Are you gearing up for an interview for a Stone Derrickman and Rigger position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Stone Derrickman and Rigger and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

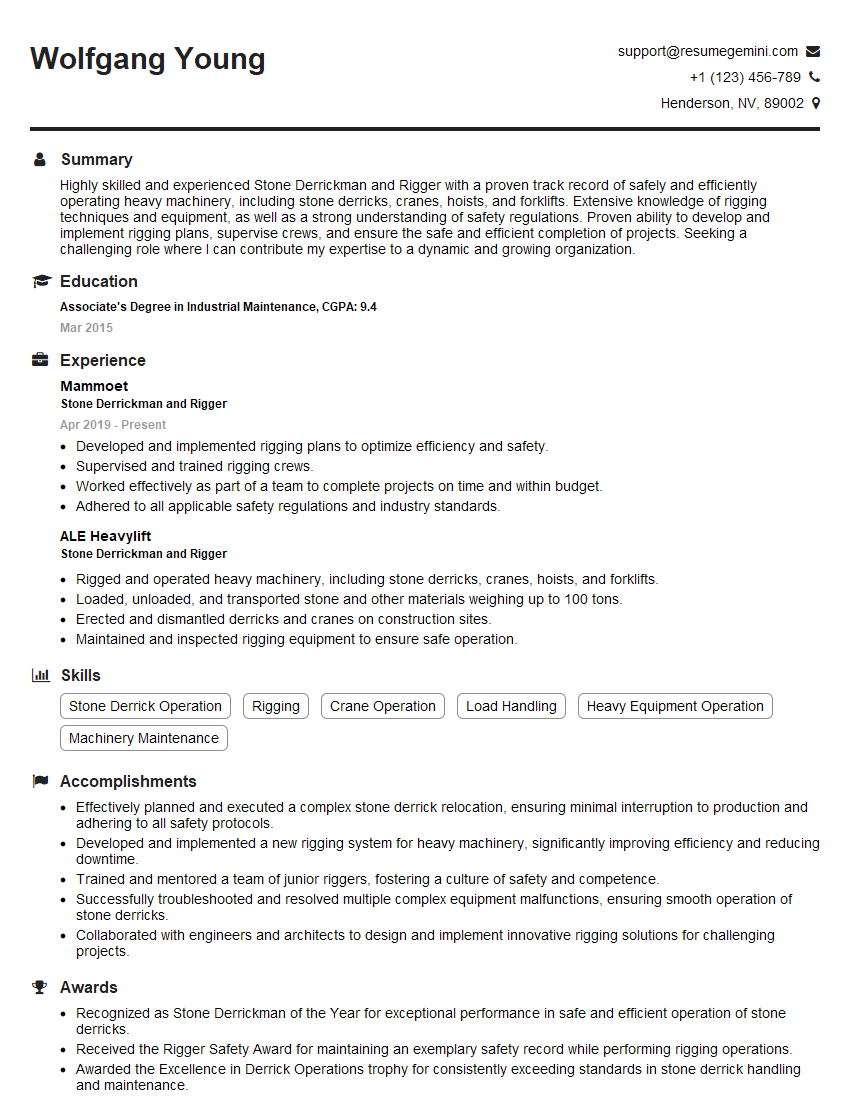

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stone Derrickman and Rigger

1. How would you inspect a wire rope for damage or deterioration?

To inspect a wire rope for damage or deterioration, I would follow these steps:

- Visual Inspection: I would visually inspect the rope for any signs of wear, corrosion, or damage, such as broken wires, fraying, or kinking.

- Hand Inspection: I would run my hands along the rope’s surface to feel for any irregularities or burrs that may indicate damage.

- Magnetic Particle Inspection: If necessary, I would use magnetic particle inspection to detect any surface or near-surface cracks.

- Ultrasonic Inspection: This non-destructive testing method can detect internal flaws, such as cracks or voids, which may not be visible during visual inspection.

2. What are the different types of slings used in rigging operations?

The different types of slings used in rigging operations include:

- Wire Rope Slings: Made of high-tensile steel wire strands and used for heavy lifting and load securing.

- Chain Slings: Constructed from alloy steel chains and suitable for lifting and securing heavy objects in harsh environments.

- Web Slings: Made of synthetic fibers and used for lifting and securing irregularly shaped or delicate objects.

- Synthetic Round Slings: Manufactured from high-strength synthetic fibers and used for lifting and securing cylindrical objects.

- Bridle Slings: Assembled from multiple slings connected to a central point, used for lifting and stabilizing large or oddly shaped objects.

3. How do you calculate the safe working load (SWL) of a lifting assembly?

To calculate the SWL of a lifting assembly, I would consider the following factors:

- Strength Rating of Components: I would determine the SWL of each component in the assembly, including the crane, rigging equipment, and slings.

- Load Factor: I would apply a load factor to account for dynamic forces and safety margin, typically ranging from 4:1 to 6:1.

- Configuration Factor: I would consider the angle of the slings and the load’s center of gravity to determine the configuration factor.

- Environmental Factors: I would adjust the SWL based on any potential environmental factors, such as temperature extremes or corrosive conditions.

4. What are the essential safety precautions to consider when working with cranes?

When working with cranes, I would adhere to the following safety precautions:

- Proper Planning: I would ensure that the lift is properly planned and supervised, with a qualified signaler present.

- Load Assessment: I would verify the weight and dimensions of the load and ensure it is within the crane’s capacity.

- Inspection: I would inspect the crane and rigging equipment before each use, checking for any damage or defects.

- Communication: I would maintain clear communication between the crane operator, signaler, and other personnel involved in the lift.

- Emergency Procedures: I would familiarize myself with the emergency procedures for the crane and know how to respond in case of an incident.

5. How do you assess the stability of a lifted load?

To assess the stability of a lifted load, I would consider the following factors:

- Load Distribution: I would ensure that the load is evenly distributed and not concentrated on a single point.

- Sling Angle: I would keep the sling angles as close to vertical as possible to minimize lateral forces.

- Rigging Configuration: I would choose a rigging configuration that provides stability, such as using a spreader bar or multiple slings.

- Environmental Conditions: I would assess the wind speed and direction, as well as the potential for ground movement or vibrations.

6. What are the common causes of rigging accidents, and how can they be prevented?

Common causes of rigging accidents include:

- Overloading: Lifting loads that exceed the SWL of the equipment.

- Improper Inspection: Failing to inspect equipment before use or ignoring visible damage.

- Poor Communication: Misunderstandings or lack of communication between personnel.

- Environmental Hazards: Strong winds, slippery surfaces, or unstable ground conditions.

- Human Error: Mistakes or negligence on the part of the rigging crew.

To prevent rigging accidents, I would emphasize proper planning, training, and adherence to safety protocols.

7. How do you handle rigging operations in confined spaces?

When working in confined spaces, I would take the following precautions:

- Ventilation: Ensure adequate ventilation to prevent the accumulation of hazardous fumes or oxygen depletion.

- Limited Access: Plan the rigging operation carefully, considering the restricted space and potential obstacles.

- Communication: Establish clear communication methods with personnel outside the confined space.

- Emergency Preparedness: Have an emergency plan in place and provide necessary equipment, such as communication devices and rescue gear.

8. What are the different types of anchors used in rigging?

The different types of anchors used in rigging include:

- Ground Anchors: Buried underground and used for securing ropes or cables in soil or rock.

- Concrete Anchors: Embedded in concrete structures and used for attaching rigging equipment.

- Structural Anchors: Connected to structural members, such as beams or columns, to provide a secure attachment point.

- Natural Anchors: Utilizing natural features, such as trees or boulders, for anchoring purposes.

9. How do you ensure the proper tensioning of slings during a lift?

To ensure proper tensioning of slings during a lift, I would:

- Tensioning Devices: Use tensioning devices, such as turnbuckles or hydraulic tensioners, to adjust the tension of the slings.

- Visual Inspection: Observe the slings under load and check for any signs of over-tensioning or slack.

- Load Monitoring: Utilize load cells or other monitoring devices to measure the tension in the slings.

- Experience and Judgment: Rely on my experience and judgment to assess the appropriate tension based on the load and rigging configuration.

10. What is the importance of regular equipment maintenance in rigging operations?

Regular equipment maintenance in rigging operations is crucial because it:

- Ensures Safety: Maintained equipment minimizes the risk of accidents and injuries.

- Extends Equipment Lifespan: Proper maintenance prolongs the lifespan of rigging equipment and reduces the need for costly repairs.

- Improves Efficiency: Well-maintained equipment operates smoothly, reducing downtime and improving productivity.

- Complies with Regulations: Many jurisdictions have regulations requiring regular inspection and maintenance of rigging equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stone Derrickman and Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stone Derrickman and Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stone Derrickman and Riggers are responsible for setting up, dismantling, and operating derricks and rigging equipment. They work in the construction industry to erect buildings, bridges, and other structures.

1. Rigging and Hoisting:

They are responsible for selecting the appropriate equipment and materials, assembling them, and inspecting them for safety. They also operate cranes and other heavy equipment to move and position materials and equipment.

- Set up and operate derricks, cranes, and other rigging equipment.

- Inspect and maintain rigging equipment, following safety regulations.

- Coordinate with other crew members to ensure safe and efficient operations.

2. Installation and Dismantling:

They install and dismantle derricks and other equipment, connect them to power sources, and test them for proper operation. They also perform maintenance and repairs on the equipment.

- Assemble and disassemble derricks, booms, and other rigging systems.

- Install and connect electrical and hydraulic lines.

- Lubricate and maintain equipment, performing minor repairs.

3. Safety and Compliance:

They follow safety regulations and guidelines, including wearing appropriate safety gear, using proper techniques, and maintaining equipment in good condition.

- Follow safety protocols and regulations.

- Use personal protective equipment, such as helmets, safety glasses, and gloves.

- Inspect equipment regularly to ensure it meets safety standards.

4. Communication and Teamwork:

They work effectively with other crew members and communicate clearly to ensure smooth operations.

- Work as part of a team, collaborating with other crew members.

- Communicate effectively using hand signals, verbal cues, and radios.

- Understand and follow instructions from supervisors.

Interview Tips

Preparing for an interview for a Stone Derrickman and Rigger position can help you present yourself confidently and showcase your qualifications. Here are some tips to help you ace the interview:

1. Research the Company and Position:

Before the interview, research the company and the specific role you are applying for. This will help you understand their industry, values, and expectations.

- Visit the company’s website to learn about their history, services, and culture.

- Read industry publications and news articles to stay informed about the latest trends and developments.

2. Practice Your Answers:

Take time to practice answering common interview questions, such as those related to your experience, skills, and motivations. Prepare concise and well-structured responses that highlight your qualifications.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences and accomplishments.

- Quantify your results whenever possible to demonstrate the impact of your work.

3. Highlight Your Safety Consciousness:

Safety is paramount in this field. Emphasize your commitment to following safety protocols, maintaining a clean work environment, and prioritizing the well-being of yourself and your colleagues.

- Provide examples of your safety practices, such as regular equipment inspections and adherence to safety guidelines.

- Mention any safety certifications or training you have obtained.

4. Demonstrate Your Technical Skills:

Discuss your proficiency in operating derricks, cranes, and other rigging equipment. Explain your understanding of mechanical principles and your ability to troubleshoot and resolve technical issues.

- Describe your experience with specific types of equipment and rigging techniques.

- Mention any specialized knowledge or certifications you possess.

5. Showcase Your Teamwork and Communication Abilities:

Working effectively in a team is essential. Highlight your ability to communicate clearly, collaborate with others, and contribute to a positive work environment.

- Provide examples of successful teamwork projects and your role in them.

- Emphasize your proficiency in using hand signals and other communication methods used in rigging operations.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Stone Derrickman and Rigger, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Stone Derrickman and Rigger positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.