Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stonework Tracer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

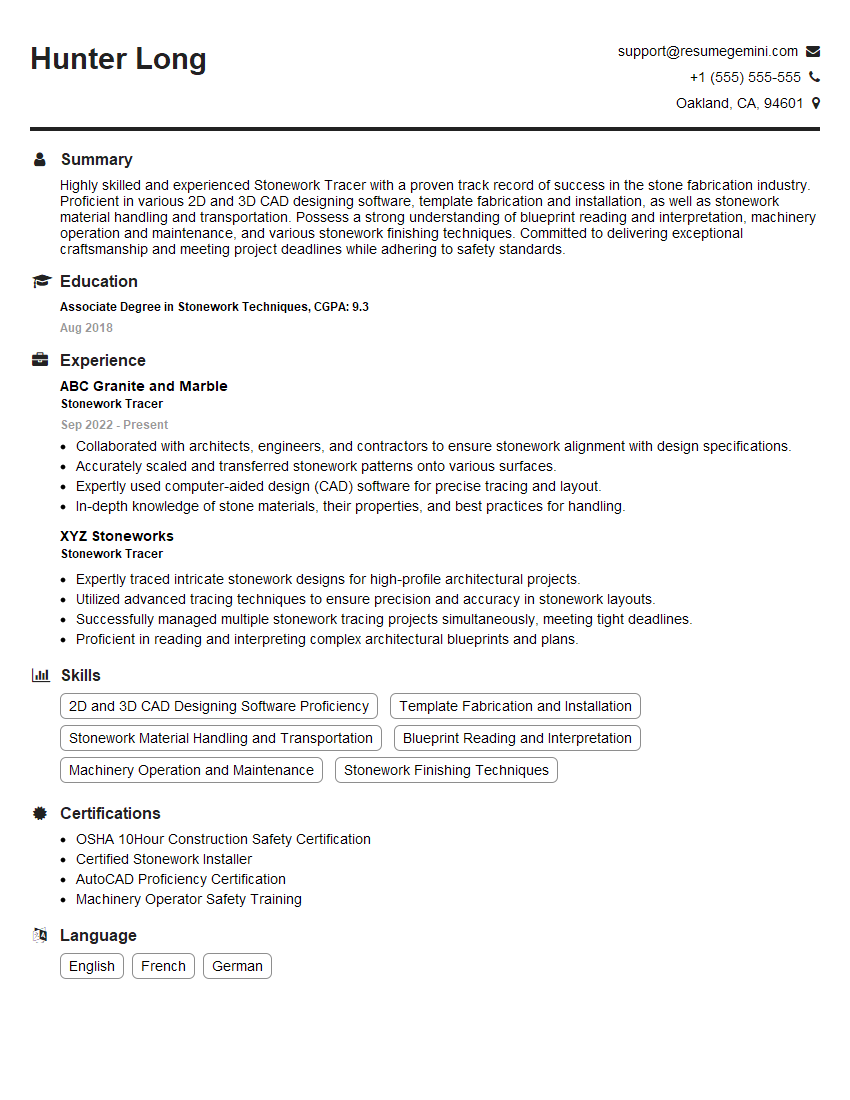

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stonework Tracer

1. How do you determine the correct stone type for a project?

To determine the correct stone type for a project, I consider the following factors:

- Intended use: The type of stone suitable for a project depends on its intended use, such as flooring, countertops, or exterior cladding.

- Environmental conditions: The stone’s resistance to weathering, moisture, and temperature fluctuations must be considered for the project’s location.

- Aesthetic preferences: The color, texture, and veining of the stone should align with the design aesthetic of the project.

- Budget and availability: The cost and availability of different stone types must be taken into account to ensure the project remains feasible.

2. Describe the different methods of stone extraction and their impact on the stone’s properties.

The primary methods of stone extraction are quarrying and mining:

Quarrying

- Open-pit quarrying: Involves removing the soil and bedrock to expose the stone deposit. This method is suitable for large-scale extraction and can produce blocks of various sizes.

- Underground quarrying: Utilizes tunnels and shafts to access the stone deposit. This method is used for extracting specific types of stone or when the deposit is located deep underground.

Mining

- Blasting: Explosives are used to break down the stone deposit into smaller pieces. This method is efficient but can damage the stone’s integrity.

- Diamond saws: Large saws with diamond-tipped blades are used to cut the stone into blocks. This method is less damaging to the stone but slower and more expensive.

The extraction method can affect the stone’s properties, such as durability, porosity, and color.

3. How do you ensure the quality of stone during the tracing process?

To ensure stone quality during tracing, I follow these steps:

- Visual inspection: I carefully examine the stone for any visible defects, such as cracks, fissures, or discolorations.

- Sound testing: I tap the stone with a hammer or mallet to listen for any hollow sounds that may indicate internal flaws.

- Resistivity testing: I use a resistivity meter to measure the stone’s resistance to electrical current, which can indicate its density and structural soundness.

- Core sampling and testing: I collect core samples from the stone and subject them to laboratory testing to determine their strength, durability, and other properties.

4. Can you describe the principles of stone cutting and the different techniques used?

Stone cutting involves using specialized tools and techniques to shape and size stone blocks. The primary principles of stone cutting are:

- Scoring: Using a chisel or saw to create a shallow groove along the desired cutting line.

- Splitting: Using wedges or hammers to separate the stone along the scored line, taking advantage of the stone’s natural cleavage planes.

- Sawing: Using saws with diamond-tipped blades to cut the stone into desired shapes and sizes.

Different techniques are used depending on the type of stone and the desired outcome:

- Hand cutting: Using chisels, hammers, and other hand tools for small-scale, detailed work.

- Machine cutting: Using power tools such as diamond-bladed saws for large-scale, precise cutting.

- Waterjet cutting: Using a high-pressure water jet with abrasive particles to cut complex shapes.

5. How do you handle and transport heavy stone blocks safely?

Handling and transporting heavy stone blocks require proper equipment and techniques to ensure safety:

- Equipment: Using cranes, forklifts, or other heavy machinery to lift and move the blocks.

- Slings and straps: Using specially designed slings and straps to securely lift and transport the blocks.

- Protective padding: Placing padding or cushioning materials around the blocks to prevent damage during transportation.

- Proper storage: Storing the blocks on stable surfaces and ensuring they are securely stacked to prevent tipping.

6. Can you explain the process of stone polishing and the different methods used?

Stone polishing involves using abrasive materials and equipment to smooth and enhance the surface of the stone:

- Mechanical polishing: Using polishing machines with diamond-tipped abrasives to remove imperfections and create a smooth surface.

- Hand polishing: Using hand tools and abrasive pads to polish smaller areas or intricate details.

- Chemical polishing: Using acid or alkaline solutions to dissolve certain minerals in the stone, resulting in a smooth finish.

The choice of polishing method depends on the type of stone, desired finish, and scale of the project.

7. What are the common challenges faced during stoneworking and how do you overcome them?

Common challenges in stoneworking include:

- Natural flaws: Dealing with natural cracks, fissures, or inclusions in the stone.

- Variations in stone properties: Accounting for differences in hardness, porosity, and color between different types of stone.

- Handling large and heavy blocks: Safely moving and positioning large stone blocks during cutting and installation.

- Environmental factors: Protecting the stone from moisture, temperature changes, and other environmental hazards.

To overcome these challenges, I use appropriate tools and techniques, consult with experts, and conduct thorough planning and preparation.

8. Describe the different types of stone finishes and their applications.

Common stone finishes include:

- Polished: A smooth, glossy finish achieved through mechanical or chemical polishing.

- Honed: A matte finish with a smooth but less reflective surface.

- Brushed: A textured finish created by brushing the stone with abrasive pads.

- Flamed: A rough finish achieved by exposing the stone to a high-temperature flame.

- Natural cleft: A split finish that retains the natural surface of the stone.

The choice of finish depends on the desired aesthetic, functionality, and intended use of the stone.

9. How do you stay updated on the latest advancements and best practices in stoneworking?

To stay updated, I:

- Attend industry conferences and workshops: Participate in events to learn about new technologies and best practices.

- Read industry publications and articles: Keep up with the latest research and developments in stoneworking.

- Network with other stoneworkers and professionals: Exchange knowledge and experiences with peers.

- Explore online resources and forums: Access information and connect with the global stoneworking community.

10. Describe a complex or challenging stoneworking project you have worked on and how you successfully completed it.

One memorable project involved the restoration of a historic stone facade. The challenge lay in matching the existing stone with newly sourced material and ensuring the new stone blended seamlessly. I meticulously examined the original stone, conducted thorough testing, and carefully selected replacement stone with similar properties. I collaborated with other craftsmen to develop a custom installation method that respected the building’s historical integrity and ensured the new stone would withstand the test of time.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stonework Tracer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stonework Tracer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stonework Tracers are responsible for preparing detailed drawings and templates from sketches, plans, and models. They may also be involved in the fabrication and installation of stonework elements.

1. Preparing Drawings and Templates

Stonework Tracers use a variety of software and tools to create detailed drawings and templates. They must be able to work accurately and precisely, as their work will be used to guide the fabrication and installation of stonework elements.

- Create detailed drawings and templates from sketches, plans, and models.

- Use a variety of software and tools to create drawings and templates.

- Work accurately and precisely to ensure that drawings and templates are accurate.

2. Fabricating and Installing Stonework Elements

Stonework Tracers may also be involved in the fabrication and installation of stonework elements. This may include cutting, shaping, and setting stonework. They must be able to work safely and efficiently to ensure that the stonework is installed correctly.

- Cut, shape, and set stonework elements.

- Work safely and efficiently to ensure that stonework is installed correctly.

- Follow blueprints and specifications to ensure that stonework is installed according to plan.

3. Inspecting Stonework

Stonework Tracers may also be responsible for inspecting stonework to ensure that it meets specifications. They may also be involved in troubleshooting and repairing stonework problems.

- Inspect stonework to ensure that it meets specifications.

- Troubleshoot and repair stonework problems.

- Maintain accurate records of stonework inspections and repairs.

Interview Tips

Preparing for an interview for a Stonework Tracer position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read the job description carefully to understand the specific requirements of the position.

- Look for news articles or other information about the company to get a sense of their culture and values.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Prepare a brief overview of your skills and experience that highlights your qualifications for the position.

- Research the company and the position to learn about their specific needs and how your skills and experience can meet those needs.

- Practice answering common interview questions out loud so that you can become more comfortable and confident in your delivery.

3. Be Prepared to Discuss Your Experience and Skills

The interviewer will want to know about your experience and skills as a Stonework Tracer. Be prepared to discuss your experience in detail, including your knowledge of software and tools, your fabrication and installation skills, and your inspection experience.

- Highlight your experience in preparing detailed drawings and templates from sketches, plans, and models.

- Describe your experience in fabricating and installing stonework elements.

- Discuss your experience in inspecting stonework to ensure that it meets specifications.

4. Be Professional and Enthusiastic

First impressions matter, so it is important to be professional and enthusiastic during your interview. Dress appropriately, arrive on time, and be polite and respectful to everyone you meet.

- Dress in business attire to show that you are taking the interview seriously.

- Arrive on time for your interview to show that you are respectful of the interviewer’s time.

- Be polite and respectful to everyone you meet, including the receptionist, the interviewer, and other employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stonework Tracer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!