Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stopper Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

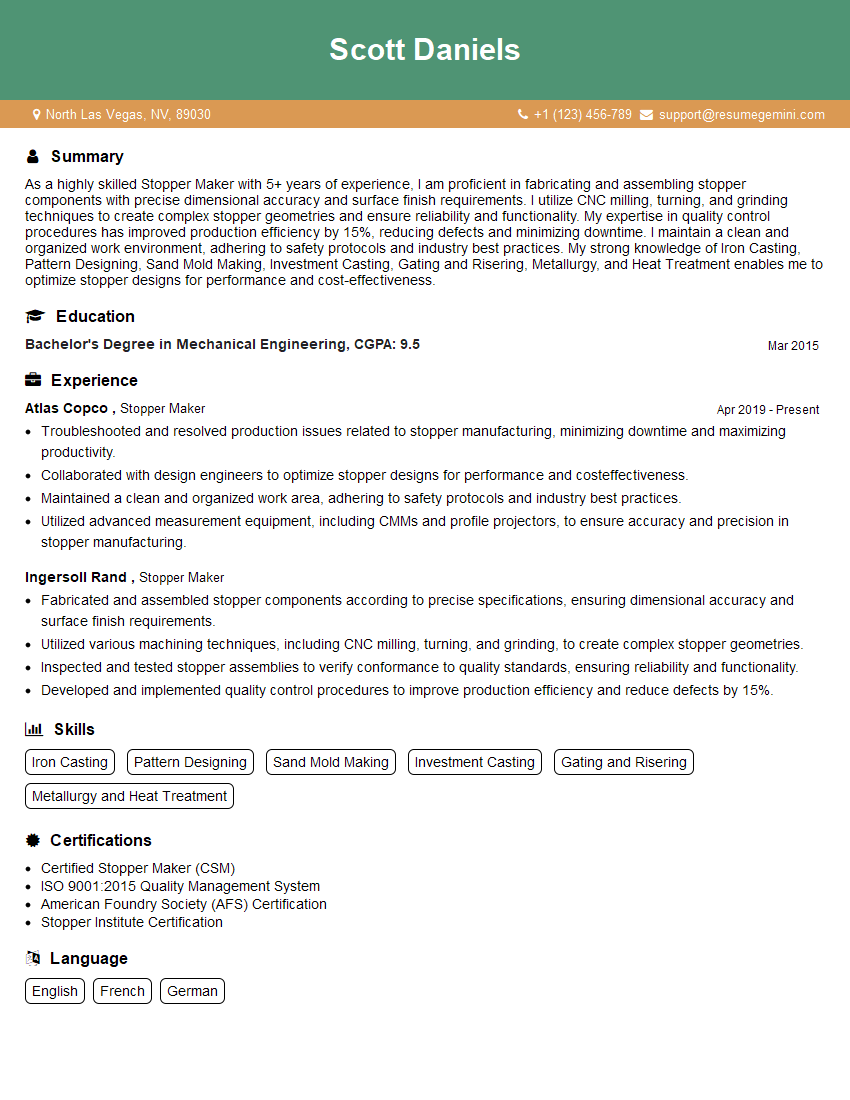

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stopper Maker

1. What are the different types of stoppers used in the industry?

Types of stoppers used in the industry include:

- Cork stoppers: Made from the bark of cork trees, these stoppers are known for their natural elasticity and ability to seal bottles effectively.

- Plastic stoppers: These stoppers are made from various types of plastic materials, offering durability and resistance to chemical degradation.

- Metal stoppers: Metal stoppers are made from materials like aluminum or tin, providing a strong and airtight seal.

- Glass stoppers: Glass stoppers are made from glass and are often used in laboratory settings due to their inertness and resistance to contamination.

- Composite stoppers: These stoppers combine different materials, such as cork and plastic, to achieve specific properties like elasticity and resistance.

2. What are the key factors that determine the quality of a stopper?

Material Quality:

- The quality of the raw materials used in the construction of the stopper significantly impacts its performance and durability.

- Factors such as the density, elasticity, and chemical composition of the material play a crucial role.

Precision and Accuracy:

- The precision and accuracy of the manufacturing process influence the consistency and reliability of the stoppers’ performance.

- Precise dimensions ensure a proper fit and minimize the risk of leakage or contamination.

3. How do you ensure efficient and cost-effective stopper production?

To achieve efficient and cost-effective stopper production, various strategies can be implemented:

- Optimizing raw material selection and sourcing to minimize costs and ensure quality.

- Employing automated manufacturing processes to enhance productivity and reduce labor expenses.

- Implementing quality control measures at every stage to reduce defects and waste.

- Leveraging economies of scale by producing larger batches when possible.

- Exploring innovative production techniques or using alternative materials to reduce costs and improve efficiency.

4. What are the common defects found in stoppers and how do you prevent them?

Common defects in stoppers and preventive measures include:

- Cracks and breaks: Using high-quality materials, proper molding techniques, and careful handling can mitigate these defects.

- Leakage: Ensuring precise dimensions, uniform sealing surfaces, and proper insertion techniques can prevent leakage.

- Contamination: Implementing strict hygiene practices, using clean packaging, and minimizing exposure to potential contaminants are essential.

- Deformation: Utilizing materials with appropriate elasticity and strength, optimizing molding conditions, and providing adequate support during storage can prevent deformation.

- Incompatibility: Selecting stoppers compatible with the specific liquids or gases being stored is crucial to avoid chemical reactions or degradation.

5. What are the latest trends and innovations in stopper technology?

Recent trends in stopper technology focus on:

- Sustainable materials: Exploring environmentally friendly materials like biodegradable or recyclable plastics to reduce environmental impact.

- Advanced sealing mechanisms: Developing stoppers with innovative designs or coatings to enhance sealing performance.

- Smart stoppers: Incorporating sensors or electronic devices into stoppers to monitor conditions like temperature or pressure.

- Anti-counterfeiting measures: Utilizing unique identification or security features to prevent fraud and protect brand reputation.

- Customization: Tailoring stoppers to meet specific requirements, such as custom shapes, sizes, or colors.

6. How do you handle quality control and assurance for stoppers?

Quality control and assurance for stoppers involve:

- Establishing clear specifications and testing protocols for raw materials, production processes, and finished products.

- Implementing statistical process control techniques to monitor and maintain consistent quality.

- Conducting regular inspections and testing to detect defects or deviations from standards.

- Maintaining documentation and traceability throughout the manufacturing process to ensure accountability.

- Receiving feedback from customers and using it to improve product quality and processes.

7. What are the specific industry regulations and standards applicable to stopper production?

Stopper production must adhere to specific industry regulations and standards, including:

- Food and Drug Administration (FDA) regulations for stoppers used in packaging food or pharmaceutical products.

- International Organization for Standardization (ISO) standards for quality management systems, material specifications, and testing methods.

- Industry-specific guidelines and best practices established by organizations like the American Society for Testing and Materials (ASTM).

- Compliance with environmental regulations related to the use of materials and disposal of waste.

8. How do you assess and mitigate risks in stopper production?

Risk assessment and mitigation in stopper production involve:

- Identifying potential risks throughout the production process, such as material defects, equipment malfunctions, or human errors.

- Evaluating the likelihood and severity of each risk to prioritize mitigation efforts.

- Developing and implementing control measures to reduce or eliminate risks, such as supplier qualification, preventive maintenance, and training programs.

- Establishing contingency plans to respond effectively to potential incidents or emergencies.

9. How do you stay updated with advancements and best practices in stopper technology?

To stay updated with advancements and best practices in stopper technology:

- Attend industry conferences and seminars to learn about new products, innovations, and trends.

- Review technical journals and publications for research and developments in the field.

- Collaborate with suppliers, research institutions, and industry experts to exchange knowledge and ideas.

- Actively participate in professional organizations and online forums to stay connected with peers and follow industry discussions.

10. How do you handle customer complaints and ensure customer satisfaction?

To handle customer complaints and ensure customer satisfaction:

- Establish clear channels for customers to voice their concerns and provide feedback.

- Respond promptly and professionally to all complaints, acknowledging the customer’s perspective and taking ownership of any issues.

- Thoroughly investigate the complaint, identify the root cause, and develop appropriate solutions.

- Communicate the resolution to the customer in a timely and transparent manner, addressing their concerns thoroughly.

- Follow up with customers to ensure satisfaction and build long-term relationships.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stopper Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stopper Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stopper Maker plays a crucial role in the manufacturing process, with responsibilities encompassing the design, production, and maintenance of stoppers.

1. Stopper Design and Development

Collaborate with engineers to design and develop stoppers that meet specific requirements, including size, shape, and material composition.

- Analyze customer specifications and provide technical guidance on stopper design.

- Conduct research and testing to optimize stopper performance and ensure compliance with industry standards.

2. Stopper Manufacturing

Operate and maintain stopper-making machinery to produce stoppers in accordance with design specifications.

- Set up and calibrate machinery, ensuring precision and efficiency.

- Monitor production processes, make adjustments, and troubleshoot any issues.

3. Stopper Inspection and Testing

Inspect and test stoppers to ensure they meet quality standards and customer requirements.

- Conduct visual inspections and non-destructive testing to identify defects.

- Maintain accurate records of stopper inspections and test results.

4. Stopper Maintenance and Repair

Perform maintenance and repair work on stopper-making machinery to prevent breakdowns and ensure smooth operation.

- Identify and resolve mechanical issues promptly.

- Conduct preventive maintenance to extend equipment lifespan and minimize downtime.

Interview Tips

To ace the interview for a Stopper Maker position, it’s essential to prepare thoroughly and showcase your relevant skills and experience.

1. Research the Company and Industry

Before the interview, familiarize yourself with the company’s history, culture, and industry. This will demonstrate your interest in the position and the organization.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Highlight Your Technical Skills

Emphasize your knowledge of stopper design, manufacturing, and testing. Provide specific examples of your experience in these areas.

- Quantify your accomplishments, such as the number of stoppers you have designed or tested.

- Describe how you have improved stopper performance or efficiency.

3. Showcase Your Attention to Detail

Stopper Makers require a high level of precision and attention to detail. Provide examples of your meticulous work habits and quality mindset.

- Discuss your experience with using precision instruments and conducting thorough inspections.

- Explain how you maintain and troubleshoot complex equipment.

4. Demonstrate Your Problem-Solving Abilities

The ability to solve problems is crucial in this role. Share examples of how you have identified and resolved issues with stopper design or manufacturing.

- Describe a time when you identified a problem and developed an innovative solution.

- Explain how you have used analytical thinking to troubleshoot and resolve technical issues.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Stopper Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Stopper Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.