Are you gearing up for an interview for a Straight Bevel Gear Generator Set-Up Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Straight Bevel Gear Generator Set-Up Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

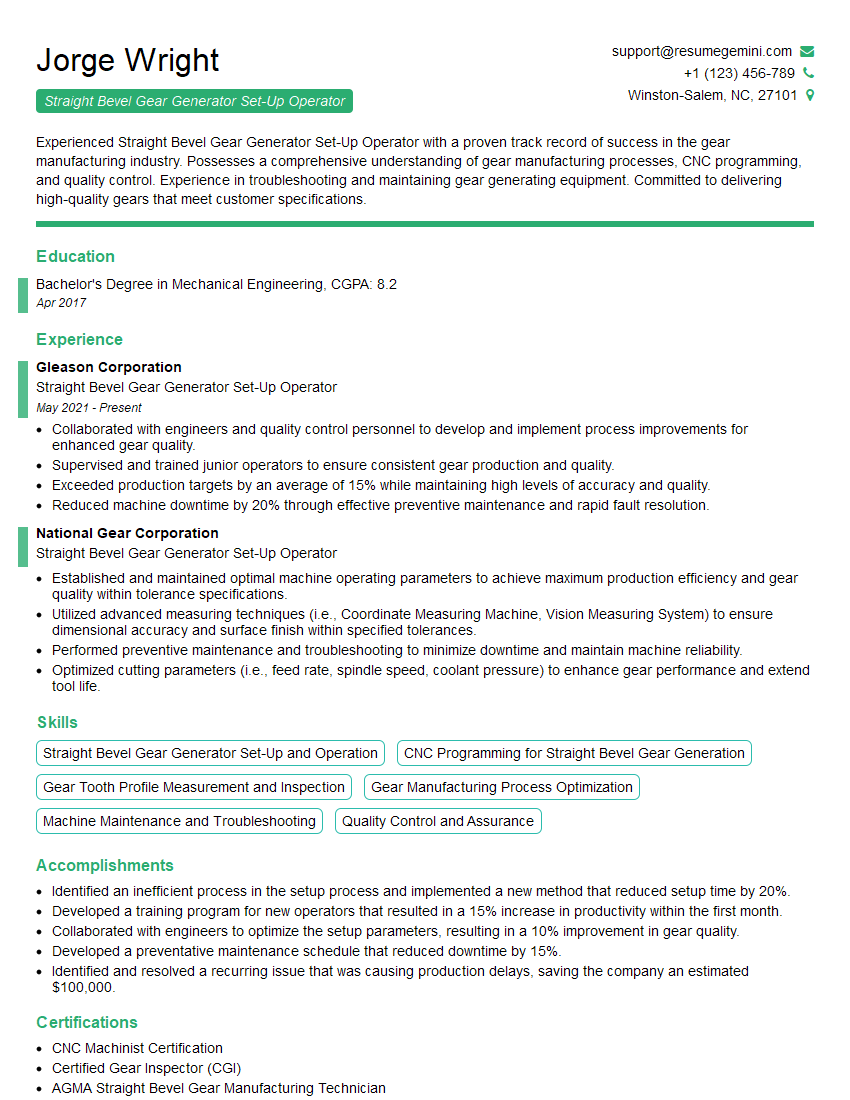

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Straight Bevel Gear Generator Set-Up Operator

1. Describe the process involved in setting up a straight bevel gear generator.

- Inspect the incoming gears for any defects.

- Mount the gears on the machine.

- Set the machine parameters, such as the cutting speed, feed rate, and depth of cut.

- Run the machine to cut the gears.

- Inspect the finished gears for any defects.

2. What are the different types of straight bevel gears?

- Spiral bevel gears

- Zerol bevel gears

- Hypoid gears

3. What are the advantages and disadvantages of straight bevel gears?

Advantages

- High strength and durability

- Smooth and quiet operation

- Compact size

Disadvantages

- Limited speed capacity

- Susceptible to wear and tear

- Can be expensive to manufacture

4. What are the common applications of straight bevel gears?

- Automotive differentials

- Industrial machinery

- Aerospace applications

5. What are the key factors to consider when setting up a straight bevel gear generator?

- The type of gear being cut

- The material of the gear

- The cutting speed

- The feed rate

- The depth of cut

- The machine settings

6. What are the common problems that can occur when setting up a straight bevel gear generator?

- Gear chatter

- Gear tooth breakage

- Gear wear

- Machine downtime

7. What are the preventive maintenance tasks that should be performed on a straight bevel gear generator?

- Regularly cleaning and lubricating the machine

- Inspecting the gears for wear and tear

- Calibrating the machine

- Replacing worn or damaged parts

8. What are the safety precautions that should be taken when operating a straight bevel gear generator?

- Wearing appropriate safety gear

- Keeping the work area clean and free of debris

- Following the manufacturer’s instructions

- Being aware of the potential hazards

9. What are the troubleshooting tips for a straight bevel gear generator?

- If the gears are chattering, check the cutting speed, feed rate, and depth of cut.

- If the gears are breaking, check the material of the gears and the cutting parameters.

- If the gears are wearing, check the lubrication and the machine settings.

- If the machine is down, check the power supply, the hydraulic system, and the electrical system.

10. What are the latest trends in straight bevel gear generator technology?

- Computer-aided manufacturing (CAM)

- Automated tool changers

- High-speed cutting

- Advanced materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Straight Bevel Gear Generator Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Straight Bevel Gear Generator Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Straight Bevel Gear Generator Set-Up Operator is entrusted with the responsibility of setting up and operating a Straight Bevel Gear Generator machine. Their primary role is to ensure the precision and accuracy of the bevel gears produced by the machine, meeting the specified requirements and industry standards.

1. Machine Set-Up and Operation

The operator ensures the proper set-up and configuration of the Straight Bevel Gear Generator machine. This involves:

- Installing and aligning cutting tools, such as cutters and hobs, according to the gear specifications.

- Setting machine parameters, including cutting speed, feed rate, and depth of cut, based on the workpiece material and gear design.

- Performing trial cuts and making necessary adjustments to optimize cutting conditions and achieve desired gear quality.

2. Monitoring and Process Control

The operator closely monitors the cutting process and machine operation during production. This includes:

- Observing cutting tool wear and making adjustments to maintain cutting efficiency and gear quality.

- Checking workpiece dimensions and surface finish against specifications using measuring instruments.

- Monitoring machine sensors and alarms to identify potential issues and take corrective action to prevent machine damage or production downtime.

3. Quality Control and Inspection

The operator ensures the quality of the produced bevel gears by performing inspections and adhering to quality standards. This involves:

- Conducting visual inspections of gears for defects, such as nicks, burrs, or surface imperfections.

- Using measuring equipment, such as gear tooth gauges and micrometers, to verify gear dimensions, tooth profiles, and tolerances.

- Maintaining inspection records to document gear quality and adherence to specifications.

4. Maintenance and Troubleshooting

The operator is responsible for performing basic maintenance and troubleshooting tasks to ensure optimal machine performance and prevent downtime. This includes:

- Cleaning and lubricating the machine and its components regularly.

- Identifying and addressing minor machine issues, such as tool wear or sensor malfunctions.

- Reporting any major issues or maintenance needs to supervisors or maintenance personnel.

Interview Tips

To prepare for an interview as a Straight Bevel Gear Generator Set-Up Operator, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and industry trends. This demonstrates your interest and knowledge of the field, which can impress interviewers.

- Visit the company’s website to learn about their history, mission, and values.

- Read industry news and articles to stay updated on current trends and technologies.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities. Quantify your accomplishments whenever possible to demonstrate your impact.

- Highlight your proficiency in setting up and operating Straight Bevel Gear Generator machines.

- Provide examples of how you have successfully monitored and controlled cutting processes to achieve desired gear quality.

3. Prepare for Technical Questions

Interviews for this role often involve technical questions to assess your knowledge and understanding of the equipment and processes involved. Be prepared to answer questions on:

- Types of cutting tools used in bevel gear generation and their applications.

- Factors affecting gear quality, such as cutting speed, feed rate, and tool wear.

- Inspection methods and equipment used for gear quality control.

4. Demonstrate Problem-Solving Abilities

Employers value candidates who can effectively solve problems and make decisions. Provide examples of how you have identified and resolved issues in previous roles.

- Describe a situation where you encountered a problem with the gear generator machine and how you diagnosed and fixed it.

- Explain how you handled production delays due to unexpected issues and implemented measures to minimize downtime.

5. Ask Informed Questions

Asking relevant questions during the interview shows your interest and engagement. Prepare questions about the company’s production processes, quality standards, or career advancement opportunities.

- Ask about the company’s quality control procedures to ensure customer satisfaction.

- Inquire about opportunities for training and development to enhance your skills in the field.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Straight Bevel Gear Generator Set-Up Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Straight Bevel Gear Generator Set-Up Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.