Are you gearing up for a career in Stem Roller or Crusher Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Stem Roller or Crusher Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

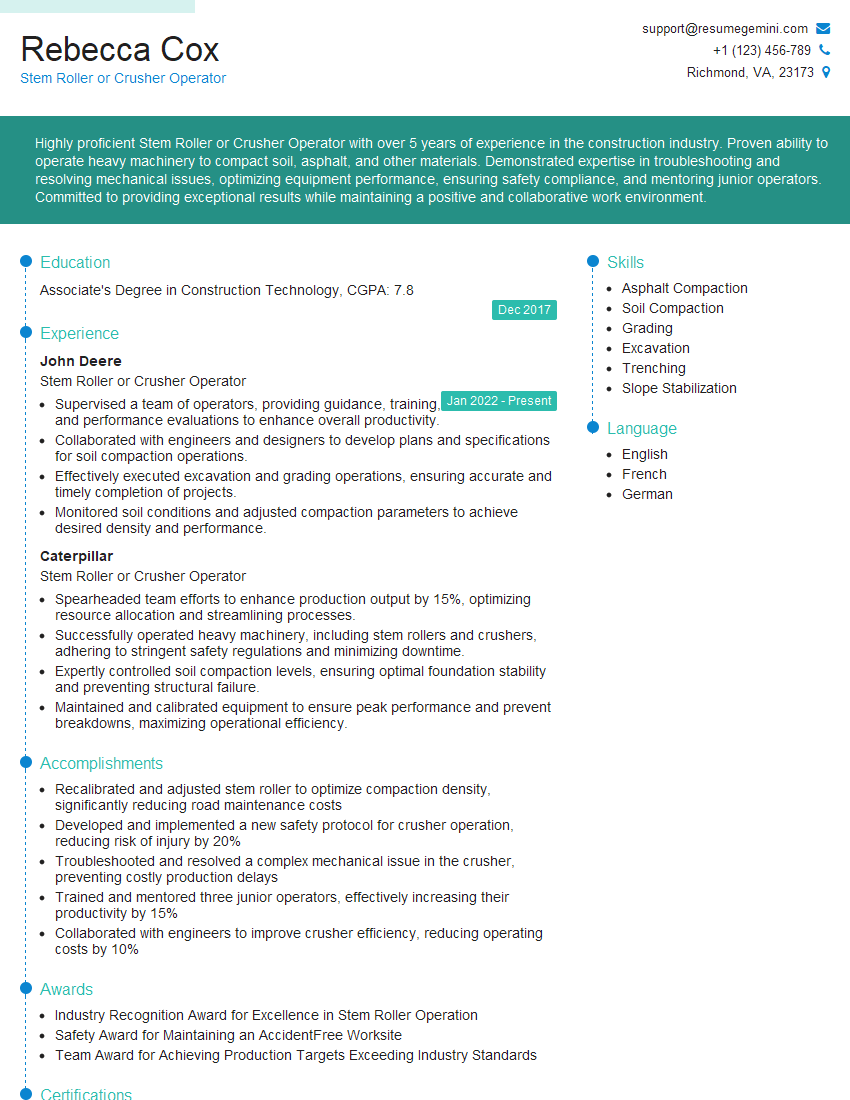

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stem Roller or Crusher Operator

1. Describe the process of operating a stem roller or crusher operator.

The process of operating a stem roller or crusher operator typically involves the following steps:

- Inspect the equipment to ensure that it is in good working order.

- Start the equipment and allow it to warm up.

- Position the equipment over the material to be crushed or rolled.

- Operate the equipment to crush or roll the material to the desired size or consistency.

- Monitor the equipment during operation to ensure that it is operating properly and that the material is being processed correctly.

- Shut down the equipment and clean it after use.

2. What are the different types of stem rollers or crushers?

There are different types of stem rollers and crushers, including:

- Single-drum rollers

- Double-drum rollers

- Pneumatic-tired rollers

- Vibratory rollers

- Jaw crushers

- Gyratory crushers

- Impact crushers

3. What are the safety precautions that must be taken when operating a stem roller or crusher operator?

The safety precautions that must be taken when operating a stem roller or crusher operator include:

- Wear appropriate personal protective equipment, such as safety glasses, gloves, and a hard hat.

- Be aware of your surroundings and keep a safe distance from other people and objects.

- Never operate the equipment under the influence of alcohol or drugs.

- Follow all manufacturer’s instructions for safe operation.

- Be aware of the potential hazards associated with the equipment, such as pinch points, rotating parts, and hot surfaces.

4. What are the common problems that can occur when operating a stem roller or crusher operator?

The common problems that can occur when operating a stem roller or crusher operator include:

- The equipment may not start.

- The equipment may not be able to crush or roll the material to the desired size or consistency.

- The equipment may overheat.

- The equipment may leak oil or hydraulic fluid.

- The equipment may vibrate excessively.

5. How do you troubleshoot and repair common problems that can occur when operating a stem roller or crusher operator?

To troubleshoot and repair common problems that can occur when operating a stem roller or crusher operator, you can follow these steps:

- Identify the problem.

- Refer to the manufacturer’s instructions for troubleshooting and repair procedures.

- Follow the manufacturer’s instructions carefully.

- If you are unable to resolve the problem, contact a qualified mechanic.

6. What are the different types of materials that can be crushed or rolled using a stem roller or crusher operator?

The different types of materials that can be crushed or rolled using a stem roller or crusher operator include:

- Soil

- Asphalt

- Concrete

- Rock

- Coal

- Ore

7. What are the different applications for stem rollers or crushers?

Stem rollers and crushers have a variety of applications, including:

- Road construction

- Building construction

- Mining

- Recycling

- Agriculture

8. What are the advantages of using a stem roller or crusher operator?

The advantages of using a stem roller or crusher operator include:

- Increased productivity

- Improved quality

- Reduced costs

- Enhanced safety

9. What are the disadvantages of using a stem roller or crusher operator?

The disadvantages of using a stem roller or crusher operator include:

- High initial cost

- Regular maintenance and repair costs

- Potential for accidents

- Noise pollution

10. What are the future trends in the stem roller or crusher operator industry?

The future trends in the stem roller or crusher operator industry include:

- Increased automation

- Increased use of sustainable materials

- Development of new and innovative technologies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stem Roller or Crusher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stem Roller or Crusher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stem Rollers or Crusher Operators are pivotal to the construction, mining, and waste management industries. Their responsibilities encompass:

1. Equipment Operation

Dexterously operating and maintaining stem rollers or crushers to prepare surfaces, compact materials, or break down rocks and debris.

- Setting up and calibrating equipment for optimal performance

- Ensuring smooth operation and efficiency of equipment

2. Material Handling

Managing and handling various materials, such as soil, gravel, or waste, during the processing or compaction operations.

- Loading, transporting, and unloading materials as required

- Monitoring material flow and making adjustments to optimize operations

3. Safety and Compliance

Upholding strict safety protocols and adhering to industry regulations to ensure a safe work environment.

- Complying with safety procedures and using appropriate personal protective equipment (PPE)

- Identifying and reporting potential hazards to prevent accidents

4. Maintenance and Troubleshooting

Performing routine maintenance and repairs on equipment to maintain optimal functioning and troubleshoot any operational issues.

- Monitoring equipment performance and detecting early signs of wear or damage

- Executing necessary repairs and adjustments to keep equipment in good working condition

Interview Tips

To ace the interview for a Stem Roller or Crusher Operator position, candidates should:

1. Research the Industry and Company

Demonstrate a thorough understanding of the industry, the company’s operations, and the specific role you are applying for.

- Review industry publications and websites

- Research the company’s website and social media pages

2. Highlight Relevant Experience and Skills

Emphasize your previous experience in operating heavy equipment and handling materials. Highlight any skills or certifications that are relevant to the job.

- Quantify your accomplishments using specific metrics

- Use action verbs to describe your responsibilities

3. Showcase Safety Mindset and Attention to Detail

Convey your strong commitment to safety and your keen attention to detail. Employers prioritize safety in these roles.

- Describe your experience with safety protocols and PPE

- Provide examples of how you have identified and resolved potential safety issues

4. Prepare for Common Interview Questions

- Tell me about your experience operating stem rollers or crushers.

- Describe your safety protocols and how you ensure compliance.

- How do you handle equipment maintenance and troubleshooting?

- What are some of the challenges you have faced in previous roles?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stem Roller or Crusher Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!