Feeling lost in a sea of interview questions? Landed that dream interview for Stopboard Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Stopboard Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

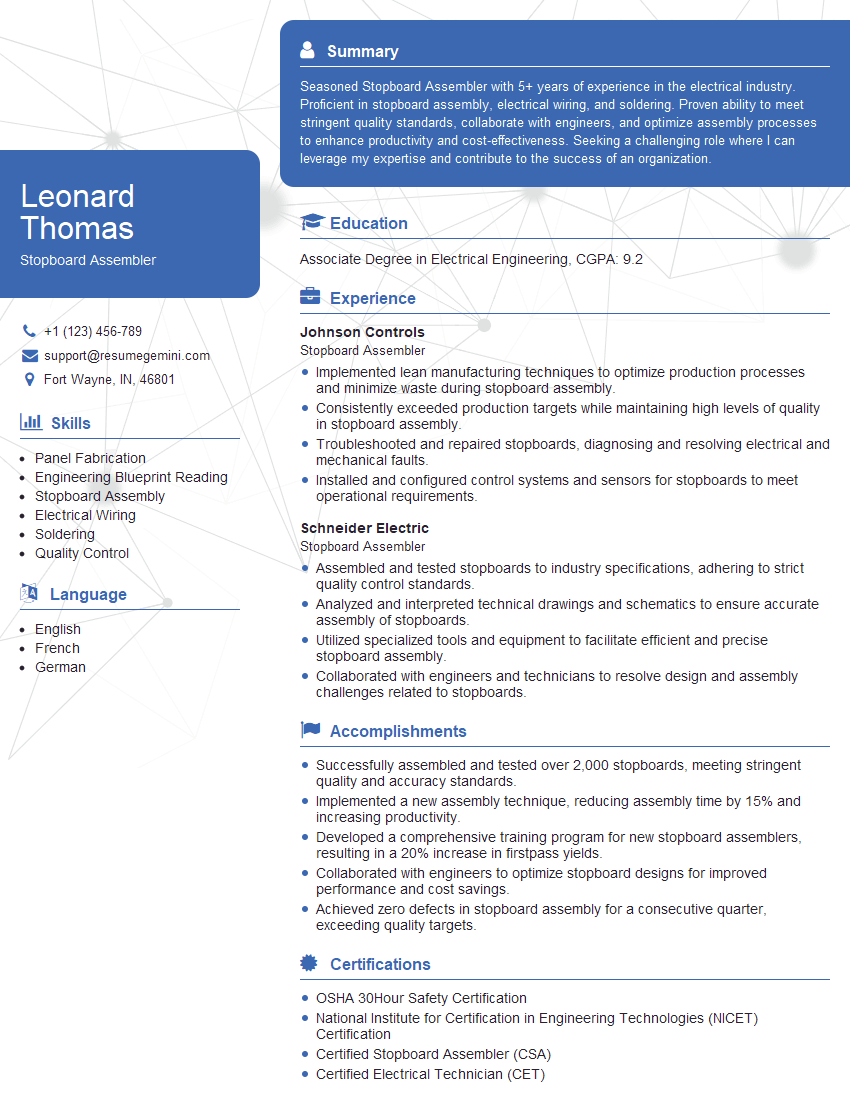

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stopboard Assembler

1. What are the key responsibilities of a Stopboard Assembler?

- Assembling and installing stopboards in switchboards and panel boards

- Reading and interpreting blueprints and wiring diagrams

- Using hand tools and power tools to cut, bend, and install stopboards

- Testing and inspecting stopboards to ensure they meet specifications

- Maintaining a clean and organized work area

2. What are the different types of stopboards?

- Main stopboards: These are the main circuit breakers that protect the entire electrical system.

- Branch stopboards: These are the circuit breakers that protect individual circuits.

- Feeder stopboards: These are the circuit breakers that protect the electrical feeders that supply power to the building.

- Service entrance stopboards: These are the circuit breakers that protect the electrical service entrance to the building.

3. What are the safety precautions that must be taken when working with stopboards?

- Always wear proper personal protective equipment (PPE), including safety glasses, gloves, and a hard hat.

- Never work on live circuits.

- Always use insulated tools.

- Be aware of the location of all electrical hazards.

- Follow all lockout/tagout procedures.

4. What are the troubleshooting techniques that can be used to identify and resolve problems with stopboards?

- Visual inspection: Look for any loose connections, damaged wires, or burnt components.

- Multimeter testing: Use a multimeter to test the voltage, current, and resistance of the stopboard.

- Circuit tracing: Use a circuit tracer to identify the path of the electrical current through the stopboard.

- Load testing: Apply a load to the stopboard to see if it trips.

5. What are the maintenance procedures that can be performed on stopboards?

- Regular cleaning: Use a soft brush or cloth to remove any dust or debris from the stopboard.

- Tightening connections: Check all connections to ensure that they are tight.

- Lubrication: Lubricate all moving parts, such as breakers and switches.

- Testing: Test the stopboard regularly to ensure that it is functioning properly.

6. What are the different types of materials that can be used to make stopboards?

- Copper: Copper is a good conductor of electricity and is often used for stopboards.

- Aluminum: Aluminum is a lighter and less expensive conductor than copper.

- Steel: Steel is a strong and durable material that can be used for stopboards.

- Thermoplastic: Thermoplastic is a non-conductive material that can be used for stopboards.

7. What are the different sizes and configurations of stopboards?

- Stopboards come in a variety of sizes and configurations to meet the needs of different applications.

- The most common size is a 12-inch by 24-inch stopboard.

- Stopboards can be configured with either single or double rows of circuit breakers.

- They can also be configured with different amperage ratings and trip settings.

8. What are the different codes and standards that apply to stopboards?

- National Electrical Code (NEC): The NEC is the national standard for electrical safety in the United States.

- Underwriters Laboratories (UL): UL is a safety certification organization that tests and certifies electrical products.

- Institute of Electrical and Electronics Engineers (IEEE): The IEEE is a professional organization that develops standards for electrical products.

9. What are the different manufacturers of stopboards?

- There are many different manufacturers of stopboards, including:

- Schneider Electric

- Eaton

- Siemens

- GE

10. What are the different career opportunities for Stopboard Assemblers?

- Stopboard Assemblers can advance their careers by becoming Electrical Maintenance Technicians or Electrical Engineers.

- They can also start their own businesses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stopboard Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stopboard Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stopboard Assembler is responsible for assembling, installing, and repairing various types of stopboards used in water distribution, flood control, and irrigation systems. Their duties encompass the fabrication and maintenance of stopboards, ensuring they meet specified design requirements and standards.

1. Stopboard Fabrication

Fabricate and assemble stopboards according to blueprints and specifications

- Cut, shape, and weld metal components using specialized tools and equipment

- Inspect materials and components for defects or damage

2. Stopboard Installation

Install and erect stopboards in designated locations

- Determine proper placement and alignment of stopboards

- Secure stopboards using bolts, nuts, and other fasteners

3. Stopboard Maintenance and Repair

Inspect, maintain, and repair stopboards to ensure proper functioning

- Identify and repair leaks, cracks, or damage to stopboards

- Lubricate moving parts and components

4. Equipment Operation

Operate and maintain various tools and equipment used in stopboard assembly and installation

- Use welding equipment, cutting tools, and measuring devices

- Maintain and calibrate tools and equipment

Interview Tips

Preparing thoroughly for an interview is essential for success. Here are some tips to help you ace your interview for a Stopboard Assembler position:

1. Research the Company and Role

Demonstrate your interest and knowledge by researching the company’s history, values, and current projects. Understanding the specific requirements of the Stopboard Assembler role will help you tailor your answers to the interviewer’s questions.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your responses. Anticipate questions about your skills, experience, and motivation for applying to the position. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Example Outline:

- Situation: Describe a time when you had to fabricate a stopboard from scratch.

- Task: Explain the steps involved in cutting, shaping, and welding the stopboard components.

- Action: Outline the specific techniques and tools you used to ensure precision and meet specifications.

- Result: Highlight the successful installation and performance of the stopboard, emphasizing any challenges you encountered and how you overcame them.

3. Showcase Your Skills and Experience

Highlight your relevant skills, experience, and qualifications that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact. Provide specific examples of projects you have worked on, equipment you have operated, and any certifications or training you have received.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role and the company. Prepare questions about the company’s growth plans, the challenges faced by the Stopboard Assembler team, or any opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Stopboard Assembler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Stopboard Assembler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.