Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Steel Tester interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Steel Tester so you can tailor your answers to impress potential employers.

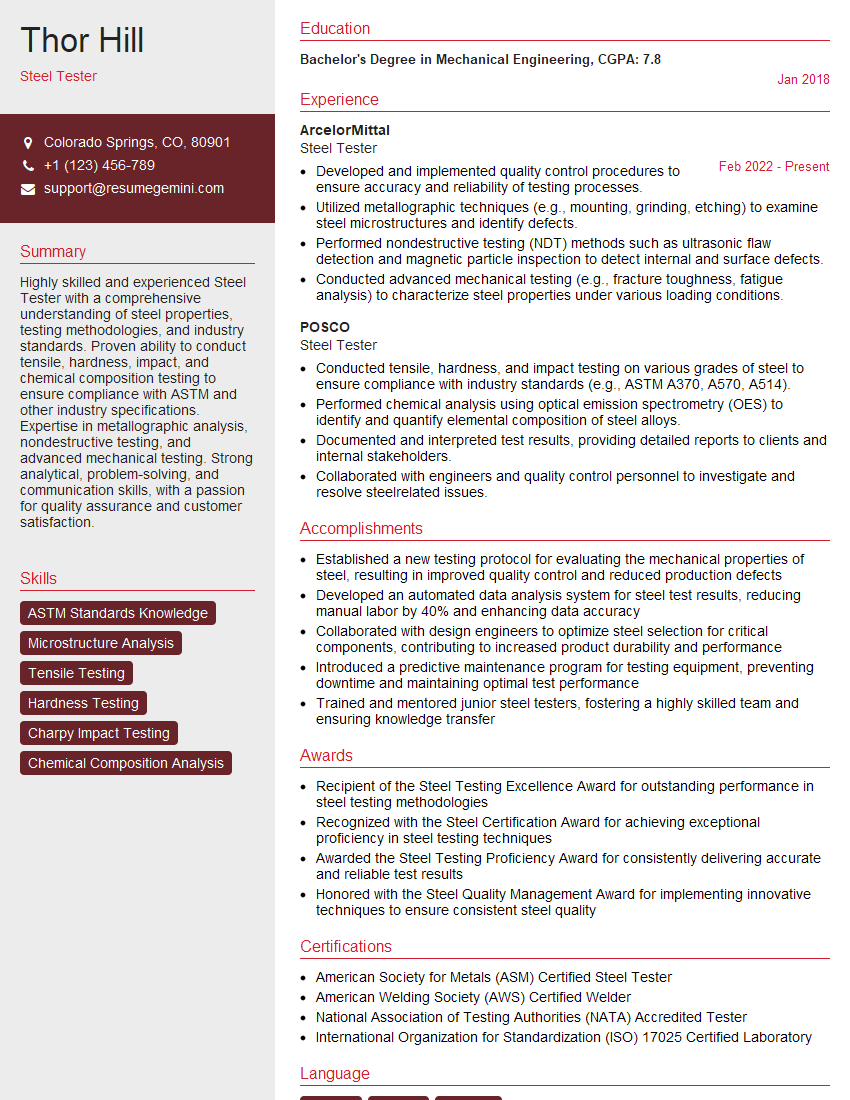

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Tester

1. Which are the main categories of steel?

There are three main categories of steel based on their composition and properties:

- Carbon steels: These steels contain varying amounts of carbon, typically ranging from 0.05% to 1.5%. They are strong, hard, and ductile, and are commonly used for structural applications, such as in buildings and bridges.

- Alloy steels: These steels contain additional elements, such as chromium, nickel, or molybdenum, in addition to carbon. They are stronger and more resistant to wear and corrosion than carbon steels, and are often used in automotive, aerospace, and other demanding applications.

- Stainless steels: These steels contain a high percentage of chromium, which makes them resistant to corrosion and rust. They are commonly used in applications where cleanliness and hygiene are important, such as in cookware, medical equipment, and chemical processing equipment.

2. What are the different types of steel tests?

- Chemical analysis: This test determines the chemical composition of steel, which influences its properties.

- Mechanical testing: This test evaluates the mechanical properties of steel, such as its strength, hardness, and ductility.

- Metallurgical testing: This test examines the microstructure of steel to determine its grain size, inclusions, and other characteristics.

- Non-destructive testing: This test uses various techniques to evaluate the integrity of steel without damaging it, such as ultrasonic, radiographic, and magnetic particle testing.

3. How do you perform a hardness test on steel?

There are several methods for performing a hardness test on steel, including:

- Brinell hardness test: This test uses a hardened steel ball to indent the surface of the steel. The hardness is measured by the diameter of the indentation.

- Vickers hardness test: This test uses a diamond indenter to indent the surface of the steel. The hardness is measured by the diagonal length of the indentation.

- Rockwell hardness test: This test uses a conical diamond indenter or a hardened steel ball to indent the surface of the steel. The hardness is measured by the depth of the indentation.

4. How do you interpret the results of a tensile test?

The results of a tensile test are typically presented in a stress-strain curve. The stress is the force applied to the steel divided by the cross-sectional area of the specimen. The strain is the elongation of the specimen divided by its original length. The yield strength is the stress at which the steel begins to deform plastically. The ultimate tensile strength is the maximum stress that the steel can withstand before it fractures.

5. What are the factors that can affect the properties of steel?

- Chemical composition: The composition of steel, particularly the amount of carbon and other alloying elements, can significantly affect its properties.

- Heat treatment: Heat treatment processes, such as annealing, quenching, and tempering, can alter the microstructure and properties of steel.

- Mechanical processing: Cold working and hot working processes, such as rolling, forging, and drawing, can affect the grain size and mechanical properties of steel.

- Environmental conditions: Exposure to corrosive environments, high temperatures, or other environmental factors can affect the properties of steel.

6. What are the different applications of steel?

Steel is used in a wide variety of applications, including:

- Construction: Steel is used in the construction of buildings, bridges, and other structures.

- Automotive: Steel is used in the production of cars, trucks, and other vehicles.

- Aerospace: Steel is used in the production of aircraft and spacecraft.

- Medical: Steel is used in the production of medical devices and equipment.

- Energy: Steel is used in the production of wind turbines, solar panels, and other energy-related equipment.

7. What are the advantages of using steel?

- Strength: Steel is a very strong and durable material.

- Rigidity: Steel is a rigid material, meaning that it does not deform easily.

- Versatility: Steel can be used in a wide variety of applications.

- Recyclability: Steel is a recyclable material, which makes it environmentally friendly.

8. What are the disadvantages of using steel?

- Cost: Steel can be a relatively expensive material.

- Corrosion: Steel is susceptible to corrosion, especially in humid environments.

- Weight: Steel is a heavy material, which can make it difficult to transport and install.

9. What are the different types of steel finishes?

- Hot-rolled: Hot-rolled steel is produced by rolling steel at high temperatures. It has a rough, scaly surface.

- Cold-rolled: Cold-rolled steel is produced by rolling steel at room temperature. It has a smooth, shiny surface.

- Galvanized: Galvanized steel is coated with a layer of zinc to protect it from corrosion.

- Painted: Painted steel is coated with a layer of paint to protect it from corrosion and to improve its appearance.

10. What are the latest trends in steel technology?

- Advanced high-strength steels: Advanced high-strength steels are being developed to provide higher strength and reduced weight for automotive applications.

- Corrosion-resistant steels: New corrosion-resistant steels are being developed for use in harsh environments, such as offshore oil and gas applications.

- Sustainable steel production: There is a growing trend towards more sustainable steel production methods, such as using recycled materials and reducing energy consumption.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Testers are responsible for ensuring the quality of steel products by conducting a variety of tests and inspections. Their key responsibilities include:

1. Conducting Mechanical Tests

Steel Testers conduct mechanical tests to determine the strength, hardness, and other properties of steel. These tests may include tensile tests, impact tests, and hardness tests.

2. Performing Chemical Analysis

Steel Testers perform chemical analysis to determine the composition of steel. This information is used to ensure that the steel meets the required specifications.

3. Inspecting Steel Products

Steel Testers inspect steel products for defects such as cracks, voids, and surface imperfections. They also check the dimensions and tolerances of the products.

4. Preparing Test Reports

Steel Testers prepare test reports that summarize the results of their tests and inspections. These reports are used by engineers, quality control personnel, and other stakeholders to make decisions about the quality of steel products.

Interview Tips

To ace an interview for a Steel Tester position, candidates should be prepared to discuss their experience and skills in the following areas:

1. Technical Skills

Candidates should be familiar with the various methods used to test and inspect steel. They should also have a strong understanding of the properties of steel and how different factors can affect its quality.

2. Communication Skills

Steel Testers must be able to communicate their findings clearly and concisely to engineers, quality control personnel, and other stakeholders. They should also be able to work effectively as part of a team.

3. Problem-Solving Skills

Steel Testers often encounter problems when testing and inspecting steel products. They must be able to troubleshoot these problems and find solutions that ensure the quality of the products.

4. Attention to Detail

Steel Testers must be able to pay close attention to detail when conducting tests and inspections. They must be able to identify even the smallest defects that could affect the quality of the products.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Steel Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.