Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stitcher Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

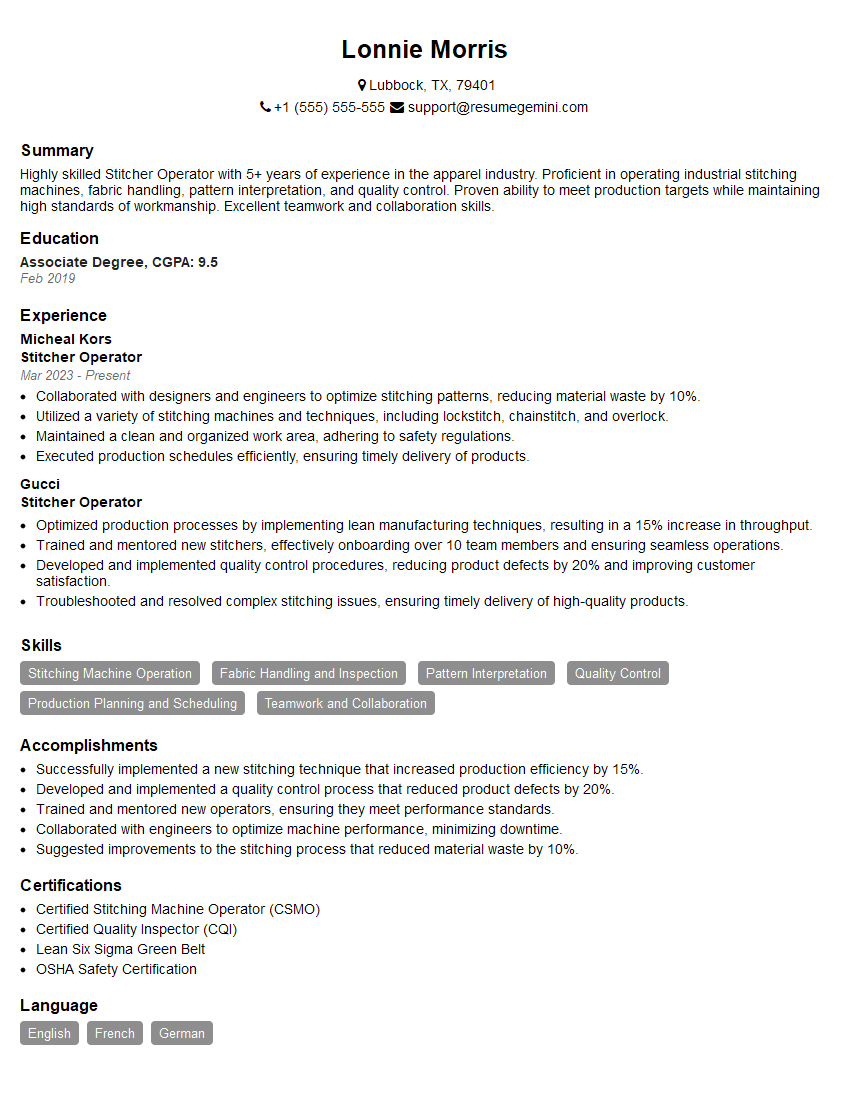

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stitcher Operator

1. Explain the stitching process?

The stitching process involves joining two or more pieces of fabric together using a sewing machine. It is a crucial step in garment manufacturing and ensures the durability and aesthetics of the final product. Here’s a general overview of the stitching process:

- Fabric preparation: Before stitching, the fabric pieces are prepared by cutting them to the desired shape and size, ensuring that the edges are clean and even.

- Thread selection: The type of thread used for stitching depends on the fabric weight, texture, and desired seam strength. The thread is chosen to match the color of the fabric or to create a contrasting effect.

- Machine setup: The sewing machine is set up according to the fabric type and the desired stitch type. This includes adjusting the tension, stitch length, and presser foot pressure.

- Stitching: The fabric pieces are placed under the presser foot, and the sewing machine is operated to stitch the pieces together. The operator guides the fabric through the machine, ensuring that the seam is straight and even.

- Seam finishing: After stitching, the seam is finished to prevent fraying and enhance its appearance. This can involve serging, zigzag stitching, or folding and pressing the seam allowances.

2. What are the different types of sewing machines used in stitching?

Industrial sewing machines

- Lockstitch machines: Used for general seaming and can produce a strong and durable stitch.

- Overlock machines: Used for finishing seams and preventing fraying by creating a wrapped stitch.

- Coverstitch machines: Used for creating a decorative and stretchy seam that is commonly seen on sportswear.

Domestic sewing machines

- Straight stitch machines: Basic machines suitable for simple sewing tasks like hems and repairs.

- Zigzag stitch machines: More versatile machines that can create a variety of stitches for decorative purposes or seam finishing.

- Sergers: Similar to industrial overlock machines, but designed for home use.

3. Describe the factors that affect the quality of a stitch?

- Thread quality: The strength and durability of the thread impact the stitch quality.

- Machine tension: Proper tension ensures that the thread is pulled through the fabric evenly, creating a balanced and secure stitch.

- Stitch length: The length of the stitches affects the strength and appearance of the seam.

- Needle size and type: The needle should be sharp and the correct size for the fabric and thread being used.

- Fabric type: Different fabrics require different stitch settings and techniques to achieve optimal results.

- Operator skill: The skill and experience of the operator play a crucial role in producing high-quality stitches.

4. How do you troubleshoot common stitching problems?

- Skipped stitches: Check thread tension, needle condition, and fabric thickness.

- Broken threads: Check thread quality, tension settings, and needle sharpness.

- Puckering or gathering: Adjust stitch length, tension, or use a different needle.

- Uneven seams: Ensure proper fabric alignment and adjust machine settings accordingly.

- Thread breakage: Check thread tension, needle condition, and bobbin winding.

5. What safety precautions should be taken while operating a sewing machine?

- Wear appropriate clothing: Avoid loose clothing or jewelry that could get caught in the machine.

- Keep hands away from the needle: Always use a seam guide or tweezers to handle fabric near the needle.

- Unplug the machine before making adjustments: This prevents accidental needle movement.

- Keep the work area clean and well-lit: Good visibility and a tidy workspace reduce the risk of accidents.

- Be aware of moving parts: Pay attention to the machine’s moving parts, such as the needle bar and bobbin winder.

6. How do you maintain a sewing machine to ensure optimal performance?

- Regular cleaning: Remove lint, dust, and fabric scraps from the machine after each use.

- Lubrication: Oil the machine according to the manufacturer’s instructions to reduce friction and wear.

- Needle replacement: Replace dull or damaged needles regularly to prevent skipped stitches and fabric damage.

- Bobbin winding: Ensure that the bobbin is wound evenly to prevent thread breakage.

- Tension adjustment: Check and adjust thread tension as needed to achieve balanced stitches.

7. What techniques do you use to achieve precise and consistent stitching?

- Use a seam guide: This tool helps maintain a straight and even seam allowance.

- Mark the fabric: Use chalk or fabric markers to guide your stitching and ensure accuracy.

- Stitch slowly and carefully: Taking your time allows for greater control and precision.

- Test stitch settings: Before stitching on the actual fabric, test the stitch length and tension on a scrap piece.

- Practice and experience: Regular practice and experience will improve your stitching skills and consistency.

8. How do you handle delicate fabrics when stitching?

- Use a fine needle: A smaller needle size reduces the risk of damaging the fabric.

- Adjust tension and stitch length: Use a lower tension and shorter stitch length to minimize puckering.

- Use tissue paper: Place tissue paper under delicate fabrics to provide support and prevent stretching.

- Hand-baste the fabric: Basting the fabric by hand before stitching helps stabilize it and prevent shifting.

- Use a light touch: Handle the fabric gently and avoid pulling or stretching it while stitching.

9. What techniques do you use to create decorative stitching?

- Zigzag stitch: Used for decorative edges, appliqués, and embellishments.

- Satin stitch: Creates a smooth and shiny surface, often used for embroidery and monogramming.

- Blanket stitch: A decorative stitch used for edging and embellishing blankets, throws, and other home décor items.

- Free-motion quilting: A technique that involves moving the fabric freely under the needle to create unique and artistic designs.

- Embroidery: Using a sewing machine to create intricate designs and patterns on fabric.

10. How do you stay updated on the latest stitching techniques and industry trends?

- Attend industry workshops and seminars: These events provide opportunities to learn new techniques and network with professionals.

- Read trade publications and online forums: Stay informed about the latest advancements and discussions within the industry.

- Follow industry experts on social media: Connect with skilled stitchers who share their knowledge and experiences online.

- Experiment with different techniques: Practice and experimentation help you develop your skills and explore new creative possibilities.

- Seek feedback from experienced stitchers: Ask for feedback and guidance from colleagues or mentors to improve your techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stitcher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stitcher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stitcher Operators perform various tasks in the manufacturing industry, including stitching and assembling materials to create finished products. Their duties are crucial in the production process and contribute significantly to the company’s output.

1. Operating Stitching Machinery

Stitcher Operators are proficient in operating stitching machinery to sew and assemble materials according to specifications. They ensure that the stitches are precise, even, and meet the required standards.

- Thread and operate sewing machines, adjust stitch length, tension, and other settings to ensure proper stitching.

- Inspect materials and adjust machine settings to achieve optimal stitching quality.

- Monitor stitching processes and make adjustments as needed to maintain consistent production.

2. Assembling and Joining Materials

Stitcher Operators assemble and join materials using stitching techniques. They follow patterns or instructions to create various products, such as clothing, accessories, or industrial components.

- Assemble components according to specifications, ensuring accuracy and precision.

- Sew and stitch materials together using appropriate stitching techniques.

- Inspect assembled products to ensure they meet quality standards.

3. Maintaining Work Area

Stitcher Operators maintain a clean and organized work area to ensure efficiency and safety. They keep the machinery and equipment in good working condition and follow safety protocols.

- Keep the work area clean and free from obstructions.

- Maintain and troubleshoot stitching machinery, perform minor repairs as needed.

- Follow safety procedures and wear appropriate protective gear.

4. Quality Control

Stitcher Operators play a vital role in quality control by inspecting the finished products and ensuring they meet the required standards. They identify and correct any defects or discrepancies.

- Inspect stitched products for defects, such as uneven stitches, loose threads, or improper assembly.

- Rectify any identified defects or deviations from specifications.

- Maintain records of inspections and any corrective actions taken.

Interview Tips

Preparing thoroughly for a Stitcher Operator interview can increase your chances of success. Here are a few tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company’s culture, values, and the specific requirements of the Stitcher Operator position. This will help you tailor your answers to the interviewer’s questions.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating stitching machinery, assembling materials, and maintaining a safe and efficient work environment. Provide specific examples from your previous work experience that demonstrate your skills.

3. Practice Answering Common Interview Questions

Prepare for questions such as “Why are you interested in this position?” and “What are your strengths and weaknesses as a Stitcher Operator?”. Practice answering these questions in a clear and concise manner.

4. Show Enthusiasm and Interest

Convey your passion for the manufacturing industry and your desire to contribute to the company’s success. Express your interest in learning new techniques and improving your skills as a Stitcher Operator.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer at the end. This shows that you are engaged in the conversation and interested in the company. Ask questions about the company’s growth plans, the training provided to employees, or the opportunities for career advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stitcher Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!