Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stiffener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

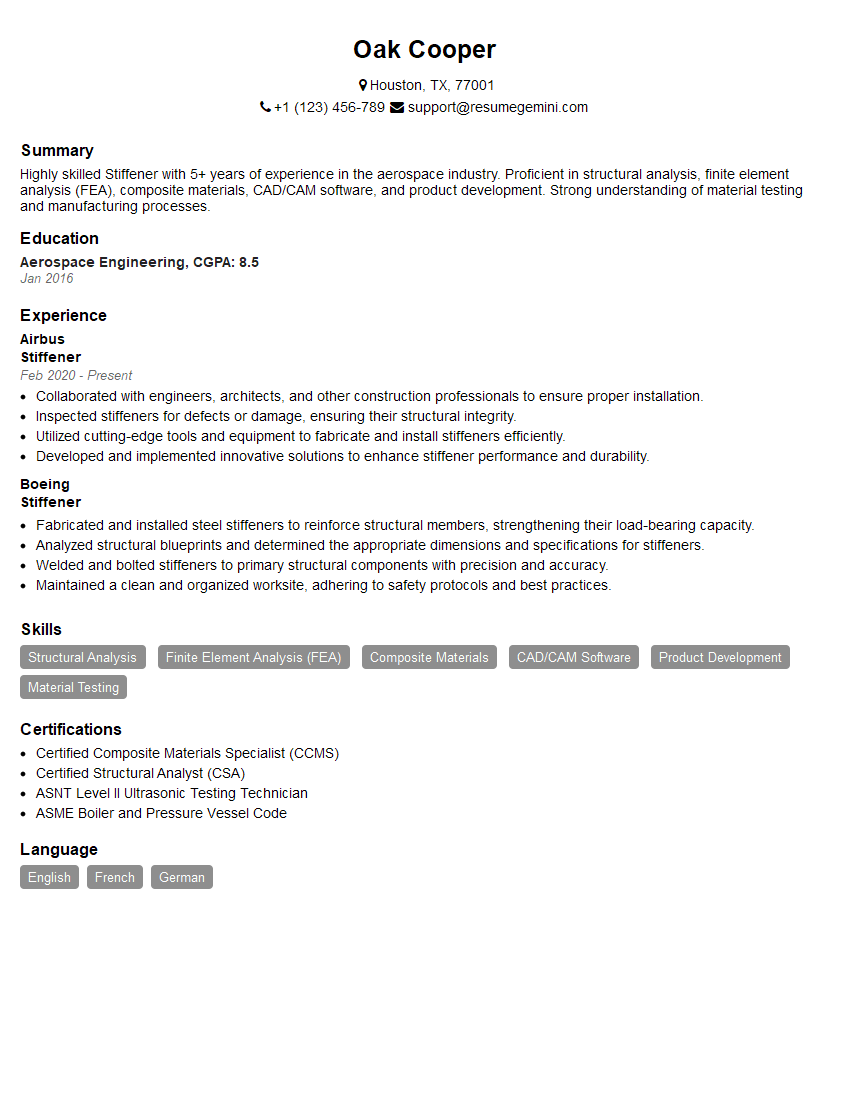

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stiffener

1. Can you explain the concept of primary and secondary stiffeners in ship structures?

Sample Answer: * Primary stiffeners are the main load-bearing members of a ship structure, providing longitudinal strength and resisting bending moments. * Secondary stiffeners are auxiliary members that support the primary stiffeners and distribute loads more evenly across the structure.

2. What are the different types of stiffener arrangements used in ship design?

Types of Stiffener Arrangements

- Longitudinal

- Transverse

- Diagonal

Factors Considered for Selection

- Structural requirements (e.g., load distribution, support spacing)

- Manufacturing considerations (e.g., accessibility, welding complexity)

- Architectural considerations (e.g., space allocation, aesthetics)

3. How do you determine the appropriate stiffness of a stiffener for a given application?

Sample Answer: * Consider the load conditions that the stiffener will experience. * Calculate the moment of inertia required for the stiffener to resist the bending moment. * Select a stiffener profile with a moment of inertia that meets or exceeds the calculated value.

4. What are the factors that affect the buckling behavior of stiffeners?

- Stiffener geometry (length, cross-sectional shape)

- Material properties (Young’s modulus, yield strength)

- Boundary conditions (fixed, pinned)

- Load distribution

5. How do you calculate the allowable compressive stress for a stiffener undergoing buckling?

Sample Answer: * Use the Euler buckling formula or appropriate design code (e.g., ABS, DNV). * Consider the stiffener’s geometry, material properties, and boundary conditions.

6. What are the common failure modes for stiffeners in ship structures?

- Buckling (compressive failure)

- Yielding (tensile failure)

- Corrosion

- Fatigue

7. How do you design a stiffener to resist corrosion?

- Use corrosion-resistant materials (e.g., stainless steel, aluminum)

- Apply protective coatings (e.g., paint, cathodic protection)

- Design for drainage and ventilation to minimize water retention

8. What finite element analysis (FEA) techniques are used in stiffener design?

- Static analysis (to determine stresses and displacements under various load conditions)

- Buckling analysis (to predict the onset of buckling)

- Fatigue analysis (to assess the lifespan of the stiffener under cyclic loading)

9. What software packages are commonly used for stiffener design and analysis?

- ANSYS

- NASTRAN

- ABAQUS

- FEMAP

10. What are the current industry best practices for stiffener design and optimization?

- Use of high-strength materials to reduce weight and improve efficiency

- Optimization techniques to minimize material usage while meeting structural requirements

- Advanced joining methods (e.g., laser welding, adhesive bonding)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stiffener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stiffener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stiffener is responsible for installing and maintaining various types of stiffeners in a variety of settings, such as residential, commercial, and industrial buildings. The key job responsibilities of a Stiffener include:

1. Installation of Stiffeners

Installs stiffeners in accordance with blueprints and specifications.

- Determines the location and orientation of stiffeners based on structural drawings.

- Selects and prepares the appropriate stiffeners for installation.

- Installs stiffeners using a variety of techniques, such as welding, bolting, or riveting.

2. Maintenance of Stiffeners

Inspects stiffeners for damage or wear.

- Repairs or replaces damaged or worn stiffeners.

- Tightens loose bolts or rivets.

3. Other Duties

Performs other duties as assigned, such as:

- Assisting in the fabrication of stiffeners.

- Providing technical support to other workers.

- Maintaining a clean and organized work area.

Interview Tips

To help candidates ace their interview for a Stiffener position, here are some tips and preparation hacks:

1. Research the Company and the Position

Before the interview, candidates should thoroughly research the company and the specific Stiffener position they are applying for. This will help them understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to learn about the latest trends and developments in the field.

- Connect with current or former employees on LinkedIn.

2. Practice Answering Common Interview Questions

Candidates should prepare for common interview questions related to their skills, experience, and qualifications. They should also be able to articulate how their skills and experience align with the requirements of the Stiffener position.

- Use the STAR method to answer questions about your experience.

- Be prepared to discuss your strengths and weaknesses.

- Have questions prepared to ask the interviewer.

3. Highlight Your Relevant Skills and Experience

Candidates should highlight their relevant skills and experience in their resume and during the interview. They should focus on skills that are essential for the Stiffener position, such as:

- Installation and maintenance of stiffeners

- Welding, bolting, or riveting experience

- Blueprint reading and interpretation

- Attention to detail and quality control

4. Dress Professionally and Arrive on Time

Candidates should dress professionally for the interview and arrive on time. This will demonstrate their respect for the interviewer and the company.

- Wear a suit or business casual attire.

- Be punctual and arrive at the interview location 10-15 minutes early.

- Bring a portfolio or other materials that showcase your skills and experience.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stiffener interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!