Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stone Sandblaster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

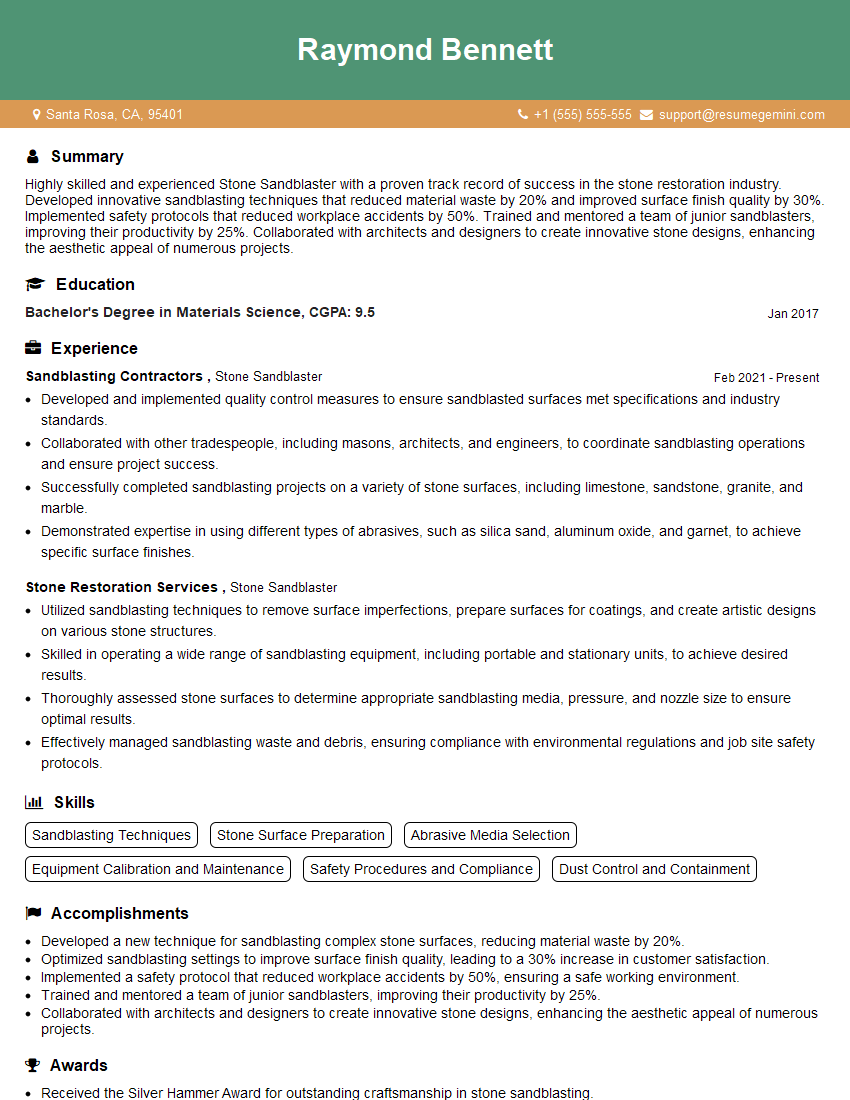

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stone Sandblaster

1. What is sandblasting and how does it differ from other surface preparation methods?

Sandblasting is a surface preparation method that uses a stream of abrasive material to clean and prepare a surface. It is different from other methods such as chemical cleaning, mechanical cleaning, and laser cleaning in that it is a more aggressive process that can remove more material and create a rougher surface. Sandblasting is often used to prepare surfaces for painting, coating, or bonding.

2. What are the different types of abrasive materials used in sandblasting?

The most common types of abrasive materials used in sandblasting are:

- Silica sand

- Garnet

- Steel shot

- Glass beads

- Walnut shells

The type of abrasive material used will depend on the surface being blasted and the desired finish.

3. What are the different grades of sandblasting abrasives?

Sandblasting abrasives are graded according to their size and shape. The most common grades are:

- Coarse

- Medium

- Fine

- Extra fine

The grade of abrasive used will depend on the surface being blasted and the desired finish.

4. What are the different types of sandblasting equipment?

There are two main types of sandblasting equipment: pressure-fed and suction-fed. Pressure-fed sandblasters use a compressor to pressurize the abrasive material and propel it through the nozzle. Suction-fed sandblasters use a vacuum to create a negative pressure that draws the abrasive material through the nozzle. Pressure-fed sandblasters are more powerful and can be used for a wider variety of applications, but suction-fed sandblasters are less expensive and easier to operate.

5. What are the safety precautions that must be taken when sandblasting?

Sandblasting can be a hazardous operation, so it is important to take proper safety precautions. These precautions include:

- Wearing appropriate protective clothing, including a respirator, gloves, and eye protection

- Working in a well-ventilated area

- Using proper grounding and bonding techniques

- Following all manufacturer’s instructions

6. What are the different applications for sandblasting?

Sandblasting is used in a wide variety of applications, including:

- Surface preparation for painting, coating, or bonding

- Cleaning and restoring surfaces

- Removing graffiti and other unwanted coatings

- Creating a decorative finish

7. What are the advantages of sandblasting?

Sandblasting offers a number of advantages over other surface preparation methods, including:

- It is a very effective way to remove dirt, rust, and other contaminants from a surface

- It can create a rough surface that is ideal for painting, coating, or bonding

- It is a relatively inexpensive process

- It is a portable process that can be used in a variety of locations

8. What are the disadvantages of sandblasting?

Sandblasting also has some disadvantages, including:

- It can be a hazardous operation if not done properly

- It can create a lot of dust and noise

- It can damage delicate surfaces if not done properly

- It can be time-consuming

9. How do you choose the right sandblasting abrasive for a particular application?

The type of sandblasting abrasive to use will depend on the surface being blasted and the desired finish. Some factors to consider include:

- The hardness of the surface

- The thickness of the coating being removed

- The desired surface finish

- The cost of the abrasive

10. How do you maintain a sandblasting machine?

To maintain a sandblasting machine, it is important to:

- Clean the machine regularly

- Inspect the machine for wear and tear

- Lubricate the machine regularly

- Follow all manufacturer’s instructions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stone Sandblaster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stone Sandblaster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stone Sandblaster, also known as a Stone Carver, is an artisan who specializes in sculpting and creating intricate designs on stone surfaces using pressurized sand. They play a crucial role in the construction and restoration of buildings, monuments, and other structures made of stone.

1. Design and Execution

Stone Sandblasters are responsible for translating design concepts into physical artworks. They collaborate with architects, designers, and clients to develop detailed plans and specifications for the desired stonework.

- Interpreting design drawings and translating them into sandblasting instructions.

- Selecting appropriate sandblasting techniques and materials based on the stone type and desired effect.

- Creating intricate designs and patterns on stone surfaces using specialized sandblasting equipment.

2. Stone Preparation and Maintenance

Stone Sandblasters ensure the proper preparation and maintenance of stone surfaces to achieve optimal results.

- Preparing stone surfaces by cleaning, leveling, and repairing any imperfections.

- Applying protective coatings or treatments to enhance the durability and appearance of stonework.

- Inspecting and maintaining stone surfaces to identify and address any damage or deterioration.

3. Technical Expertise and Safety

Stone Sandblasters must possess a deep understanding of the properties of different types of stone and the techniques used to work with them.

- Operating and maintaining sandblasting equipment safely and efficiently.

- Understanding the principles of stone carving and engraving.

- Staying up-to-date with industry best practices and advancements in sandblasting technology.

4. Collaboration and Communication

Stone Sandblasters work closely with other professionals involved in construction and restoration projects.

- Collaborating with architects, designers, and contractors to ensure the seamless integration of stonework into the overall project.

- Communicating effectively with clients to understand their needs and expectations.

- Documenting their work processes and providing technical reports as required.

Interview Preparation Tips for Stone Sandblasters

Preparing thoroughly for an interview as a Stone Sandblaster can significantly improve your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company you are applying to and the specific position you are seeking. This will give you a better understanding of their values, work culture, and the requirements of the role.

- Visit the company’s website, social media pages, and industry publications.

- Read about the company’s history, mission, and key projects.

- Identify the specific skills and experience the company is looking for in the job description.

2. Highlight Your Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience that are most relevant to the job requirements. Use specific examples to demonstrate your abilities in:

- Sandblasting techniques and equipment operation.

- Stone preparation and maintenance.

- Design and execution of stonework.

- Collaboration and communication.

3. Prepare for Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about your experience in stone sandblasting.

- Describe a project where you successfully used sandblasting to create a specific design or effect.

- What are the most challenging aspects of stone sandblasting?

- How do you stay up-to-date with the latest advancements in sandblasting technology?

4. Practice Your Presentation

Practice delivering your answers to the common interview questions. This will help you feel more confident and articulate during the actual interview. Consider using the STAR method to structure your answers:

- Situation: Describe the situation or task that you were faced with.

- Task: Explain the specific task that you needed to complete.

- Action: Describe the actions that you took to complete the task.

- Result: State the positive results or outcomes of your actions.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for the interview. Arrive on time, be polite to everyone you meet, and maintain a positive and enthusiastic attitude throughout the interview process.

- Wear clean and pressed business attire.

- Be on time for your interview and allow ample time for travel.

- Greet the interviewer with a firm handshake and make eye contact.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Stone Sandblaster, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Stone Sandblaster positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.