Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Steel Pourer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

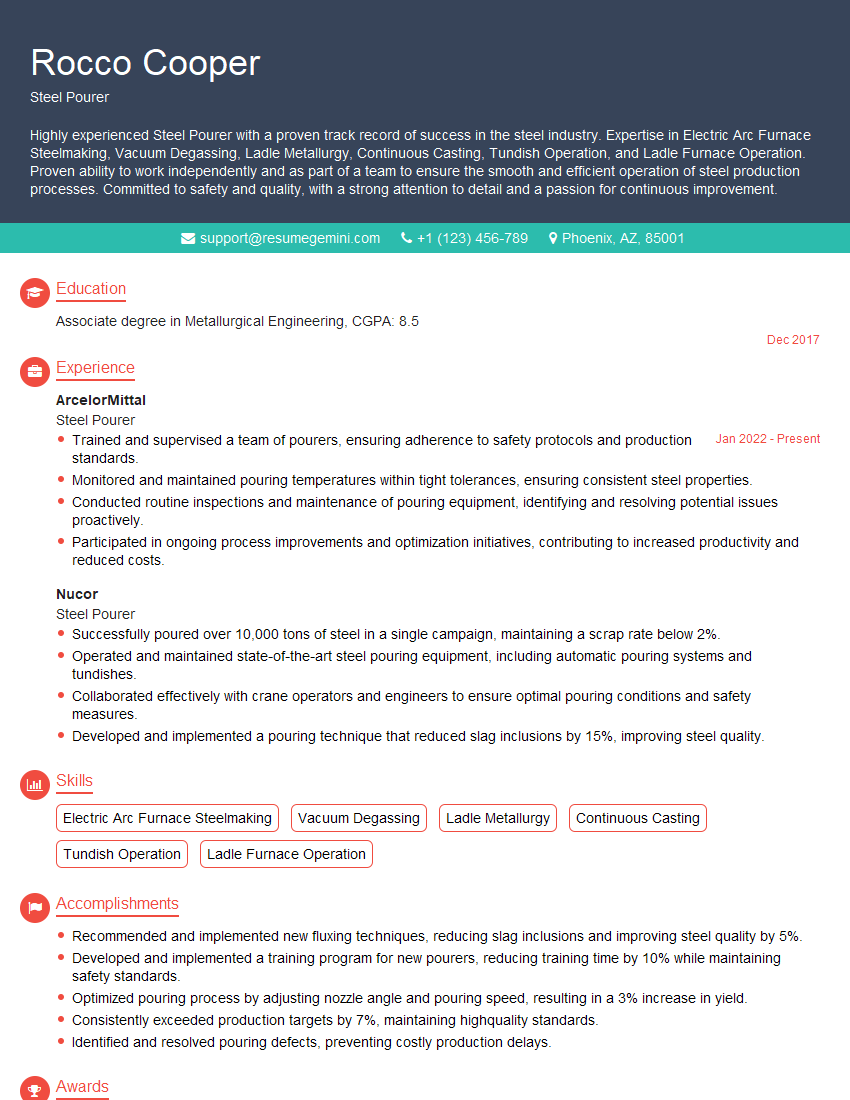

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Pourer

1. What is the purpose of slag and how do you control it?

Slag is a byproduct of steelmaking that forms on the surface of molten steel. It consists of impurities and oxides removed from the steel during the refining process.

- Control Slag Thickness: Slag thickness is critical for protecting the molten steel from oxidation and contamination. A slag that is too thick can hinder heat transfer, while a slag that is too thin can allow oxygen to penetrate and react with the steel.

- Control Slag Composition: Slag composition affects its viscosity, density, and reactivity. By adjusting the composition, we can optimize slag properties for specific steel grades and casting conditions.

- Prevent Slag Entrapment: Slag entrapment occurs when slag inclusions become trapped in the solidified steel. This can weaken the steel and cause defects. Proper slag control measures, such as using slag coagulants and controlling pouring temperatures, help prevent entrapment.

2. How do you determine the correct pouring temperature for different steel grades?

Factors Affecting Pouring Temperature:

- Steel grade and composition

- Casting size and shape

- Mold material and design

- Ambient temperature

Determining Pouring Temperature:

- Consult Steel Specifications: Steel manufacturers provide recommended pouring temperatures for different grades.

- Use Thermocouples: Thermocouples inserted into the molten steel provide accurate temperature measurements.

- Experience and Judgment: Experienced steel pourers rely on their knowledge and observations to estimate the appropriate pouring temperature based on visual cues, such as the fluidity of the steel.

3. Describe the safety precautions you follow during steel pouring operations.

- Wear appropriate personal protective equipment (PPE), including fire-resistant clothing, gloves, and a helmet.

- Maintain a safe distance from the molten steel and pouring equipment.

- Inspect equipment regularly for any signs of damage or wear.

- Follow established pouring procedures and avoid unauthorized modifications.

- Be aware of potential hazards such as spills, splashes, and explosions.

- Have emergency response plans in place and know how to use safety equipment.

- Receive regular safety training and updates.

4. What techniques do you use to minimize splashing and spills during pouring?

- Control Pouring Rate: Pouring too quickly can cause splashing. Adjust the pouring rate to minimize turbulence and maintain a steady stream.

- Use Pouring Nozzles: Pouring nozzles help direct the flow of molten steel and reduce splashing.

- Maintain Proper Ladle Height: Pouring from too high above the mold can increase the risk of spills and splashing.

- Clean Molds and Ladles: Dirt and debris in molds or ladles can cause splashing by creating pockets of gas or steam.

- Coordinate with Mold Operators: Communicate with mold operators to ensure the mold is properly positioned and ready to receive the molten steel.

5. Explain the importance of mold preparation and how you ensure it is done properly.

- Cleanliness: Molds must be thoroughly cleaned to remove any dirt, debris, or moisture that could contaminate the molten steel.

- Preheating: Preheat the mold to prevent thermal shock and ensure even solidification of the steel.

- Lubrication: Apply a mold lubricant to reduce friction between the steel and the mold, facilitating smooth casting.

- Inspection: Inspect the mold for any cracks, defects, or damage that could affect the casting.

- Coordination: Work closely with mold preparation personnel to ensure all steps are followed correctly and the mold is ready for pouring.

6. Describe the different types of steel pouring ladles and their applications.

- Lip-Pour Ladles: Used for pouring molten steel into molds with a top opening.

- Bottom-Pour Ladles: Used for pouring molten steel into molds with a bottom opening, allowing for more precise pouring and reduced turbulence.

- Tundish Ladles: Used in continuous casting operations, where molten steel is poured into a tundish and then flows into the casting mold.

- Vacuum Ladles: Used to degas molten steel by applying a vacuum to remove dissolved gases and improve steel quality.

7. How do you calculate the weight of molten steel in a ladle?

- Measure Ladle Volume: Determine the volume of the ladle using its dimensions or a calibration chart.

- Determine Steel Density: Obtain the density of molten steel for the specific steel grade being poured.

- Calculate Weight: Multiply the ladle volume by the steel density to get the weight of molten steel in the ladle.

- Use Ladle Weighing Systems: Some ladles are equipped with weighing systems that provide real-time weight measurements.

8. Explain the role of solidification in steel casting and how you control it.

- Solidification Process: Solidification occurs as molten steel cools and transforms into a solid state.

- Controlling Solidification Rate: Control the rate of solidification by adjusting pouring temperature, mold design, and cooling conditions.

- Grain Structure: Controlled solidification influences the grain structure of the steel, affecting its mechanical properties.

- Cooling Techniques: Use cooling techniques such as water or air cooling to accelerate solidification and achieve desired properties.

9. Describe the different types of steel casting defects and how you prevent them.

- Shrinkage Cavities: Prevent by optimizing pouring temperatures and solidification rates, and using feeder heads to compensate for volume reduction.

- Gas Entrapment: Prevent by degassing the molten steel, controlling pouring rates, and using vacuum casting techniques.

- Inclusions: Prevent by controlling slag formation, maintaining clean equipment, and using filters or refractories to trap impurities.

- Cracks: Prevent by controlling cooling rates, avoiding thermal shocks, and minimizing stresses during casting and solidification.

- Porosity: Prevent by degassing, controlling solidification rates, and optimizing mold design to prevent gas entrapment.

10. How do you maintain and troubleshoot steel pouring equipment?

- Regular Inspections: Conduct routine inspections to identify potential issues and wear and tear.

- Preventive Maintenance: Follow maintenance schedules for equipment such as ladles, nozzles, and pouring systems.

- Troubleshooting: Diagnose and resolve equipment malfunctions, such as clogged nozzles, leaking ladles, or electrical problems.

- Collaboration: Collaborate with maintenance personnel to ensure equipment is operating at peak efficiency and safety standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Pourer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Pourer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Steel Pourer, you will be responsible for the safe and efficient operation of the steel pouring process in a steel mill. Your key responsibilities will include:

1. Operating pouring equipment

You will be responsible for operating and maintaining the equipment used to pour molten steel from furnaces into molds. This equipment includes, but not limited to: tundishes, nozzles and slide gates.

- Monitoring and adjusting the flow of molten steel

- Ensuring that the molten steel is poured into the molds correctly to produce quality steel products

2. Monitoring and controlling process parameters

You will monitor and control various process parameters to ensure the steel pouring process is carried out safely and efficiently. This includes monitoring:

- Temperature of the molten steel

- Speed and flow rate of the molten steel

- Pressure in the pouring equipment

3. Ensuring safety and environmental compliance

You will be responsible for ensuring that the steel pouring process is carried out in a safe and environmentally compliant manner. This includes:

- Adhering to safety regulations and procedures

- Wearing proper protective gear

- Monitoring and controlling emissions

4. Maintaining a clean and organized work area

You will be responsible for maintaining a clean and organized work area, including:

- Cleaning and maintaining pouring equipment

- Disposing of waste materials properly

- Keeping the work area free of hazards

Interview Tips

To ace the interview for a Steel Pourer position, it is important to prepare thoroughly and highlight your relevant skills and experience. Here are some tips to help you prepare:

1. Research the company and position

Before the interview, take the time to research the company and the specific Steel Pourer position you are applying for. This will give you a better understanding of the company’s culture, values, and the requirements of the role.

- Visit the company’s website and social media pages

- Read industry news and articles about the company

2. Prepare your answers to common interview questions

There are certain interview questions that are commonly asked in Steel Pourer interviews. It is helpful to prepare your answers to these questions in advance so that you can deliver them confidently and concisely during the interview.

- Tell me about your experience operating pouring equipment.

- What are your strategies for ensuring safety and environmental compliance in the steel pouring process?

- How do you maintain a clean and organized work area?

3. Practice your technical skills

In addition to preparing your answers to interview questions, it is also important to practice your technical skills. This includes demonstrating your ability to operate pouring equipment and monitor process parameters. You can practice these skills by working on projects or simulations.

- Volunteer or intern at a steel mill

- Take online courses or workshops on steel pouring

4. Be confident and professional

During the interview, it is important to be confident and professional. Dress appropriately, arrive on time, and make eye contact with the interviewer. Be respectful and answer questions honestly and thoroughly. Your confidence and professionalism will make a positive impression on the interviewer.

- Dress appropriately for the interview.

- Be on time for your interview.

- Make eye contact with the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Steel Pourer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.