Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stencil Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

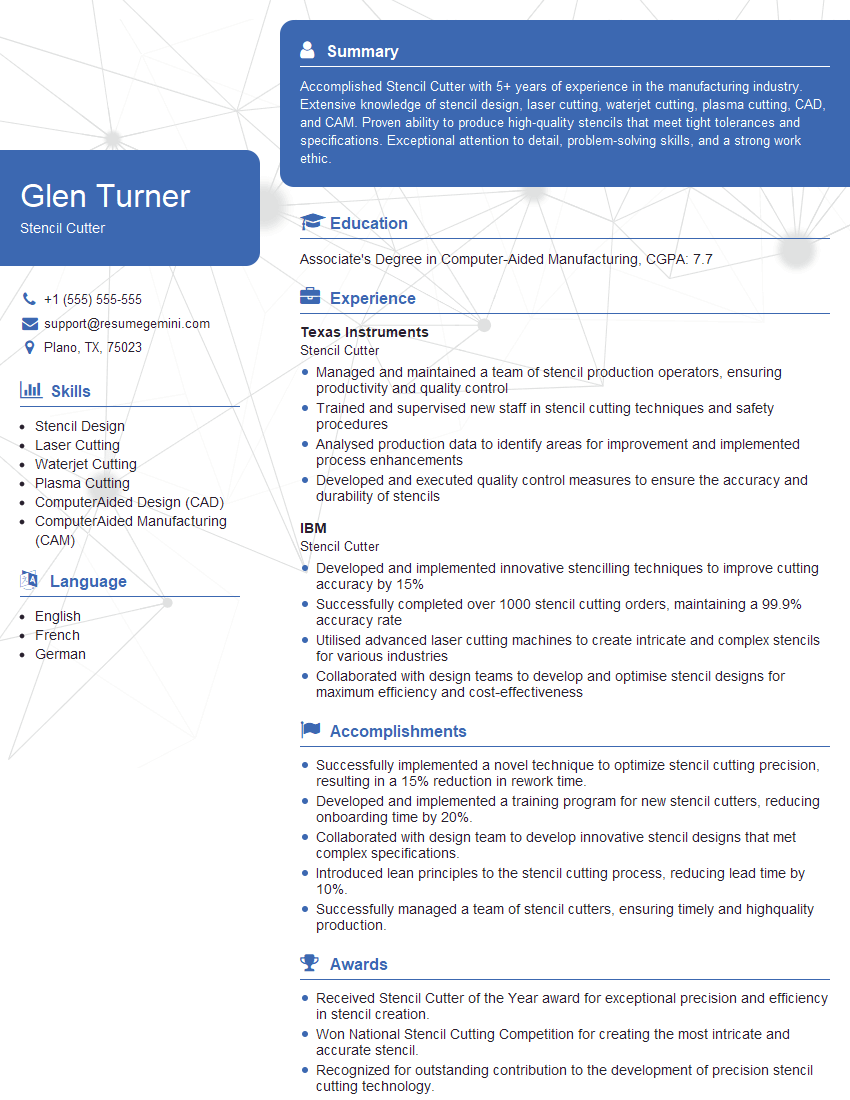

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stencil Cutter

1. Explain the process of creating a stencil using a vinyl cutter?

The process of creating a stencil using a vinyl cutter involves several steps:

- Design Creation: Create the stencil design using software like Adobe Illustrator or CorelDRAW.

- Material Selection: Choose the appropriate vinyl material based on the stencil’s intended use and durability.

- Vinyl Cutting: Load the vinyl material into the vinyl cutter and set the cutting parameters according to the material thickness and design complexity.

- Weeding: Remove the excess vinyl around the stencil design using a weeding tool.

- Transfer: Transfer the stencil to the desired surface using transfer tape or application fluid.

2. What are the different types of vinyl materials available for stencil cutting?

Types of Vinyl Materials:

- Calendared Vinyl: Economical, durable, and suitable for indoor applications.

- Cast Vinyl: Higher quality, more flexible, and ideal for outdoor use.

- Adhesive Vinyl: Has a self-adhesive backing, making it easy to apply to various surfaces.

- Heat-Transfer Vinyl: Requires a heat press to transfer the design onto fabrics.

Factors to Consider:

- Intended use (indoor/outdoor, temporary/permanent)

- Surface compatibility

- Durability and longevity

- Cost and availability

3. Describe the techniques used to ensure precision and accuracy in stencil cutting?

Techniques for Precision and Accuracy:

- Proper Design: Create a clear and detailed design with precise dimensions.

- Material Alignment: Ensure the vinyl material is aligned correctly with the cutting surface.

- Blade Selection: Choose the appropriate blade type and sharpness for the material being cut.

- Cutting Parameters: Set the correct cutting speed, pressure, and depth based on material thickness.

- Test Cuts: Perform test cuts on scrap material to adjust settings and minimize errors.

4. What are the common mistakes to avoid when stencil cutting?

Common Mistakes to Avoid:

- Improper Material Selection: Choosing the wrong vinyl material can affect durability and application.

- Inaccurate Design: Designing a stencil with errors or blurry lines can lead to imprecise cuts.

- Incorrect Cutting Parameters: Using inappropriate cutting settings can damage the material or produce uneven cuts.

- Lack of Weeding Accuracy: Failing to remove excess vinyl cleanly can result in unwanted material on the stencil.

- Poor Transfer: Incorrect application techniques can cause the stencil to shift or not adhere properly to the surface.

5. How do you troubleshoot common issues that arise during stencil cutting?

Troubleshooting Common Issues:

- Material Tearing: Adjust cutting pressure, reduce cutting speed, or use a sharper blade.

- Uneven Cuts: Check if the blade is dull or damaged, adjust the cutting parameters, or ensure proper material alignment.

- Stencil Not Adhering: Clean the surface, use the correct type of transfer tape or fluid, and apply pressure evenly.

- Incorrect Design: Re-design the stencil with clear lines and appropriate dimensions.

- Vinyl Curls: Use a heat gun or hair dryer to gently apply heat to the vinyl, making it more pliable.

6. Describe the safety precautions that should be taken when operating a vinyl cutter?

Safety Precautions:

- Wear Protective Gear: Safety glasses and gloves are essential to protect against blade injuries or material debris.

- Proper Ventilation: Ensure adequate ventilation to remove fumes or dust produced during cutting.

- Regular Maintenance: Keep the cutter clean and well-maintained to prevent malfunction or accidents.

- Blade Handling: Handle blades with care, store them properly, and dispose of them safely.

- Electrical Safety: Ensure the cutter is properly grounded, use surge protectors, and avoid working with wet hands.

7. How do you maintain and calibrate a vinyl cutter for optimal performance?

Maintenance and Calibration:

- Regular Cleaning: Remove dust and debris from the cutter surface, blade, and rollers.

- Blade Maintenance: Sharpen or replace the blade as needed to maintain cutting precision.

- Roller Adjustment: Adjust the rollers to ensure smooth material feeding and prevent slipping.

- Calibration: Calibrate the cutter to maintain accurate cutting dimensions using calibration tools or software.

- Firmware Updates: Check for and install firmware updates to improve cutter functionality and address potential issues.

8. What techniques do you use to optimize the cutting process for different materials?

Material Optimization Techniques:

- Material Profiling: Determine the specific properties of the material (thickness, hardness, etc.) to select the appropriate cutting parameters.

- Blade Selection: Choose the blade type and sharpness that best suits the material being cut.

- Cutting Speed and Pressure: Adjust the cutting parameters based on material thickness and resistance.

- Test Cuts: Conduct test cuts on scrap material to fine-tune the settings for optimal results.

- Material Support: Use backing materials or supports to ensure the material is stable and flat during cutting.

9. How do you ensure the quality and consistency of your stencil production?

Quality Control Measures:

- Design Verification: Review designs carefully before cutting to ensure accuracy and completeness.

- Material Inspection: Check the vinyl material for defects or damage before loading it into the cutter.

- Test Cuts: Perform test cuts on scrap material to verify cutting parameters and material compatibility.

- Visual Inspection: Examine the cut stencils for any errors, imperfections, or deviations from the design.

- Customer Feedback: Regularly gather feedback from customers to identify areas for improvement and maintain high standards.

10. How do you stay updated with the latest advancements in stencil cutting technology and industry best practices?

Continued Learning and Development:

- Industry Publications: Subscribe to trade magazines and industry newsletters to stay informed about new technologies and techniques.

- Online Resources: Utilize online forums, blogs, and technical articles to expand knowledge and learn from others.

- Trade Shows and Conferences: Attend industry events to network with professionals, learn about new products, and gain insights into best practices.

- Manufacturer Training: Participate in training programs offered by vinyl cutter manufacturers to enhance skills and learn about new equipment.

- Mentorship: Seek mentorship from experienced professionals in the field to gain valuable guidance and learn from their expertise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stencil Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stencil Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Stencil Cutter

A Stencil Cutter is responsible for the production of stencils, which are used in various applications such as painting, decorating, and manufacturing. Key responsibilities include:

1. Stencil Design and Creation

Design and create stencils according to customer specifications or in-house designs.

- Understand and interpret customer requirements or design specifications.

- Use specialized software or manual techniques to create precise and accurate stencil designs.

2. Material Selection and Preparation

Select and prepare materials for stencil production, such as plastic, metal, and paper.

- Choose materials that meet the requirements of the stencil design and intended application.

- Prepare materials by cutting, shaping, and cleaning to ensure proper fit and functionality.

3. Stencil Cutting and Finishing

Use specialized cutting tools and techniques to cut stencils according to design specifications.

- Operate CNC (Computer Numerical Control) machines or manual cutters to create precise and intricate cuts.

- Ensure stencils meet quality standards in terms of accuracy, precision, and durability.

4. Quality Control and Maintenance

Inspect and ensure the quality of stencils before delivery to customers or internal departments.

- Check stencils for any defects, inconsistencies, or errors.

- Perform routine maintenance on cutting equipment to ensure optimal performance and accuracy.

Interview Preparation Tips for Stencil Cutter Candidates

To ace an interview for a Stencil Cutter position, it’s crucial to prepare thoroughly and demonstrate your skills and knowledge. Here are some tips:

1. Research the Company and Role

Gather information about the company, their products or services, and the specific responsibilities of the Stencil Cutter role. This shows that you’re genuinely interested in the position and have taken the time to understand the company’s needs.

2. Highlight Your Technical Skills

Emphasize your technical skills and expertise in stencil design, material preparation, and cutting techniques. Provide specific examples of projects you’ve worked on and the techniques you used. Quantify your results whenever possible, using metrics like accuracy, efficiency, and production volume.

3. Showcase Your Attention to Detail

Stencil cutting requires a high level of precision and attention to detail. Highlight your ability to produce consistent, high-quality stencils that meet customer specifications. Describe your quality control processes and how you ensure accuracy in your work.

4. Prepare for Situational Questions

Interviewers may ask situational questions to assess your problem-solving and decision-making skills. Consider scenarios related to material selection, design challenges, or quality control issues. Prepare answers that demonstrate your analytical thinking, adaptability, and customer-centric approach.

5. Practice Common Interview Questions

Practice answering common interview questions, such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses.” Prepare concise, well-thought-out answers that highlight your relevant skills and experience.

6. Bring a Portfolio (Optional)

If possible, prepare a portfolio showcasing samples of your stencil work or design portfolio. This provides tangible evidence of your skills and can help you stand out from other candidates.

Next Step:

Now that you’re armed with the knowledge of Stencil Cutter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Stencil Cutter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini