Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stencil Printer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

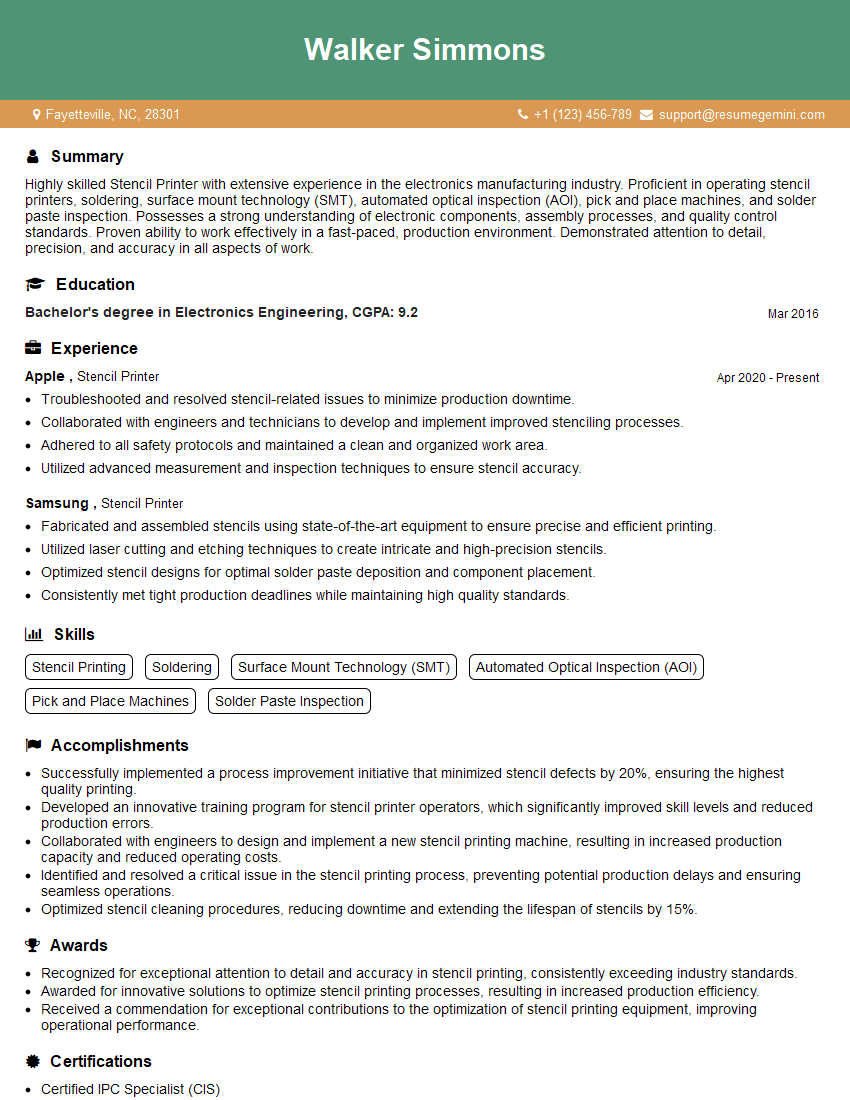

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stencil Printer

1. Explain the basic principles of stencil printing and its importance in electronics manufacturing?

- Stencil printing is a highly accurate and efficient method of applying solder paste to printed circuit boards (PCBs).

- It involves using a metal stencil with apertures cut to the size and shape of the solder pads on the PCB.

- The stencil is placed over the PCB, and solder paste is then applied through the apertures using a squeegee.

- The solder paste is then reflowed, which melts the solder and forms the solder joints.

2. Describe the different types of stencil printers and their advantages and disadvantages?

Flatbed stencil printers

- Flatbed stencil printers are the most common type of stencil printer.

- They are typically used for low- to medium-volume production runs.

- Advantages: low cost, easy to operate, and can print on a wide variety of substrates.

- Disadvantages: slower than other types of stencil printers and can be less accurate.

Cylinder stencil printers

- Cylinder stencil printers are used for high-volume production runs.

- They are faster and more accurate than flatbed stencil printers, but they are also more expensive.

- Advantages: high speed, high accuracy, and can print on a wide variety of substrates.

- Disadvantages: expensive, more complex to operate, and can be less versatile than flatbed stencil printers.

Hybrid stencil printers

- Hybrid stencil printers combine the features of flatbed and cylinder stencil printers.

- They are typically used for medium- to high-volume production runs.

- Advantages: faster than flatbed stencil printers, more accurate than cylinder stencil printers, and can print on a wide variety of substrates.

- Disadvantages: more expensive than flatbed stencil printers, more complex to operate, and can be less versatile than flatbed stencil printers.

3. What are the key factors to consider when selecting a stencil printer?

- The type of PCBs you will be printing

- The volume of PCBs you will be printing

- The accuracy requirements of your PCBs

- The budget you have available

- The available floor space

4. How do you maintain a stencil printer?

- Regularly clean the stencil and the squeegee.

- Inspect the stencil for any damage and replace it if necessary.

- Calibrate the stencil printer regularly.

- Follow the manufacturer’s maintenance instructions.

5. What are the common problems that can occur with stencil printing and how do you troubleshoot them?

- Bridging: This occurs when solder paste bridges between two or more solder pads.

- Solder balling: This occurs when solder paste forms small balls on the PCB.

- Tombstoning: This occurs when a component is not properly soldered to the PCB and stands up on end.

- Headaches: This occurs when a component is not properly soldered to the PCB and falls off.

6. What are the latest trends in stencil printing?

- The use of laser-cut stencils

- The use of automated optical inspection (AOI) to inspect solder joints

- The use of lead-free solder paste

7. What are some of the challenges that you have faced in your previous role as a stencil printer?

- Printing on a variety of different types of PCBs

- Meeting the tight accuracy requirements of our customers

- Troubleshooting and resolving printing problems

8. What are your strengths and weaknesses as a stencil printer?

Strengths:

- I am a highly skilled and experienced stencil printer.

- I have a strong understanding of the principles of stencil printing and the different types of stencil printers.

- I am able to produce high-quality solder joints that meet the tightest accuracy requirements.

- I am a team player and I am always willing to help others.

Weaknesses:

- I am not as experienced with some of the latest trends in stencil printing, such as the use of laser-cut stencils and AOI.

- I am sometimes too focused on the details and I can lose sight of the big picture.

9. Why are you interested in this position?

- I am interested in this position because I am looking for a new challenge and I believe that my skills and experience would be a valuable asset to your company.

- I am also interested in learning more about the latest trends in stencil printing and I believe that this position would provide me with the opportunity to do so.

10. What are your salary expectations?

- My salary expectations are based on my skills and experience, as well as the industry average for similar positions.

- I am open to negotiation and I am willing to work with you to find a salary that is fair and reasonable for both parties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stencil Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stencil Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stencil Printer bears the responsibility of ensuring that the production line runs smoothly and efficiently by operating and maintaining stencil printing equipment. The key job responsibilities typically include:

1. Setup and Operation

A Stencil Printer is required to set up, calibrate, and operate stencil printing equipment as per the established procedures.

2. Quality Control

Monitoring the printing process to ensure the quality of printed circuit boards (PCBs) is of utmost importance. This involves inspecting PCBs for defects and taking corrective actions as necessary.

3. Maintenance and Troubleshooting

Maintaining stencil printing equipment in optimal condition is another key responsibility. This includes cleaning, lubricating, and performing minor repairs. Troubleshooting and resolving equipment malfunctions are also part of the job.

4. Production Support

A Stencil Printer often assists other production personnel in various tasks related to PCB assembly. This can include material handling, inventory management, and providing technical support.

Interview Tips

To increase the chances of acing a Stencil Printer interview, candidates should keep the following tips in mind:

1. Research the Company and Position

Familiarizing yourself with the company’s culture, products, and specific requirements of the Stencil Printer role demonstrates your interest and enthusiasm for the opportunity.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in stencil printing techniques, quality control procedures, and equipment maintenance. Quantifying your accomplishments with specific examples will make your application stand out.

3. Prepare for Technical Questions

Brush up on your knowledge of stencil printing equipment, process parameters, and troubleshooting techniques. Anticipate questions related to stencil design, solder paste application, and PCB inspection criteria.

4. Show Your Teamwork and Communication Skills

PCB assembly typically involves working in a team environment. Highlight your ability to communicate effectively with colleagues, supervisors, and customers. Emphasize your willingness to collaborate and contribute to the team’s success.

5. Practice Common Interview Questions

Prepare for general interview questions such as “Tell me about yourself” and “Why are you interested in this position?” Tailor your answers to showcase your skills and align with the job requirements.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Stencil Printer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.