Are you gearing up for a career in Steelworker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Steelworker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

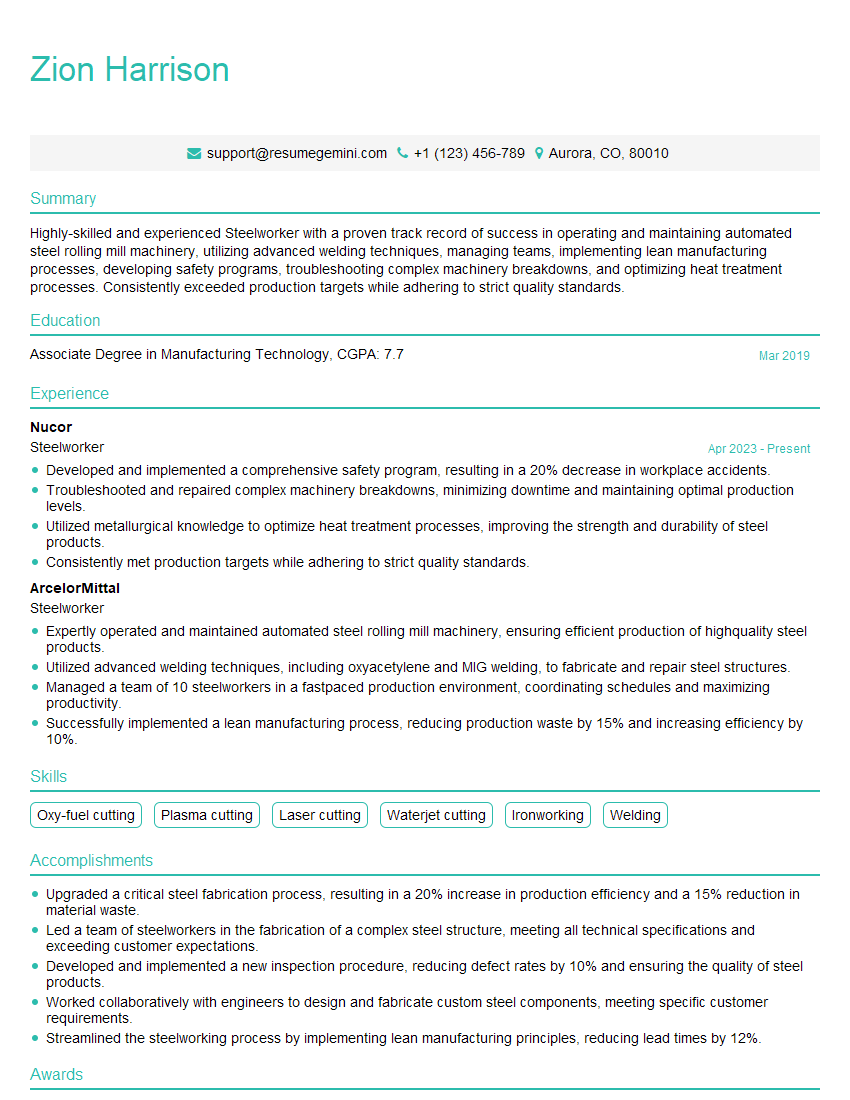

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steelworker

1. How would you interpret the blueprint drawings for steel fabrication?

I would first identify the different symbols, lines, and notations used to represent the various elements of the structure. I would then examine the overall layout of the drawing to understand the general arrangement of the steel components. Next, I would focus on the details of each component, including the dimensions, shape, and any special requirements. I would also make sure to note the welding symbols and any other relevant information.

2. What are the different types of steel fabrication equipment and their uses?

Cutting Equipment

- Plasma cutter: Uses a plasma torch to cut metal by melting it with a high-temperature plasma.

- Laser cutter: Uses a high-powered laser to cut metal by vaporizing it.

- Waterjet cutter: Uses a high-pressure stream of water mixed with abrasive particles to cut metal.

Forming Equipment

- Press brake: Used to bend metal into various shapes.

- Rolling mill: Used to reduce the thickness of metal by passing it through a series of rollers.

- Forging press: Used to shape metal by hammering or pressing it into a mold.

Welding Equipment

- Arc welder: Uses an electric arc to create heat that melts the metal and joins it together.

- MIG welder: Uses a shielding gas to protect the weld from the atmosphere.

- TIG welder: Uses a tungsten electrode to create an arc that melts the metal.

3. How do you ensure the accuracy and quality of fabricated steel components?

I would use a variety of methods to ensure accuracy and quality, including:

- Measuring and inspecting the raw materials before fabrication.

- Using precision tools and equipment to cut and shape the steel.

- Following the blueprint drawings and specifications precisely.

- Conducting regular inspections throughout the fabrication process.

- Testing the finished product to ensure it meets the required standards.

4. What safety precautions must be taken when working with steel fabrication equipment?

I would always wear appropriate personal protective equipment, including a hard hat, safety glasses, gloves, and earplugs. I would also follow all safety protocols and procedures for the equipment being used. This includes staying clear of moving parts, never putting my hands near the cutting or welding zone, and never operating equipment without proper training.

5. What experience do you have with welding different types of metals?

I have experience welding a variety of metals, including:

- Mild steel

- Stainless steel

- Aluminum

- Cast iron

- Copper

I am proficient in various welding processes, including:

- Arc welding

- MIG welding

- TIG welding

- Oxy-acetylene welding

6. What is your experience with structural steel erection?

I have experience erecting structural steel for a variety of projects, including:

- Commercial buildings

- Industrial buildings

- Bridges

- Power plants

I am familiar with the different types of structural steel components and how they are assembled. I am also experienced in using cranes and other equipment to lift and position steel members.

7. What are the different types of welding joints and when are they used?

The most common types of welding joints are:

- Butt joint: Used to join two pieces of metal together end-to-end.

- Edge joint: Used to join two pieces of metal together along their edges.

- T-joint: Used to join two pieces of metal together at a right angle.

- Corner joint: Used to join two pieces of metal together at a 90-degree angle.

- Lap joint: Used to join two pieces of metal together by overlapping them.

The type of welding joint used depends on the specific application. Factors to consider include the strength required, the type of metal being joined, and the thickness of the metal.

8. What are the different types of welding defects and how can they be prevented?

Common welding defects include:

- Cracks: Caused by excessive heat, improper welding technique, or poor joint design.

- Porosity: Caused by entrapped gas in the weld pool.

- Slag inclusions: Caused by flux or other impurities in the weld pool.

- Undercutting: Caused by excessive heat or improper welding technique.

- Cold lap: Caused by insufficient fusion between two pieces of metal.

Welding defects can be prevented by using proper welding techniques, following the manufacturer’s instructions for the welding equipment, and inspecting the weld as it is being made.

9. What is the difference between hot rolled and cold rolled steel?

Hot rolled steel is produced by rolling steel at high temperatures, above 926 degrees Celsius (1700 degrees Fahrenheit). This process makes the steel stronger and more ductile. Cold rolled steel is produced by rolling steel at room temperature. This process makes the steel harder and stronger than hot rolled steel, but also more brittle.

10. What is the difference between carbon steel and stainless steel?

Carbon steel is a type of steel that contains a small amount of carbon, typically less than 1%. This carbon content makes carbon steel harder and stronger than pure iron, but also more brittle. Stainless steel is a type of steel that contains a higher amount of carbon, typically between 10% and 30%. This carbon content makes stainless steel harder and stronger than carbon steel, and also more resistant to corrosion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steelworker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steelworker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steelworkers are responsible for a variety of tasks related to the production and fabrication of steel products. These responsibilities may vary depending on the specific industry and job requirements, but some of the most common include:

1. Steel Fabrication

Steelworkers fabricate steel products by cutting, bending, welding, and assembling various steel components. They use specialized tools and equipment to create a wide range of products, such as structural beams, pipes, tanks, and machinery.

- Cutting steel plates, beams, and other components to specified dimensions using oxy-fuel torches, plasma cutters, or saws.

- Bending steel components to create curves, angles, and other shapes using press brakes, rollers, or hand tools.

- Welding steel components together using various welding techniques, such as arc welding, MIG welding, or TIG welding.

- Assembling steel structures, such as bridges, buildings, and ships, by connecting and securing steel components with bolts, rivets, or other fasteners.

2. Steel Erection

Steelworkers erect steel structures by hoisting and positioning steel components into place using cranes and other heavy equipment. They must ensure that the structures are properly aligned and secured to meet safety and building codes.

- Rigging and hoisting steel beams, columns, and other components using cranes and other lifting equipment.

- Positioning and aligning steel components according to blueprints and specifications.

- Bolting, welding, or riveting steel components together to create a strong and stable structure.

- Inspecting steel structures to ensure they meet safety and building code requirements.

3. Steel Maintenance and Repair

Steelworkers perform maintenance and repair work on steel structures to ensure their safety and integrity. They inspect steel components for damage or wear, and repair or replace damaged parts as needed.

- Inspecting steel structures for cracks, corrosion, or other damage using visual inspections, ultrasonic testing, or other non-destructive testing methods.

- Repairing or replacing damaged steel components by welding, bolting, or riveting new or refurbished parts.

- Performing preventative maintenance tasks, such as cleaning, painting, and lubricating steel components, to extend their lifespan.

- Following safety protocols and using appropriate personal protective equipment (PPE) while performing maintenance and repair work.

4. Quality Control

Steelworkers play a crucial role in ensuring the quality of steel products and structures. They inspect raw materials, finished products, and work in progress to identify and correct any defects or deviations from specifications.

- Inspecting steel materials and components for defects, such as cracks, inclusions, or surface imperfections.

- Verifying that finished steel products meet customer specifications and industry standards.

- Conducting non-destructive testing, such as ultrasonic testing or radiography, to evaluate the integrity of steel components.

- Maintaining quality control records and reporting any non-conformances to management.

Interview Tips

Preparing well for a steelworker interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific steelworker position you are applying for. This will give you a good understanding of the company’s culture, values, and the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends and technologies in the steel industry.

- Review the job description carefully to identify the key responsibilities and qualifications required for the position.

2. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the steelworker position. This includes your technical abilities, such as welding, fabrication, and quality control, as well as your safety knowledge and experience working in a construction or industrial setting.

- Quantify your accomplishments whenever possible. For example, instead of saying “I have experience in welding,” you could say “I have over 5 years of experience in welding, and I have successfully completed over 100 welding projects.”

- Be prepared to discuss your experience with specific steelworking techniques and equipment.

- Emphasize your safety consciousness and your commitment to following safety protocols.

3. Prepare for Common Interview Questions

There are some common interview questions that you are likely to be asked in a steelworker interview. It is helpful to prepare answers to these questions in advance so that you can deliver confident and well-thought-out responses.

- Tell me about your experience in welding and fabrication.

- What is your knowledge of steel materials and their properties?

- How do you ensure the quality of your work?

- What safety precautions do you take when working with steel?

- Why are you interested in working for our company?

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the company, the position, and the industry. This shows that you are interested in the job and that you are eager to learn more. Some good questions to ask include:

- What are the biggest challenges facing the steel industry today?

- What are the growth prospects for the steelworker position within your company?

- What is the company’s safety record?

- What are the opportunities for professional development and training?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Steelworker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!