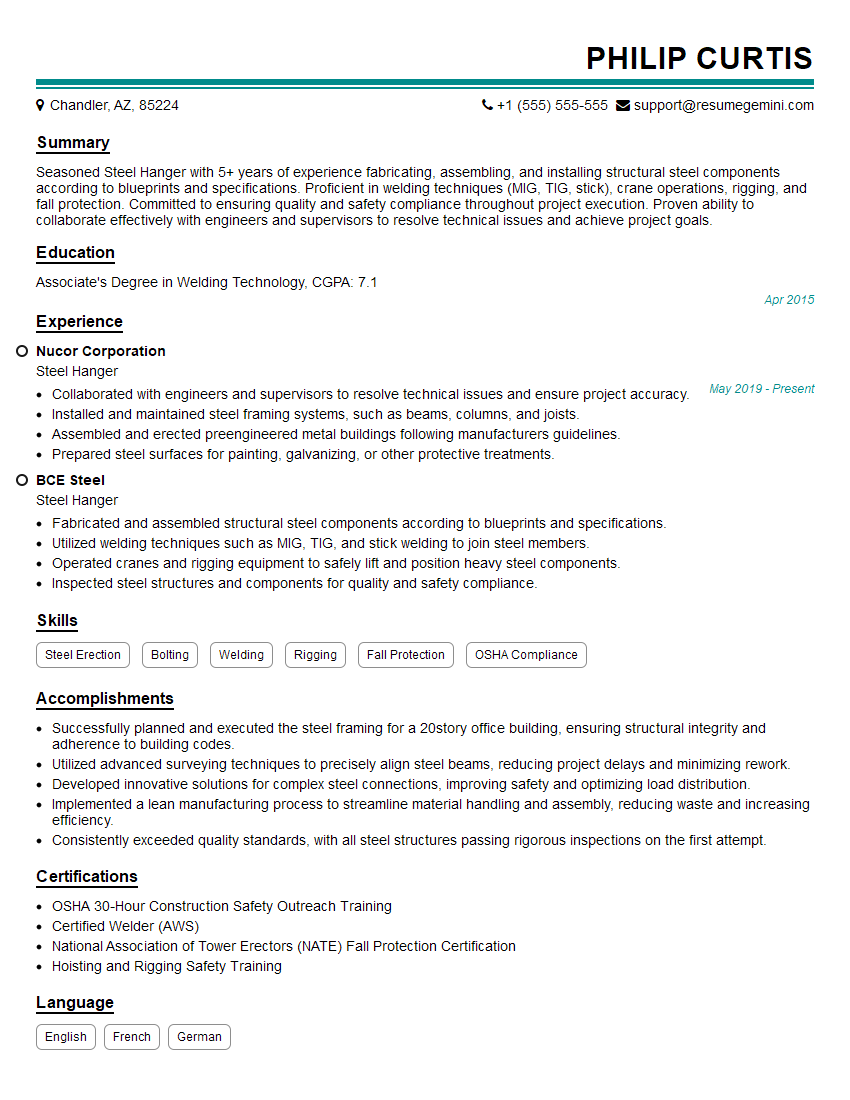

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Hanger

1. What are the different types of steel hangers, and how do you choose the right one for a particular application?

There are three main types of steel hangers: top-mount, side-mount, and band hangers. Top-mount hangers are used to support loads from above, while side-mount hangers are used to support loads from the side. Band hangers are used to support pipes and conduits from ceilings and walls.

- To choose the right hanger for a particular application, you need to consider the following factors:

- The weight of the load

- The location of the load

- The type of material being supported

- The environment in which the hanger will be used

2. What are the different materials used to make steel hangers, and what are the advantages and disadvantages of each?

Carbon Steel

- Advantages:

- Strong and durable

- Inexpensive

- Disadvantages:

- Susceptible to corrosion

Stainless Steel

- Advantages:

- Resistant to corrosion

- Strong and durable

- Disadvantages:

- More expensive than carbon steel

Aluminum

- Advantages:

- Lightweight

- Resistant to corrosion

- Disadvantages:

- Not as strong as steel

- More expensive than steel

3. What are the different finishes available for steel hangers, and what are the advantages and disadvantages of each?

Zinc-Plated

- Advantages:

- Protects against corrosion

- Inexpensive

- Disadvantages:

- Not as durable as other finishes

Hot-Dip Galvanized

- Advantages:

- Provides excellent corrosion protection

- Durable and long-lasting

- Disadvantages:

- More expensive than zinc-plating

Powder-Coated

- Advantages:

- Available in a wide range of colors

- Durable and resistant to chipping and scratching

- Disadvantages:

- Can be more expensive than other finishes

4. What are the different sizes of steel hangers available, and how do you determine the correct size for a particular application?

Steel hangers are available in a wide range of sizes, from small hangers that can support a few pounds to large hangers that can support thousands of pounds. To determine the correct size hanger for a particular application, you need to consider the following factors:

- The weight of the load

- The type of hanger being used

- The material being supported

- The environment in which the hanger will be used

5. What are the different codes and standards that apply to the installation of steel hangers, and how do you ensure compliance?

There are a number of codes and standards that apply to the installation of steel hangers, including the International Building Code (IBC), the National Electrical Code (NEC), and the Uniform Plumbing Code (UPC). To ensure compliance with these codes and standards, you should always follow the manufacturer’s installation instructions and consult with a qualified engineer or architect.

6. What are the different tools and equipment required to install steel hangers, and how do you use them safely?

- Drill

- Screwdriver

- Wrench

- Hammer

- Safety glasses

- Gloves

To use these tools and equipment safely, you should always follow the manufacturer’s instructions and wear appropriate personal protective equipment (PPE).

7. What are the different methods for installing steel hangers, and what are the advantages and disadvantages of each?

Screw-in

- Advantages:

- Quick and easy to install

- Inexpensive

- Disadvantages:

- Not as strong as other methods

- Can damage the substrate if not installed properly

Bolt-on

- Advantages:

- Strong and secure

- Can be used to support heavy loads

- Disadvantages:

- More time-consuming to install

- Requires more tools and equipment

Welding

- Advantages:

- Provides the strongest and most secure connection

- Can be used to support very heavy loads

- Disadvantages:

- Requires specialized tools and equipment

- Can be dangerous if not performed properly

8. What are the different factors that can affect the performance of steel hangers, and how do you mitigate these factors?

Corrosion

- Mitigate:

- Use corrosion-resistant materials

- Apply protective coatings

- Install hangers in a dry environment

Overloading

- Mitigate:

- Choose the right size hanger for the load

- Install hangers at the proper spacing

- Avoid overloading hangers

Improper Installation

- Mitigate:

- Follow the manufacturer’s installation instructions

- Use the proper tools and equipment

- Hire a qualified contractor to install hangers

9. What are the different types of inspections that should be performed on steel hangers, and how often should they be performed?

Visual Inspection

- Inspect hangers for:

- Corrosion

- Damage

- Loose connections

- Frequency:

- Monthly

Load Testing

- Test hangers to ensure they can support the intended load

- Frequency:

- Annually

10. What are the different maintenance tasks that should be performed on steel hangers, and how often should they be performed?

- Inspect hangers for corrosion, damage, and loose connections

- Frequency:

- Monthly

- Tighten loose connections

- Frequency:

- As needed

- Lubricate moving parts

- Frequency:

- As needed

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Hanger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Hanger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Steel Hanger is responsible for installing, maintaining, and repairing steel structures in various industrial and construction settings. Their duties may include:

1. Steel Erection

Assemble and erect steel structures such as bridges, buildings, and towers.

- Follow blueprints, shop drawings, and specifications to ensure accurate and safe installation

- Use specialized tools and equipment to hoist, position, and secure steel members

2. Welding and Fabrication

Perform welding tasks to join steel components and fabricate custom parts.

- Use shielded metal arc welding (SMAW), gas metal arc welding (GMAW), or flux-cored arc welding (FCAW)

- Prepare and clean metal surfaces, and inspect welds for quality and compliance

3. Rigging and Lifting

Operate cranes and hoists to lift and move heavy steel components.

- Plan and execute lifting operations, considering weight capacities and safety protocols

- Inspect and maintain rigging equipment, such as slings, shackles, and hooks

4. Maintenance and Repair

Inspect and maintain existing steel structures for damage or wear.

- Identify and repair structural defects, such as cracks, corrosion, or loose bolts

- Perform non-destructive testing (NDT) to evaluate the condition of steel structures

Interview Tips

To ace the interview for a Steel Hanger position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge about the company, its projects, and the broader steel industry.

- Visit the company’s website and review their recent projects

- Read articles and industry publications to gain insights into current trends and best practices

2. Highlight Relevant Skills and Experience

Emphasize your skills in steel erection, welding, rigging, and maintenance.

- Quantify your experience whenever possible, using specific numbers and examples

- Provide evidence of your welding certifications and NDT training

3. Showcase Safety and Teamwork

Steel hanging is a safety-critical role that requires effective teamwork. Highlight your commitment to safety and your ability to work collaboratively.

- Discuss your understanding of safety protocols and your experience working in a team environment

- Share examples of how you have contributed to safety initiatives or resolved conflicts on previous projects

4. Ask Insightful Questions

Ask thoughtful questions about the company, the project, and the role to demonstrate your interest and engagement.

- Inquire about the company’s approach to safety and quality

- Ask about the specific challenges or opportunities associated with the project you’re applying for

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Steel Hanger interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!