Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Stitch Bonding Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Stitch Bonding Machine Tender so you can tailor your answers to impress potential employers.

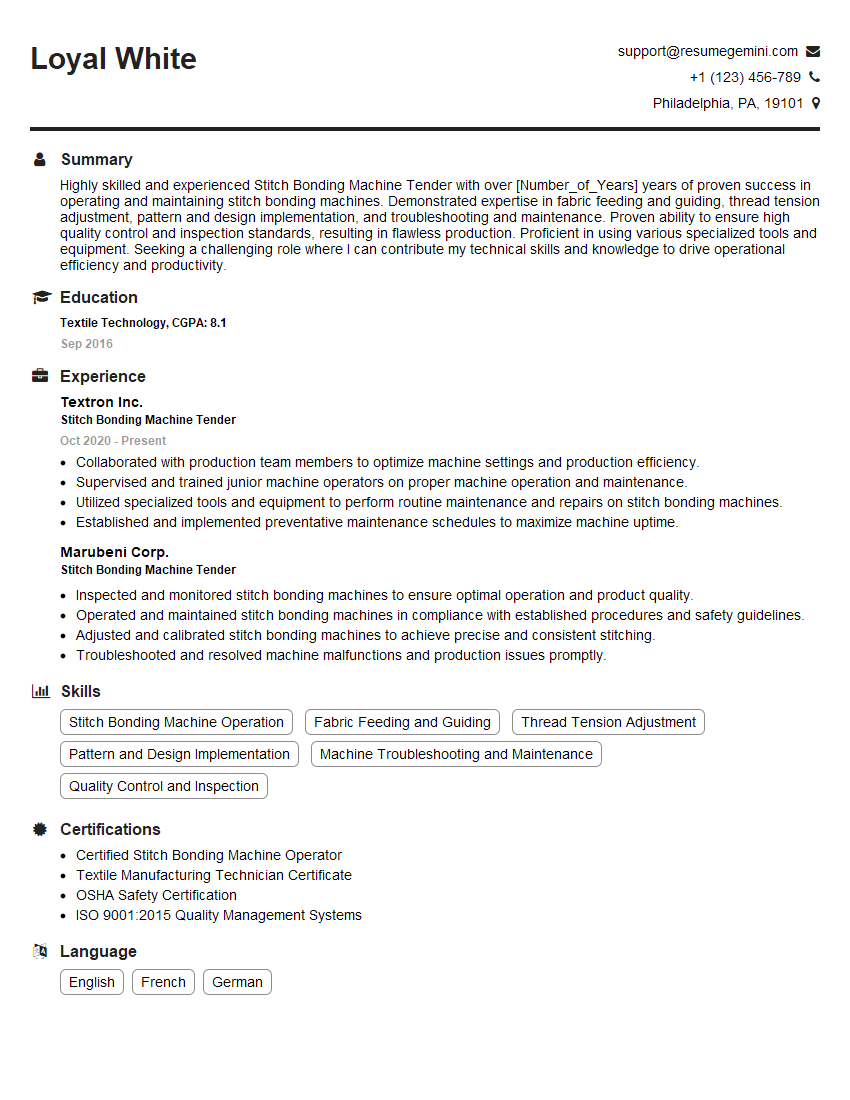

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stitch Bonding Machine Tender

1. Explain the process of threading the Stitch Bonding Machine?

- Set up the machine by installing the correct needles and thread.

- Follow the threading path diagram and insert the thread through the tension discs and guides.

- Pass the thread through the needle bar and hook the thread onto the needle.

- Adjust the thread tension to ensure proper stitch formation.

- Check the timing of the needle and hook to prevent thread breakage.

2. What are the different types of stitches used in Stitch Bonding Machine?

Knit stitch

- Formed by a series of interlocking loops

- Creates a flexible and stretchy fabric

Chain stitch

- Formed by a series of linked loops

- Strong and durable, often used for garments and industrial fabrics

3. How do you set the machine to produce the desired stitch density?

- Adjust the stitch length setting on the machine’s control panel.

- Increase the stitch length to reduce stitch density (fewer stitches per inch).

- Decrease the stitch length to increase stitch density (more stitches per inch).

- Calibrate the machine to ensure accurate stitch length and consistency.

4. What are the common maintenance tasks required for a Stitch Bonding Machine?

- Regular cleaning and lubrication of the machine

- Checking and replacing needles and thread guides as needed

- Monitoring thread tension and making adjustments to ensure proper stitch formation

- Inspecting belts and pulleys for wear and tear

- Following the manufacturer’s recommended maintenance schedule

5. How do you troubleshoot a Stitch Bonding Machine that is producing uneven stitches?

- Check the needle for damage or bending

- Verify that the thread is properly tensioned

- Adjust the stitch length setting to ensure it is appropriate for the fabric

- Inspect the hook timing and make adjustments if necessary

- Clean the machine thoroughly to remove any lint or debris

6. What is the difference between a single-needle and a multi-needle Stitch Bonding Machine?

Single-needle

- Uses one needle to create a narrow seam

- Suitable for small-scale production or specialized applications

Multi-needle

- Uses multiple needles to create a wider seam

- Increases productivity and efficiency

- Versatile for various types of fabrics and applications

7. How do you determine the correct thread tension for different fabrics?

- Consult the manufacturer’s recommendations for thread tension settings

- Experiment with different tension settings on a small piece of fabric

- Observe the stitch formation and adjust the tension until you achieve the desired result

- Consider the fabric’s weight, texture, and intended use when setting thread tension

8. What are the safety precautions that must be followed when operating a Stitch Bonding Machine?

- Always wear appropriate safety gear, including proper footwear, gloves, and eye protection

- Keep hands away from moving parts of the machine

- Do not reach into the machine while it is running

- Be aware of the machine’s operating temperature to avoid burns

- Follow all manufacturer’s instructions and safety guidelines

9. Explain the process of joining two pieces of fabric using a Stitch Bonding Machine?

- Overlap the two fabric edges by the desired seam allowance

- Align the fabric under the machine’s presser foot

- Start stitching along the seam line, guiding the fabric evenly

- Trim any excess fabric from the seam allowance once the stitching is complete

- Inspect the seam for proper stitch formation and strength

10. What are the challenges you have faced as a Stitch Bonding Machine Tender and how did you overcome them?

- Example Challenge: Maintaining consistent stitch quality on delicate fabrics

- Solution: Experimented with different stitch settings, adjusted thread tension, and used specialized needles designed for delicate materials

- Example Challenge: Troubleshooting machine malfunctions and breakdowns

- Solution: Followed manufacturer’s maintenance guidelines, consulted technical manuals, and sought assistance from experienced technicians when needed

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stitch Bonding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stitch Bonding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stitch Bonding Machine Tenders are responsible for operating and maintaining stitch bonding machines, which create fabrics by interlocking fibers together. They are also responsible for ensuring that the fabrics meet quality standards.

1. Loading Fabric Rolls

Stitch Bonding Machine Tenders load rolls of fabric onto the machine and thread the fabric through the machine’s guides.

- Inspect fabric rolls for defects before loading them onto the machine.

- Thread the fabric through the machine’s guides correctly to ensure that the fabric is properly stitched.

2. Operating the Machine

Stitch Bonding Machine Tenders operate the machine to stitch the fabric together. They adjust the machine’s settings to ensure that the fabric is stitched to the desired specifications.

- Monitor the machine’s operation to ensure that the fabric is being stitched correctly.

- Adjust the machine’s settings as needed to ensure that the fabric is stitched to the desired specifications.

3. Inspecting Fabric

Stitch Bonding Machine Tenders inspect the fabric after it has been stitched to ensure that it meets quality standards. They also check for defects in the fabric.

- Visually inspect the fabric for defects, such as holes, tears, or uneven stitching.

- Use a magnifying glass to inspect the fabric for defects that are not visible to the naked eye.

4. Maintaining the Machine

Stitch Bonding Machine Tenders perform routine maintenance on the machine to keep it in good working condition. They also clean the machine and lubricate its moving parts.

- Clean the machine regularly to remove dust and debris.

- Lubricate the machine’s moving parts to reduce wear and tear.

- Inspect the machine regularly for signs of wear and tear and make repairs as needed.

Interview Tips

To ace your interview for a Stitch Bonding Machine Tender position, there are several things you can do to prepare. First, you should research the company and the position itself. This will give you a good understanding of the company’s culture and the expectations for the role.

1. Prepare for Common Interview Questions

There are several common interview questions that you are likely to be asked in an interview for a Stitch Bonding Machine Tender position. These questions include:

- Tell me about your experience operating stitch bonding machines.

- What are the different types of fabrics that you have worked with?

- How do you ensure that the fabric meets quality standards?

- What is your experience with maintaining and repairing stitch bonding machines?

In answering these questions, be sure to highlight your skills and experience that are relevant to the position. For example, if you have experience operating a specific type of stitch bonding machine, be sure to mention this in your answer.

2. Practice Your Answers

Once you have prepared your answers to common interview questions, it is important to practice your answers so that you can deliver them confidently and clearly in the interview. You can practice your answers by speaking them aloud in front of a mirror or by recording yourself and then playing back the recording.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also make sure that your hair and makeup are neat and tidy.

4. Be Punctual

Punctuality is important in any interview, but it is especially important in an interview for a manufacturing position. Arriving late for your interview can make a bad impression on the interviewer and may even lead to you being disqualified for the position.

5. Be Enthusiastic

Employers are looking for candidates who are enthusiastic about the position and the company. Show the interviewer that you are excited about the opportunity to work for the company and that you are passionate about the role of a Stitch Bonding Machine Tender.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Stitch Bonding Machine Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.