Are you gearing up for an interview for a Still Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Still Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

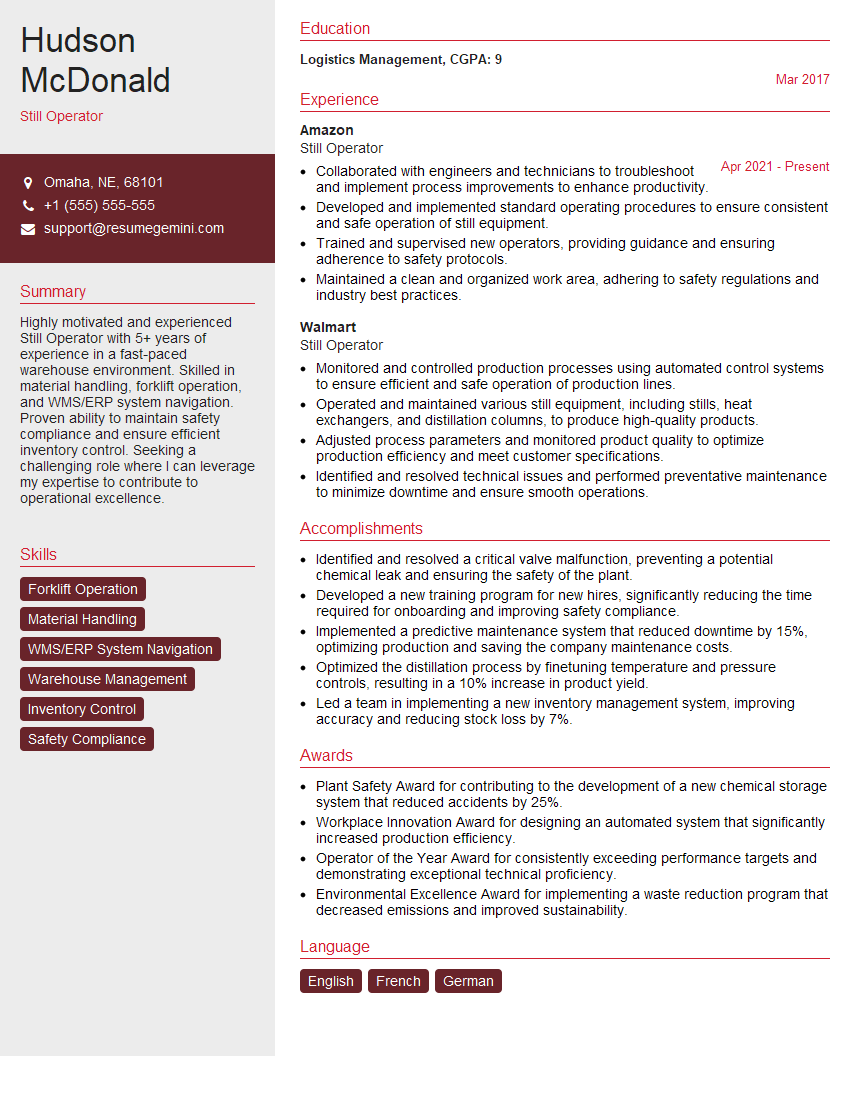

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Still Operator

1. What are the key responsibilities of a Still Operator?

- Operating and maintaining still equipment.

- Monitoring and controlling the distillation process.

- Ensuring the quality of the distilled products.

- Maintaining a clean and safe work environment.

- Following safety protocols and procedures.

2. What are the different types of stills used in the industry?

Batch stills

- Used for small-scale production.

- The distillation process is carried out in batches.

Continuous stills

- Used for large-scale production.

- The distillation process is continuous.

3. What are the factors that affect the efficiency of a distillation process?

- Type of still used.

- Temperature and pressure of the process.

- Composition of the feedstock.

- Efficiency of the condenser.

- Operator skill and experience.

4. How do you troubleshoot a distillation column that is not performing to specifications?

- Check the feedstock composition.

- Check the temperature and pressure of the process.

- Check the efficiency of the condenser.

- Check for leaks in the system.

- Calibrate the instrumentation.

5. What are the safety precautions that must be taken when operating a still?

- Wear appropriate personal protective equipment (PPE).

- Follow all written safety procedures.

- Be aware of the hazards of the chemicals being used.

- Do not operate a still if you are not trained and authorized.

- Never leave a still unattended while it is in operation.

6. What are the maintenance procedures that must be performed on a still?

- Regularly clean the still and all associated equipment.

- Inspect the still for any signs of damage or wear.

- Lubricate all moving parts.

- Calibrate the instrumentation.

- Follow the manufacturer’s recommended maintenance schedule.

7. What are the different types of distillation products that can be produced?

- Alcohols

- Essential oils

- Pharmaceuticals

- Solvents

- Water

8. What are the advantages and disadvantages of using a batch still?

Advantages

- Can be used for small-scale production.

- Can be used to produce a variety of products.

- Relatively simple to operate.

Disadvantages

- Can be less efficient than a continuous still.

- Can be more labor-intensive than a continuous still.

9. What are the advantages and disadvantages of using a continuous still?

Advantages

- Can be used for large-scale production.

- Can be more efficient than a batch still.

- Can be less labor-intensive than a batch still.

Disadvantages

- Can be more expensive to purchase and operate than a batch still.

- Can be more difficult to operate than a batch still.

10. What are the career advancement opportunities for a Still Operator?

- Supervisor

- Manager

- Process Engineer

- Quality Assurance Manager

- Technical Sales Representative

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Still Operators are responsible for the efficient and safe operation of various types of stills and other related equipment in a variety of industries, including chemical, pharmaceutical, and food manufacturing. Their primary duties involve overseeing the distillation process, ensuring that the desired products are produced within specified parameters. Let’s explore the key job responsibilities of a Still Operator in greater detail:

1. Monitoring and Controlling Distillation Processes

Still Operators are responsible for monitoring and controlling distillation processes to ensure that they are operating efficiently and safely. They adjust process variables, such as temperature, pressure, and flow rates, to maintain optimal operating conditions.

- Continuously monitor process parameters using instruments and control systems

- Make necessary adjustments to process variables to maintain product quality and efficiency

2. Maintaining and Troubleshooting Equipment

Still Operators are responsible for maintaining and troubleshooting equipment to ensure that it is operating properly. They perform routine maintenance tasks, such as cleaning, lubricating, and inspecting equipment, and they troubleshoot and repair any issues that may arise.

- Perform regular maintenance tasks, such as cleaning, lubricating, and inspecting equipment

- Troubleshoot and repair equipment malfunctions to minimize downtime

3. Ensuring Product Quality

Still Operators are responsible for ensuring the quality of the products produced by the distillation process. They collect and analyze samples, and they make adjustments to the process as needed to meet product specifications.

- Collect and analyze product samples to ensure they meet quality standards

- Make adjustments to the process to correct any deviations from product specifications

4. Following Safety Procedures

Still Operators must follow all safety procedures and regulations to ensure the safety of themselves and others. They are responsible for wearing appropriate personal protective equipment, and they must be aware of the potential hazards associated with the distillation process.

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and respirators

- Follow all safety procedures and regulations to minimize the risk of accidents

Interview Tips

Preparing for a Still Operator interview can help you showcase your skills and experience and increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and it will allow you to tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on the latest trends

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview. You can practice with a friend or family member, or you can use online resources to find practice questions.

- Prepare answers to questions about your experience, skills, and qualifications

- Practice answering questions about your knowledge of the distillation process and equipment

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Choose conservative colors and avoid wearing anything too revealing

- Make sure your clothes are clean and well-pressed

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Arrive for your interview on time, or even a few minutes early. This will give you time to relax and prepare before the interview begins.

- Plan your route and allow extra time for traffic and parking

- If you are running late, call or email the interviewer to let them know

5. Be Yourself

During the interview, it is important to be yourself. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let your personality shine through.

- Be confident in your abilities and experience

- Don’t be afraid to ask questions

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Still Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.