Feeling lost in a sea of interview questions? Landed that dream interview for Steel Wool Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Steel Wool Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

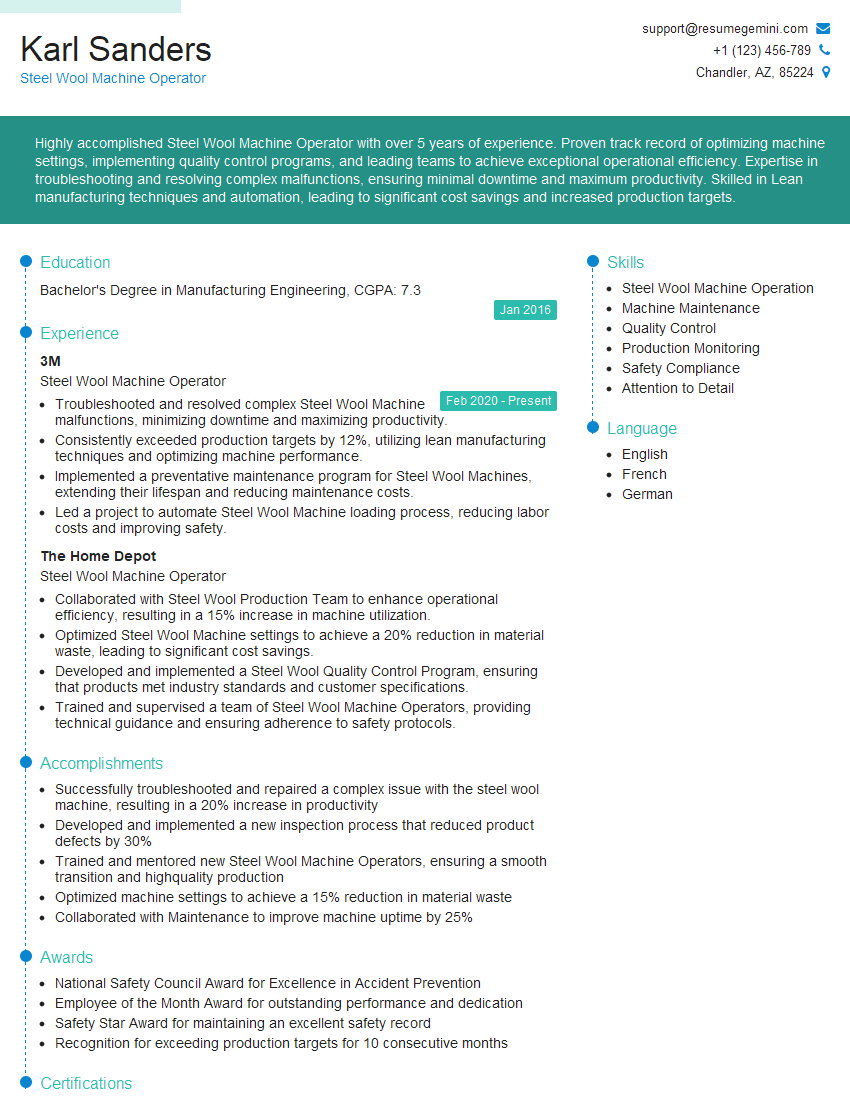

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Wool Machine Operator

1. Describe the process of operating a steel wool machine?

Sure, here is a general overview of the process of operating a steel wool machine:

- Set up the machine: This may involve placing a bale of steel wool on the feed table, attaching the appropriate cutting head, and setting the desired speed and thickness settings.

- Start the machine: Once the machine is set up, it can be started by pressing a button or pulling a lever.

- Monitor the machine: While the machine is running, the operator should monitor it to ensure that it is running smoothly and that the wool is being produced to the desired specifications.

- Stop the machine: Once the desired amount of wool has been produced, the machine can be stopped by pressing a button or pulling a lever.

- Clean the machine: After the machine has been stopped, it should be cleaned to remove any steel wool or debris.

2. What are the safety precautions that must be taken when operating a steel wool machine?

General safety

- Wear appropriate safety gear, including eye protection, gloves, and a dust mask.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is damaged or malfunctioning.

- Be aware of the location of the emergency stop button.

Specific hazards

- Fire: Steel wool is highly flammable, so it is important to keep the work area free of sparks and open flames.

- Cuts: The cutting blades on the machine are sharp, so it is important to be careful when handling them.

- Inhalation: Steel wool dust can be harmful if inhaled, so it is important to wear a dust mask.

3. How do you troubleshoot a steel wool machine that is not producing wool to the desired specifications?

There are several potential reasons why a steel wool machine may not be producing wool to the desired specifications. Some of the most common problems include:

- The cutting head is not sharp enough. If the cutting head is not sharp enough, it will not be able to cut the steel wool cleanly. This can result in wool that is too thick or too thin.

- The machine is not set to the correct speed. The speed of the machine will determine the thickness of the wool. If the machine is set to too high of a speed, the wool will be too thin. If the machine is set to too low of a speed, the wool will be too thick.

- The machine is not feeding the steel wool correctly. If the machine is not feeding the steel wool correctly, it will not be able to produce wool to the desired specifications. This can be caused by a variety of problems, such as a clogged feed chute or a malfunctioning feed motor.

To troubleshoot a steel wool machine that is not producing wool to the desired specifications, the operator should first check the cutting head, the speed setting, and the feed system. If any of these components are not functioning properly, the operator should make the necessary adjustments or repairs.

4. What are the different grades of steel wool and what are they used for?

Steel wool is available in a variety of grades, each with its own unique set of properties and applications.

- Coarse steel wool (grades 0000-000) is the coarsest grade of steel wool and is used for heavy-duty cleaning tasks, such as removing rust and paint.

- Medium steel wool (grades 00-0) is a medium-grade steel wool that is used for general cleaning tasks, such as cleaning pots and pans.

- Fine steel wool (grades 1-2) is a fine-grade steel wool that is used for delicate cleaning tasks, such as cleaning jewelry and electronics.

- Superfine steel wool (grades 3-4) is the finest grade of steel wool and is used for very delicate cleaning tasks, such as cleaning optical lenses.

5. How do you store steel wool safely?

Steel wool should be stored in a cool, dry place away from sources of heat and ignition. It should also be kept out of reach of children and pets.

6. What are some of the common problems that can occur when using a steel wool machine, and how can you prevent them?

Some of the common problems that can occur when using a steel wool machine include:

- The machine can become clogged with steel wool. To prevent this, the operator should regularly clean the machine and remove any built-up steel wool.

- The cutting head can become dull. To prevent this, the operator should regularly sharpen the cutting head.

- The machine can overheat. To prevent this, the operator should ensure that the machine is well-ventilated and that it is not overloaded.

7. What are the maintenance requirements for a steel wool machine?

The maintenance requirements for a steel wool machine will vary depending on the specific make and model of the machine. However, some general maintenance tasks that should be performed on a regular basis include:

- Cleaning the machine to remove any built-up steel wool

- Sharpening the cutting head

- Lubricating the machine’s moving parts

- Inspecting the machine for any damage or wear

8. How do you dispose of steel wool safely?

Steel wool should be disposed of in accordance with local regulations. In general, steel wool can be disposed of in a landfill or recycled as scrap metal.

9. What are the advantages and disadvantages of using steel wool?

Advantages

- Steel wool is a versatile material that can be used for a variety of cleaning tasks.

- Steel wool is relatively inexpensive.

- Steel wool is biodegradable.

Disadvantages

- Steel wool can be sharp and can cause cuts if not handled carefully.

- Steel wool can rust if not stored properly.

10. What are some of the alternative materials that can be used for cleaning tasks instead of steel wool?

Some of the alternative materials that can be used for cleaning tasks instead of steel wool include:

- Nylon scouring pads

- Plastic scouring pads

- Sponge scouring pads

- Microfiber cloths

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Wool Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Wool Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Wool Machine Operators are responsible for operating and maintaining steel wool machines, which produce steel wool used in a variety of applications, including cleaning, polishing, and manufacturing.

1. Set up and operate steel wool machines

intro paragraph

- Load raw materials into the machine

- Adjust machine settings to produce the desired grade of steel wool

2. Monitor and maintain steel wool machines

intro paragraph

- Monitor machine operation to ensure that it is producing steel wool to the desired specifications

- Perform regular maintenance on the machine, including cleaning, lubrication, and repairs

3. Inspect and package steel wool

intro paragraph

- Inspect steel wool to ensure that it meets quality standards

- Package steel wool into containers for storage or shipment

4. Maintain a clean and safe work area

intro paragraph

- Clean up spills and debris from the work area

- Follow all safety regulations and procedures

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of success. Here are a few tips to help you prepare for your Steel Wool Machine Operator interview:

1. Research the company and the position

Take some time to learn about the company you are applying to and the specific position you are interested in. This will help you understand the company’s culture, values, and what they are looking for in a Steel Wool Machine Operator.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Prepare questions to ask the interviewer

Asking thoughtful questions at the end of an interview shows that you are engaged and interested in the position. Prepare a few questions that you would like to ask the interviewer about the company, the position, or the industry.

4. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally for your interview. Arrive on time for your interview and be prepared to answer questions about your experience and qualifications.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Steel Wool Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.