Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Stopper Setter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Stopper Setter so you can tailor your answers to impress potential employers.

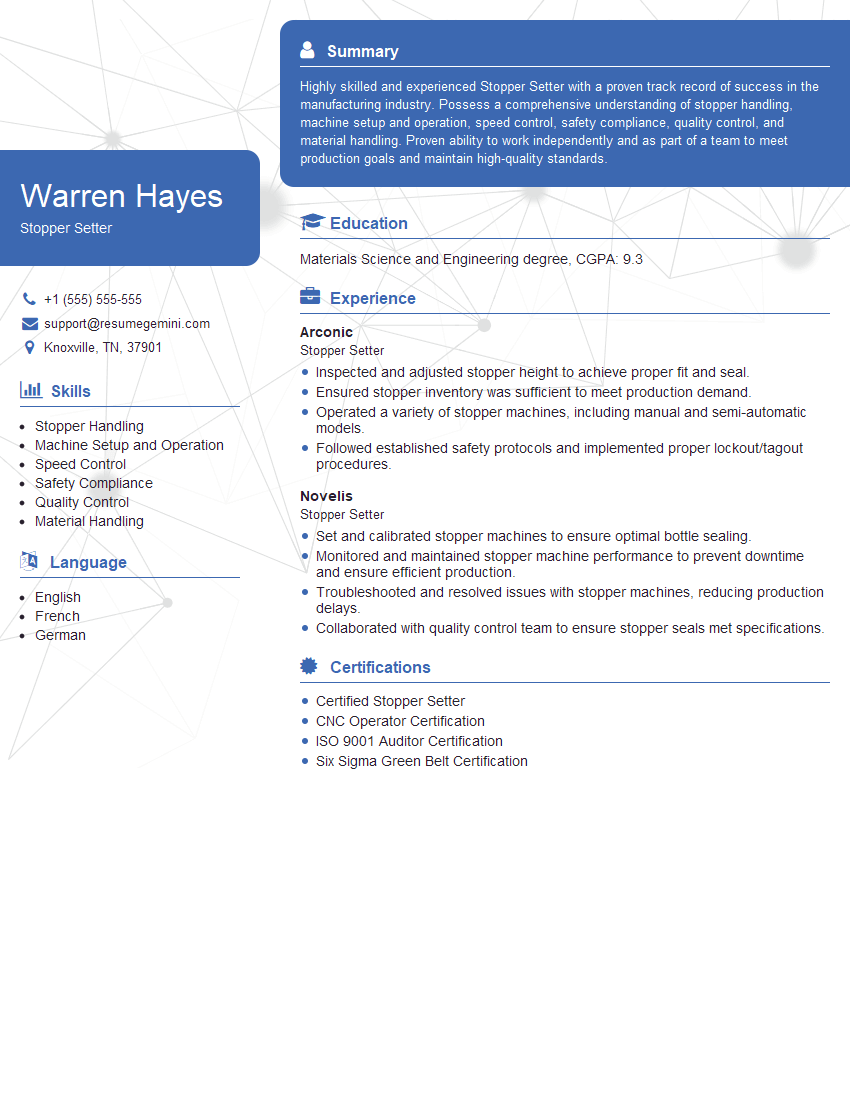

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stopper Setter

1. Describe the key steps involved in setting stoppers in a manufacturing environment.

To set stoppers in a manufacturing environment, I typically follow these key steps:

- Identify the stopper specifications and the equipment required for the job.

- Prepare the machine and set up the necessary tooling, including the stopper mold and mandrel.

- Inspect the stoppers for any defects or irregularities.

- Load the stoppers into the machine.

- Set the machine parameters, including speed, pressure, and temperature.

- Monitor the machine during the setting process to ensure that the stoppers are set correctly.

- Unload the stoppers from the machine and inspect them for any defects.

- Package and label the stoppers for storage or shipment.

2. Explain the different types of stoppers used in manufacturing and their applications.

Rubber Stoppers

- Versatile and can be used in various industries, including pharmaceutical, medical, and laboratory.

- Provide a tight seal and prevent leakage.

Glass Stoppers

- Used in laboratory applications to seal flasks and test tubes.

- Chemically inert and resistant to heat.

Plastic Stoppers

- Lightweight and less expensive than glass stoppers.

- Used in packaging and storage.

Cork Stoppers

- Traditionally used in the wine industry to seal bottles.

- Provide a good seal and allow for aging.

3. Describe the quality control measures you implement while setting stoppers to ensure product quality.

To ensure product quality, I implement the following quality control measures:

- Inspecting stoppers for any defects or irregularities before setting.

- Setting up the machine parameters according to the specified tolerances.

- Monitoring the machine during the setting process to ensure that the stoppers are set correctly.

- Performing regular maintenance and calibration of the machine.

- Inspecting the finished stoppers for any defects.

- Maintaining accurate records of all quality control checks.

4. How do you troubleshoot common problems that may arise during the stopper setting process?

To troubleshoot common problems during the stopper setting process, I typically:

- Identify the problem and its potential causes.

- Check the machine settings and make adjustments as necessary.

- Inspect the stoppers and tooling for any defects or damage.

- Clean and lubricate the machine as needed.

- Restart the machine and monitor it during the setting process.

- If the problem persists, I may consult with a supervisor or maintenance technician for further assistance.

5. Describe the safety protocols you follow when working with stopper setting equipment.

When working with stopper setting equipment, I adhere to the following safety protocols:

- Wearing appropriate personal protective equipment, including safety glasses, gloves, and ear protection.

- Ensuring the machine is properly grounded and electrically safe.

- Keeping the work area clean and free of tripping hazards.

- Following the machine’s operating instructions and safety guidelines.

- Reporting any safety concerns or incidents to a supervisor immediately.

6. Explain how you optimize the stopper setting process to enhance productivity and efficiency.

To optimize the stopper setting process and enhance productivity and efficiency, I employ the following strategies:

- Using automated equipment and pre-setting techniques.

- Minimizing downtime by performing regular maintenance and keeping spare parts on hand.

- Streamlining the workflow and reducing unnecessary steps.

- Training operators on best practices and proper techniques.

- Analyzing production data and identifying areas for improvement.

7. Describe your experience in working with different types of stopper setting machines.

During my experience as a Stopper Setter, I have worked with various types of stopper setting machines, including:

- Semi-automatic machines: These machines require manual loading and unloading of stoppers, but the setting process is automated.

- Fully-automatic machines: These machines automate the entire stopper setting process, including loading, setting, and unloading.

- Handheld stopper setters: These portable devices are used for small-scale or on-site stopper setting.

8. Explain how you handle quality control and inspection procedures to ensure the accuracy and precision of stopper settings.

To ensure the accuracy and precision of stopper settings, I implement the following quality control and inspection procedures:

- Inspecting stoppers for any defects or damage before setting.

- Calibrating the stopper setting machine regularly.

- Setting up the machine parameters according to the specified tolerances.

- Monitoring the machine during the setting process to ensure that the stoppers are set correctly.

- Inspecting the finished stoppers for any defects.

- Maintaining accurate records of all quality control checks.

9. Describe your knowledge of different types of stoppers and their applications in various industries.

I have a comprehensive understanding of different types of stoppers and their applications in various industries, including:

- Rubber stoppers: Used in pharmaceutical, medical, and laboratory applications for sealing vials, bottles, and test tubes.

- Glass stoppers: Used in laboratory applications for sealing flasks and test tubes, providing a chemically inert and airtight seal.

- Plastic stoppers: Used in packaging and storage applications for sealing bottles, jars, and containers.

- Cork stoppers: Traditionally used in the wine industry for sealing bottles and allowing the wine to age.

10. Explain how you maintain a clean and organized work area to ensure the quality and efficiency of stopper setting operations.

Maintaining a clean and organized work area is crucial for the quality and efficiency of stopper setting operations. I implement the following practices:

- Regularly cleaning and disinfecting work surfaces and equipment.

- Storing stoppers and materials in designated areas to prevent contamination.

- Inspecting stoppers for any defects or damage before setting.

- Disposing of waste materials and scrap stoppers promptly.

- Following proper housekeeping procedures to minimize clutter and maintain a safe work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stopper Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stopper Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Stopper Setter, you will be responsible for ensuring the smooth and efficient operation of the stopper setting process in a steel production plant. Your key duties will include:

1. Stopper Setting

Setting and positioning stoppers accurately in the tundish nozzle to control the flow of molten steel during casting.

- Preparing stopper heads and rods for installation.

- Installing stoppers according to specifications.

- Ensuring proper fit and alignment of stoppers.

2. Maintenance and Inspection

Maintaining and inspecting stopper setting equipment, including tundishes, nozzles, and stopper rods.

- Cleaning and lubricating equipment.

- Inspecting for wear and damage.

- Making necessary repairs and adjustments.

3. Quality Control

Monitoring and controlling the stopper setting process to ensure the quality of molten steel production.

- Monitoring flow rates and temperatures.

- Adjusting stopper settings as needed.

- Preventing leaks and spills.

4. Safety and Compliance

Adhering to safety regulations and operating procedures.

- Wearing appropriate personal protective equipment.

- Following established safety protocols.

- Reporting potential hazards.

Interview Tips

To prepare for your interview as a Stopper Setter, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s website, recent news articles, and industry trends. This will demonstrate your interest and knowledge of the field.

2. Practice Common Interview Questions

Review common interview questions such as “Tell me about yourself” and “Why are you interested in this role?”. Prepare concise and well-thought-out answers that highlight your relevant skills and experience.

3. Emphasize Relevant Skills

During the interview, focus on showcasing your expertise in stopper setting, maintenance, and quality control. Provide specific examples of your accomplishments and how they have contributed to successful steel production.

4. Be Prepared to Discuss Safety

Safety is paramount in steel production. Be ready to discuss your commitment to following safety protocols, identifying potential hazards, and ensuring a safe work environment.

5. Ask Questions

At the end of the interview, take the opportunity to ask questions about the role and the company. This shows your engagement and interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stopper Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!