Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Steel Pickler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Steel Pickler so you can tailor your answers to impress potential employers.

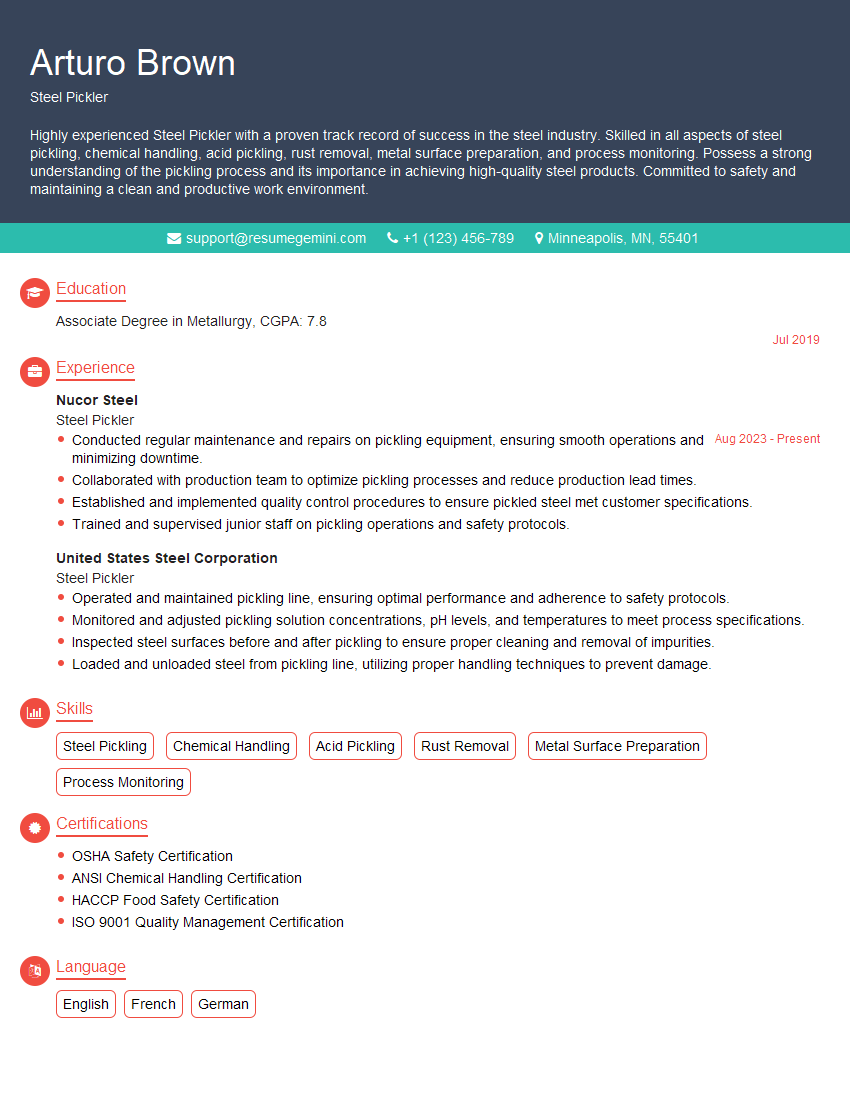

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Pickler

1. Which types of steel can be pickled?

As a Steel Pickler, I would be responsible for pickling various types of steel. Some of the most common steel grades that can be pickled include:

- Cold rolled steel

- Hot rolled steel

- Stainless steel

- Alloy steel

2. What is the purpose of pickling steel?

Removal of oxides

- The primary purpose of pickling steel is to remove surface oxides, which are formed during the manufacturing process.

- Oxides can impair the quality of the steel, making it more susceptible to corrosion and reducing its overall strength.

Surface preparation

- Pickling also serves as a surface preparation step for subsequent processing.

- By removing oxides and impurities, the surface of the steel becomes cleaner and more receptive to further treatments, such as coating or plating.

3. Describe the steps involved in the pickling process.

The pickling process typically involves the following steps:

- Pre-cleaning: The steel is initially cleaned to remove any loose dirt or contaminants.

- Immersion in acid solution: The steel is submerged in a pickling solution, typically composed of hydrochloric acid or sulfuric acid.

- Reaction and oxide removal: The acid solution reacts with the surface oxides, dissolving them and removing them from the steel.

- Neutralization: After pickling, the steel is neutralized to remove any residual acid and prevent further corrosion.

- Post-cleaning: The steel is rinsed and dried to remove any remaining solution or contaminants.

4. What factors influence the pickling time?

The pickling time is primarily determined by several factors:

- Type of steel: Different steel grades have varying oxide compositions and thicknesses, affecting the pickling time.

- Temperature: Higher temperatures accelerate the pickling reaction, reducing the required time.

- Acid concentration: A higher acid concentration increases the reaction rate, resulting in shorter pickling times.

- Agitation: Agitation during pickling enhances the contact between the acid solution and the steel surface, improving the pickling efficiency.

5. How do you control the quality of the pickled steel?

To ensure the quality of the pickled steel, several control measures are implemented:

- Visual inspection: The pickled steel is visually inspected for any surface defects or imperfections.

- Acid concentration monitoring: The acid concentration in the pickling solution is regularly monitored and adjusted to maintain optimal conditions.

- Temperature control: The temperature of the pickling solution is controlled within a specific range to ensure consistent pickling results.

- Pickling time optimization: The pickling time is carefully adjusted based on factors such as steel type and thickness to achieve the desired level of oxide removal.

6. What are the safety precautions that must be taken when handling pickling acids?

Handling pickling acids requires strict adherence to safety precautions:

- Proper protective gear: Wear gloves, protective clothing, and a respirator to prevent exposure to acids.

- Adequate ventilation: Ensure proper ventilation in the pickling area to minimize acid fumes.

- Spill containment: Have spill kits readily available to contain and neutralize any acid spills promptly.

- Training and supervision: Ensure that all personnel involved in handling acids are properly trained and supervised.

7. How do you troubleshoot common problems encountered during pickling?

In the event of problems during pickling, the following troubleshooting steps can be taken:

- Slow pickling rate: Check acid concentration, temperature, and agitation. Adjust accordingly to enhance the reaction rate.

- Uneven pickling: Inspect the steel surface for areas with inadequate pickling. Adjust the pickling time or solution composition to achieve uniform results.

- Surface defects: Determine the cause of defects, such as improper pre-cleaning, excessive pickling time, or contamination. Implement corrective measures to prevent recurrence.

- Acid contamination: Monitor the pickling solution regularly for any contaminants. If necessary, replace or filter the solution to maintain optimal pickling conditions.

8. What are the environmental regulations related to pickling operations?

Pickling operations are subject to environmental regulations to minimize the impact on the environment:

- Wastewater treatment: Spent acid solutions from pickling must be treated to neutralize acidity and remove heavy metals before disposal.

- Air emissions control: Fumes and gases generated during pickling must be controlled to comply with air quality regulations.

- Solid waste management: Spent pickling solutions and sludge must be disposed of in accordance with hazardous waste regulations.

- Employee health and safety: Proper ventilation and protective measures must be implemented to protect workers from exposure to hazardous substances.

9. What are the emerging technologies or advancements in pickling processes?

The pickling industry is constantly evolving, with new technologies and advancements emerging:

- Electrolytic pickling: This method uses an electric current to enhance the pickling process, reducing pickling time and improving surface quality.

- Ultrasonic pickling: Ultrasonic waves are used to improve the penetration of the acid solution into the steel surface, resulting in more efficient pickling.

- Environmentally friendly pickling solutions: Non-acidic or biodegradable pickling solutions are being developed to reduce environmental impact.

- Continuous pickling lines: Automated pickling lines are designed to improve efficiency and reduce labor costs.

10. What are the key performance indicators (KPIs) used to measure the effectiveness of a pickling operation?

The effectiveness of a pickling operation can be measured through several key performance indicators:

- Pickling time: The time required to achieve the desired level of oxide removal.

- Surface quality: The appearance and cleanliness of the pickled steel surface, free from defects or imperfections.

- Acid consumption: The amount of acid used per unit of steel pickled, indicating the efficiency of the pickling process.

- Wastewater generation: The volume of spent acid solution and sludge generated, which reflects the environmental impact.

- Safety record: The absence of accidents or incidents related to pickling operations, ensuring worker safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Pickler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Pickler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Picklers are responsible for the preparation of steel surfaces for further processing and protection against corrosion. Their key job responsibilities include:

1. Steel Surface Preparation

Preparing steel surfaces by removing rust, scale, and other contaminants using a variety of methods such as acid pickling, shot blasting, or abrasive blasting.

- Cleaning and preparing steel surfaces to meet specifications.

- Inspecting steel surfaces before and after pickling to ensure proper preparation.

2. Pickling Process

Operating and maintaining pickling lines to remove oxides and other impurities from steel surfaces.

- Controlling pickling parameters such as temperature, acid concentration, and immersion time.

- Monitoring and adjusting equipment to optimize the pickling process.

3. Chemical Handling

Handling and mixing pickling chemicals, including acids and other hazardous materials, safely and responsibly.

- Following safety procedures and wearing appropriate protective gear.

- Mixing and preparing pickling solutions according to established guidelines.

4. Equipment Maintenance

Maintaining and repairing pickling equipment, including tanks, pumps, and conveyors.

- Performing regular inspections and preventive maintenance tasks.

- Troubleshooting and resolving equipment malfunctions.

Interview Tips

To effectively prepare for an interview, consider the following tips and hacks:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. This will enable you to tailor your answers to the interviewer’s expectations and highlight your qualifications.

- Visit the company’s website to learn about their mission, values, and recent industry news.

- Check the company’s social media platforms for insights into their culture and workplace atmosphere.

2. Highlight Relevant Skills and Experience

Carefully review the job description and identify the skills and experience that are most relevant to the position. Emphasize these in your resume, cover letter, and during the interview.

- Quantify your accomplishments using specific examples and metrics.

- Use action verbs to describe your responsibilities and contributions.

3. Prepare for Common Interview Questions

Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” You can also anticipate industry-specific questions related to steel pickling processes and equipment.

- Prepare concise and well-structured answers that highlight your strengths.

- Consider using the STAR method (Situation, Task, Action, Result) to provide examples that demonstrate your abilities.

4. Demonstrate Your Safety Knowledge

Steel pickling involves handling hazardous chemicals and operating heavy machinery. Emphasize your understanding of safety procedures and regulations in the interview.

- Describe your experience with personal protective equipment (PPE) and safe chemical handling practices.

- Mention any safety certifications or training you have received.

5. Ask Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your engagement and interest in the position. It also gives you the opportunity to clarify any details and gain a better understanding of the company and the role.

- Prepare questions specific to the job description and industry.

- Avoid asking generic or personal questions that may come across as unprofessional.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Steel Pickler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.