Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Steel Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Steel Molder so you can tailor your answers to impress potential employers.

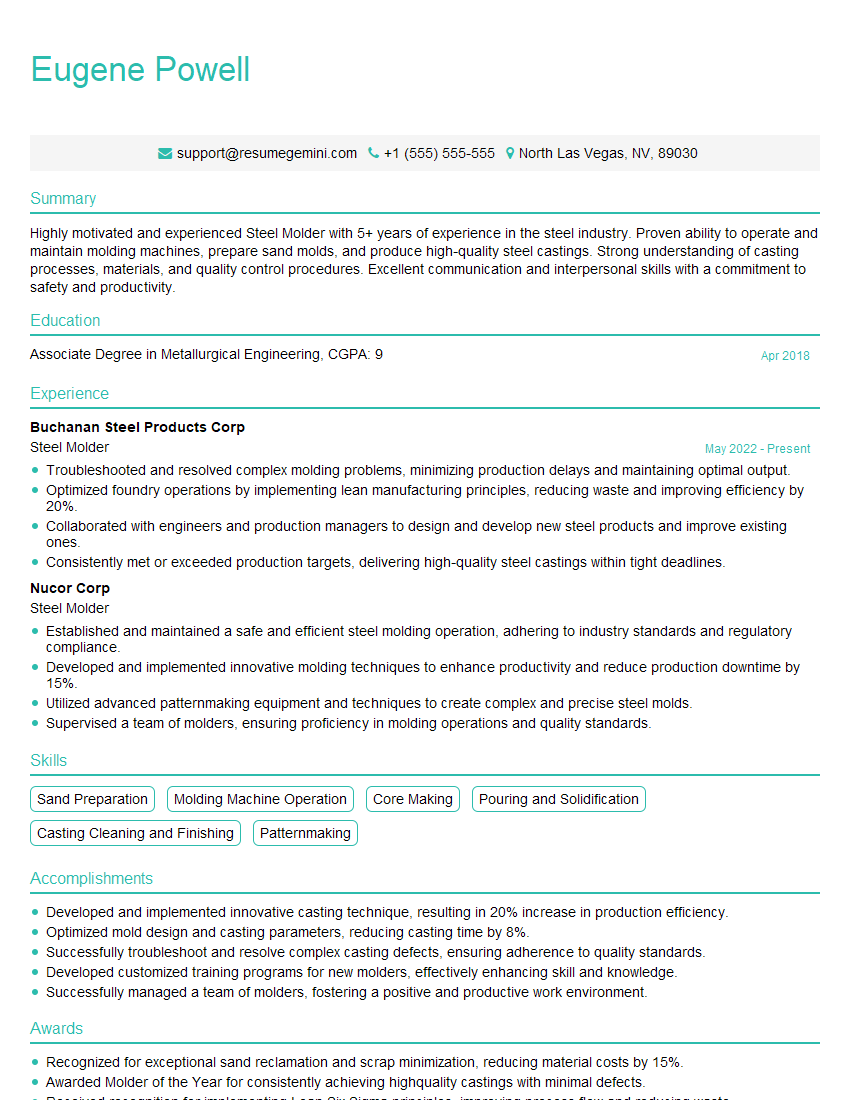

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Molder

1. Explain the process of making molds for steel casting?

The process of making molds for steel casting involves several steps:

- Patternmaking: Creating a pattern that represents the desired shape of the casting.

- Molding: Forming the mold cavity using sand, clay, or other materials around the pattern.

- Coremaking: Creating internal cavities in the casting using cores made of sand or ceramic materials.

- Assembly: Joining the mold halves and cores to create the complete mold cavity.

- Pouring: Molten steel is poured into the mold cavity and allowed to solidify and cool.

- Shakeout: Breaking the mold and removing the solidified casting.

2. What are the different types of molding methods used in steel casting?

Sand Casting

- Uses sand as the molding material.

- Versatile and suitable for large or complex castings.

Investment Casting

- Uses a wax pattern coated with ceramic material.

- Produces intricate and high-precision castings.

Die Casting

- Uses metal dies to force molten metal into the mold.

- Suitable for mass production of small, precise castings.

3. What factors influence the selection of molding materials for steel casting?

Factors that influence the selection of molding materials include:

- Material properties: Thermal conductivity, strength, and resistance to erosion.

- Casting size and complexity: Mold materials must be able to withstand the forces and temperatures involved.

- Production volume: Different materials have varying costs and production rates.

- Environmental considerations: Some materials may pose health or environmental hazards.

4. Describe the process of melting and pouring steel for casting?

Melting

- Steel is melted in an electric arc furnace or induction furnace.

- Alloying elements are added to achieve the desired properties.

Pouring

- Molten steel is poured into ladles and transported to the casting area.

- Pouring techniques aim to minimize turbulence and oxidation.

5. Explain the importance of solidification and cooling in steel casting?

Solidification and cooling influence the microstructure and properties of the casting:

- Solidification: Controlled cooling rates and directional solidification promote desired grain structure and minimize defects.

- Cooling: Proper cooling rates prevent cracking, reduce residual stresses, and ensure optimal mechanical properties.

6. What are the common defects that can occur in steel castings and how can they be prevented?

Defects

- Cracks: Caused by excessive thermal stresses or shrinkage.

- Porosity: Trapped air or gas pockets.

- Inclusions: Foreign particles in the casting.

Prevention

- Optimized mold design: Reduce stress concentrations.

- Proper gating and feeding systems: Control solidification and prevent porosity.

- Melting and pouring practices: Minimize contamination and inclusions.

7. Explain the role of heat treatment in steel casting?

Heat treatment processes such as annealing, tempering, and quenching are applied to:

- Improve mechanical properties: Enhance strength, hardness, and toughness.

- Relieve residual stresses: Prevent cracking during cooling.

- Modify microstructure: Alter grain size and distribution.

8. Describe the different testing methods used to assess the quality of steel castings?

Destructive Testing

- Tensile testing: Measures strength and ductility.

- Impact testing: Assesses toughness and energy absorption.

Non-Destructive Testing

- Ultrasonic testing: Detects internal flaws using sound waves.

- Radiographic testing: Uses X-rays or gamma rays to reveal internal structures.

9. What are the safety precautions to be followed in a steel casting environment?

Hazards

- Molten metal: Risk of burns and splashes.

- Fumes and gases: Inhalation hazards.

- Heavy equipment: Potential for injuries or accidents.

Precautions

- Personal protective equipment: Protective clothing, gloves, and respirators.

- Safe work practices: Proper handling of molten metal and equipment.

- Regular training and supervision: Ensure employee understanding of safety procedures.

10. What are the emerging trends and innovations in the steel casting industry?

- Advanced simulation techniques: Predicting casting behavior and optimizing mold design.

- Additive manufacturing: Creating complex geometries and reducing lead times.

- Sustainable practices: Minimizing environmental impact and improving energy efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Molders are responsible for the production of steel castings, which are used in a variety of industries, including automotive, construction, and heavy equipment. Their duties include preparing molds, pouring molten steel into the molds, and removing the castings once they have solidified. Steel molders must have a strong understanding of the steel molding process and be able to work safely and efficiently in a foundry environment.

1. Prepare molds

The first step in the steel molding process is to prepare the mold. This involves creating a cavity in the sand that is the same shape as the desired casting. The molder must take into account the shrinkage that will occur as the steel cools and solidifies, so the mold must be slightly larger than the finished casting. The molder must also create a sprue and risers, which are channels that allow the molten steel to flow into the mold and escape as gases.

2. Pour molten steel into the mold

Once the mold is prepared, the steel is melted in a furnace and poured into the mold. The molder must carefully control the pouring process to ensure that the mold is completely filled and that there are no defects in the casting.

3. Remove the castings from the mold

Once the steel has solidified, the castings must be removed from the mold. The molder must use a variety of tools to break away the sand and remove the castings. The castings must then be cleaned and inspected for defects.

4. Repair defects

If any defects are found in the castings, the molder must repair them. This may involve welding, grinding, or other methods. The molder must ensure that the repaired castings meet the required standards.

Interview Preperation Tips

Here are some tips to help you ace your interview for a steel molder position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on its website, social media pages, and Glassdoor. You can also find information about the position in the job description.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” Prepare your answers to these questions in advance so that you can deliver them confidently and articulately.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about them. Focus on the skills and experience that are most relevant to the job you are applying for. You can also highlight any transferable skills that you have. For example, if you have experience in a different type of manufacturing, you can talk about how your skills in that area can be applied to the steel molding process.

4. Ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position. Ask questions about the company’s culture, the work environment, the training opportunities, and the advancement possibilities. Asking questions shows that you are interested in the job and that you are taking the interview seriously.

5. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt. You should also make sure your shoes are clean and polished.

6. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, call the interviewer to let them know. It is better to be late than is is to rush and appear disorganized.

7. Be enthusiastic

The interviewer will be able to tell if you are enthusiastic about the job, so make sure you show your excitement. Be positive and upbeat, and make sure you convey your interest in the position.

Next Step:

Now that you’re armed with the knowledge of Steel Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Steel Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini