Feeling lost in a sea of interview questions? Landed that dream interview for Stock Preparation Operator (Stock Prep Operator) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Stock Preparation Operator (Stock Prep Operator) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

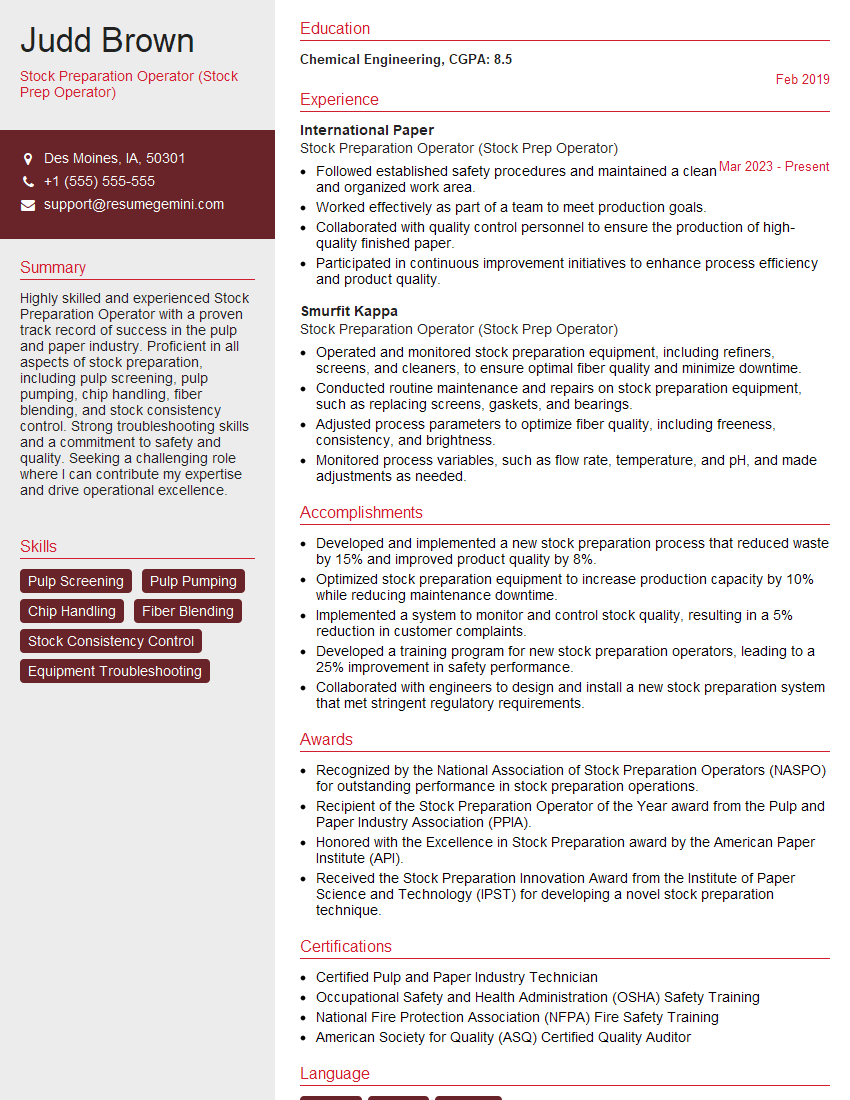

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stock Preparation Operator (Stock Prep Operator)

1. What are the main responsibilities of a Stock Preparation Operator?

- Monitoring and controlling the stock preparation process to ensure the production of pulp of desired quality and consistency.

- Operating and maintaining stock preparation equipment, including pulpers, refiners, and screens.

- Adjusting process parameters such as chemical dosages, temperature, and flow rates to optimize pulp quality.

- Monitoring equipment performance and identifying potential problems.

- Performing routine maintenance and repairs on stock preparation equipment.

- Following established safety and environmental regulations.

2. Describe the different types of pulping processes used in stock preparation.

Mechanical Pulping

- Groundwood Process: Uses mechanical force to grind wood into fibers.

- Thermomechanical Pulp (TMP): A combination of mechanical and thermal processes to produce pulp with higher strength.

Chemical Pulping

- Kraft Process (Sulfate Process): Uses a mixture of sodium hydroxide and sodium sulfide to dissolve lignin and produce strong pulp.

- Sulfite Process: Uses a mixture of sulfurous acid and bisulfite ions to dissolve lignin, producing pulp with high brightness and softness.

- Soda Process: Similar to Kraft process but uses sodium hydroxide instead of sodium sulfide, resulting in pulp with lower strength.

3. What are the key factors that affect pulp quality in stock preparation?

- Raw material characteristics (wood species, fiber length, etc.)

- Pulping process (type of process, chemical dosages, temperature)

- Equipment performance (pulper efficiency, screen mesh size)

- Process parameters (chemical addition rates, retention time)

- Environmental conditions (temperature, humidity)

4. How do you troubleshoot common problems in stock preparation?

- Poor pulp quality: Adjust process parameters, check equipment performance.

- Equipment failure: Identify the cause, perform repairs or maintenance.

- Process interruptions: Determine the source of the interruption, implement corrective actions.

- Safety hazards: Identify and mitigate potential risks, follow safety protocols.

5. What is the role of automation in modern stock preparation operations?

- Automated control systems: Monitor and adjust process parameters in real-time.

- Data acquisition systems: Collect and analyze data to optimize process efficiency.

- Predictive maintenance: Detect potential equipment problems before they occur.

- Reduced downtime and improved pulp quality.

6. Describe your experience in working with different types of stock preparation equipment.

- Pulpers: Batch and continuous pulpers, their operation and maintenance.

- Refiners: Disc refiners, conical refiners, their impact on pulp properties.

- Screens: Pressure screens, centrifugal screens, their role in pulp classification.

- Mixers and agitators: Types, applications, and their importance in stock preparation.

7. How do you ensure the proper operation and maintenance of stock preparation equipment?

- Regular inspections and preventive maintenance.

- Calibration and adjustment of equipment.

- Lubrication and replacement of worn parts.

- Monitoring equipment performance and addressing any issues promptly.

- Following manufacturer’s recommendations and industry best practices.

8. What are the safety precautions that need to be followed in a stock preparation plant?

- Wearing appropriate personal protective equipment.

- Following lockout/tagout procedures when working on equipment.

- Being aware of potential hazards, such as moving machinery and chemical spills.

- Adhering to established safety rules and regulations.

- Reporting any unsafe conditions or practices.

9. How do you stay updated with the latest advancements and best practices in stock preparation?

- Attending industry conferences and workshops.

- Reading technical publications and research papers.

- Participating in online forums and discussions.

- Networking with other professionals in the field.

- Seeking professional development opportunities, such as certification courses.

10. Describe your experience in working as part of a team in a stock preparation plant.

- Collaborating with colleagues to ensure smooth operation of the plant.

- Communicating effectively and sharing knowledge.

- Supporting team members with their tasks and responsibilities.

- Working towards common goals and objectives.

- Maintaining a positive and productive work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stock Preparation Operator (Stock Prep Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stock Preparation Operator (Stock Prep Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Stock Preparation Operator is responsible for preparing and controlling the stock for a paper mill. This includes overseeing the efficient operation of stock preparation equipment, maintaining a consistent quality, and ensuring the correct proportion of raw materials is used.

1. Equipment Operation

operates and monitors equipment used in stock preparation, such as pulpers, beaters, jordans, and refiners.

- Conducts routine maintenance and repairs on equipment.

- Performs quality checks on the stock to ensure it meets specifications.

2. Raw Material Handling

Controls the addition of raw materials to the stock, such as pulp, chemicals, and dyes.

- Ensures the correct proportions of raw materials are used.

- Monitors the stock consistency to maintain the desired quality.

3. Process Control

Monitors and controls the stock preparation process to ensure it operates smoothly.

- Adjusts process parameters as needed to maintain the desired stock quality.

- Troubleshoots and resolves any issues that arise.

4. Safety

Follows all safety protocols and procedures related to stock preparation.

- Wears appropriate personal protective equipment.

- Maintains a clean and organized work area.

Interview Tips

An interview is one of the most important aspects to crack the application of a job you desire. An interview is not only about answering the questions perfectly but also about understanding the basic expectations from the job you have applied for. To ace the interview for the post of Stock Preparation Operator, following are some of the tips and tricks.

1. Research the Company and the Position

Before going to an interview, it is very important to know about the company you have applied for and also about the job position you have applied for. This will help you in understanding the nature of work and responsibilities of the job more clearly.

- Visit the company’s website to learn about their history, mission, values, and products or services.

- Research the specific position you are interviewing for to understand the responsibilities and qualifications required.

2. Learn about Stock Preparation Process

As a Stock Preparation Operator, you must have basic knowledge of the Stock Preparation process. You should know about the different types of pulpers, beaters, jordans, and refiners used in the process.

- Read articles and watch videos about stock preparation to gain a better understanding of the process.

- If possible, try to visit a paper mill to see the stock preparation process in action.

3. Practice Answering Common Interview Questions

There are common interview questions that are asked in most of the interviews. You can prepare the answers for those questions beforehand, this will help you in facing them more confidently.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with stock preparation?

- How do you handle working in a team environment?

4. Dress Professionally and Arrive on Time

First impression creates a long-lasting impact, therefore, it is very important to dress professionally and arrive on time for the interview.

- Wear clean and pressed clothes that are appropriate for a business setting.

- Arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time.

5. Be Enthusiastic and Positive

Your enthusiasm and positive attitude can leave a great impact on the interviewer. Show the interviewer that you are interested in the position and that you are excited about the opportunity to work for the company.

- Smile and make eye contact with the interviewer.

- Be confident in your answers and speak clearly and concisely.

Next Step:

Now that you’re armed with the knowledge of Stock Preparation Operator (Stock Prep Operator) interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Stock Preparation Operator (Stock Prep Operator) positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini