Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Steel Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

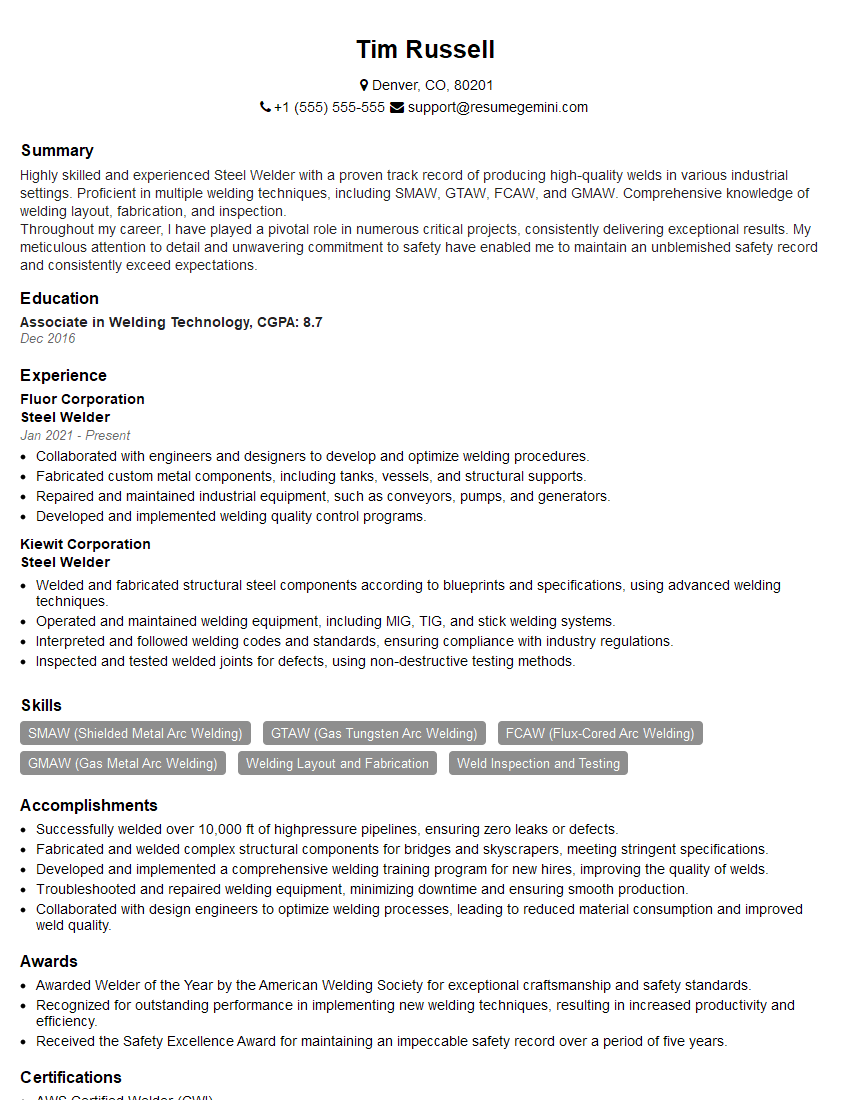

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Welder

1. What are the different types of welding processes you are familiar with?

I am proficient in various welding processes, including:

- Arc welding (e.g., shielded metal arc welding, gas metal arc welding, gas tungsten arc welding)

- Resistance welding

- Laser welding

- Submerged arc welding

- Flux-cored arc welding

2. What are the key parameters that need to be controlled in welding to ensure quality welds?

To ensure high-quality welds, I pay meticulous attention to the following parameters:

- Welding current: Controls the heat input and affects penetration.

- Voltage: Determines the arc length and stability.

- Travel speed: Influences the weld bead size and shape.

- Gas flow rate: Shields the weld pool from contamination.

- Electrode type and diameter: Impacts joint design and weld properties.

- Joint preparation: Clean, properly fitted joints promote good weld quality.

3. How do you ensure that your welds meet industry standards and specifications?

I strictly adhere to the following practices to ensure compliance with industry standards and specifications:

- Qualification testing: Undergo regular testing to demonstrate my welding skills and abilities.

- Visual inspection: Conduct thorough visual inspections of welds to detect any surface defects or imperfections.

- Non-destructive testing: Utilize methods such as radiography, ultrasonic testing, and magnetic particle inspection to evaluate weld integrity.

- Documenting procedures: Maintain detailed records of welding parameters, materials used, and quality control measures.

- Continuous training: Stay up-to-date with industry advancements and best practices through ongoing training and education.

4. What safety precautions do you take when working with welding equipment?

I prioritize safety by adhering to the following precautions:

- Wear appropriate protective gear (e.g., welding helmet, gloves, flame-resistant clothing).

- Ensure proper ventilation to prevent fume inhalation.

- Inspect equipment regularly and maintain it in good condition.

- Store flammable materials safely and avoid working near combustible substances.

- Follow established safety protocols and procedures.

5. Can you describe your experience in welding different types of materials?

I have extensive experience welding various materials, including:

- Steel: Carbon steel, stainless steel, alloy steel

- Aluminum: Alloys such as 6061, 7075

- Titanium: Grades 2, 5, 7

- Copper and its alloys: Bronze, brass

- Nickel-based alloys: Inconel, Monel

6. How do you handle welding in different positions (e.g., overhead, vertical)?

I am proficient in welding in various positions, including:

- Flat: Welding on a horizontal surface.

- Horizontal: Welding on a vertical surface.

- Vertical: Welding in an upward or downward direction.

- Overhead: Welding on a surface above the welder’s head.

I adjust my techniques and equipment to ensure high-quality welds regardless of the position.

7. What are the common welding defects and how do you prevent them?

I am familiar with the following welding defects and take preventive measures to minimize their occurrence:

- Porosity: Trapped gas bubbles; prevented by using proper shielding gas and welding techniques.

- Lack of fusion: Incomplete joining of metal; prevented by ensuring proper joint preparation and welding parameters.

- Cold lap: Overlapping of unmelted metal; prevented by using the correct welding speed and heat input.

- Undercut: Groove melted into the base metal; prevented by controlling travel speed and electrode angle.

- Slag inclusions: Trapped slag; prevented by proper cleaning and using appropriate fluxes.

8. How do you interpret welding symbols and blueprints?

I am proficient in interpreting welding symbols and blueprints to accurately follow welding instructions. I use the following steps:

- Identify the basic weld symbol (e.g., fillet, groove).

- Determine the weld size and shape.

- Specify the weld preparation (e.g., bevel, edge).

- Review the dimensions and tolerances.

- Refer to the notes and specifications for additional information.

9. What are your strengths as a Steel Welder?

My key strengths as a Steel Welder include:

- Proficient in various welding processes and techniques.

- Excellent understanding of welding parameters and their impact on weld quality.

- Exceptional ability to follow welding symbols and blueprints.

- Meticulous attention to detail and commitment to producing high-quality work.

- Strong safety consciousness and adherence to industry standards.

10. What are your career goals as a Steel Welder?

My career goals as a Steel Welder are to:

- Continue developing my skills and expertise in welding technologies.

- Contribute to high-quality welding projects that meet or exceed industry standards.

- Work in a collaborative and challenging environment where I can learn and grow professionally.

- Obtain industry certifications and licenses to enhance my credibility and marketability.

- Advance my career to roles with increased responsibilities and leadership opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Welders are responsible for joining metal components, typically using a welding torch. They must be able to read and interpret blueprints, set up and operate welding equipment, and ensure that welds meet quality standards. Key job responsibilities include:

1. Welding and Fabrication

Welders use a variety of welding techniques to join metal components, including:

- Arc welding

- MIG welding

- TIG welding

- Submerged arc welding

- Spot welding

2. Blueprint Reading and Interpretation

Welders must be able to read and interpret blueprints to understand the design and specifications of the components they are welding. They must be able to identify the types of welds required, the materials being used, and the tolerances that must be met.

3. Equipment Setup and Operation

Welders must be able to set up and operate a variety of welding equipment, including:

- Welding torches

- Power supplies

- Gas regulators

- Welding jigs and fixtures

4. Quality Control

Welders must ensure that their welds meet quality standards. They must be able to inspect welds for defects, such as cracks, porosity, and undercuts. They must also be able to test welds to ensure that they meet strength and durability requirements.

Interview Tips

Preparing for an interview can be daunting, but with the right tips and tricks, you can increase your chances of impressing the interviewer and landing the job. Here are some tips to help you prepare for a steel welder interview:

1. Research the Company and the Position

Before you go to an interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and the skills and experience they are looking for in a steel welder.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as:

- Tell me about your experience as a steel welder.

- What are your strengths and weaknesses as a welder?

- Why are you interested in this position?

- What are your salary expectations?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of an interview shows the interviewer that you are engaged and interested in the position. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

- What is the company’s safety record?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you respect their time and that you are serious about the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Steel Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.