Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Straightener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

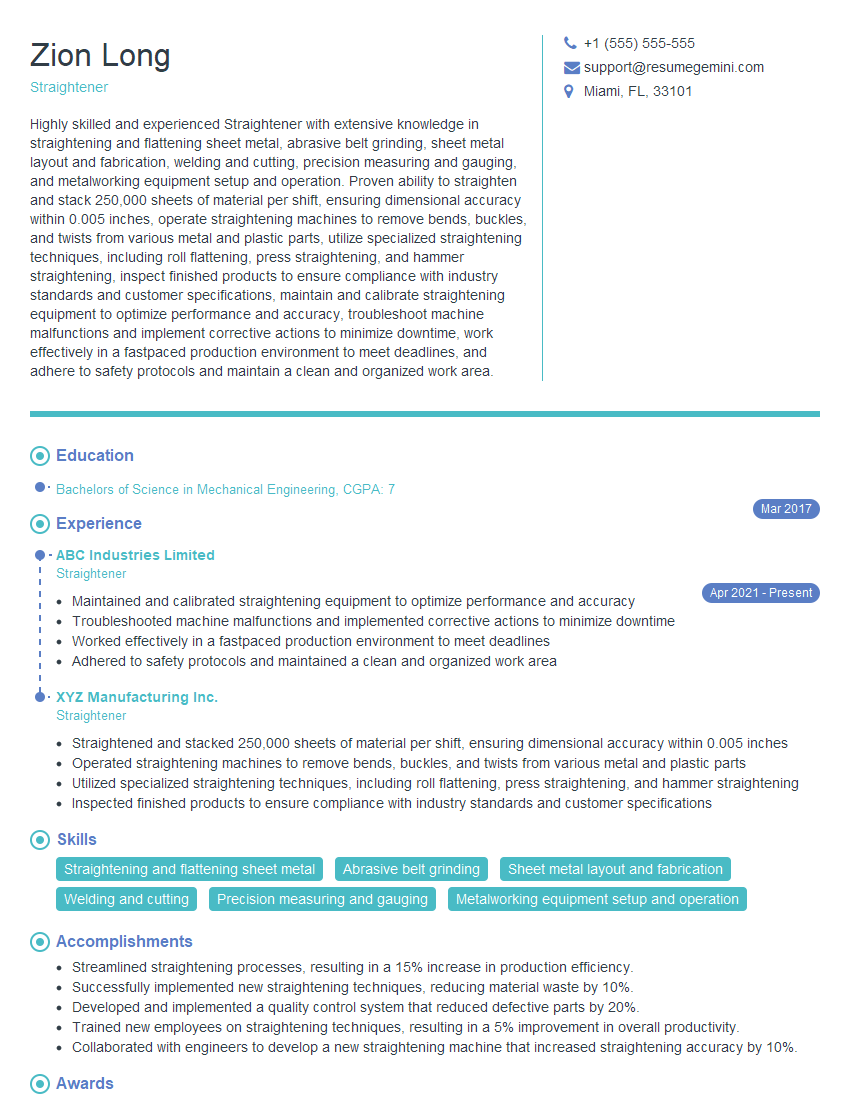

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Straightener

1. Describe the key responsibilities of a Straightener in a steel mill?

A Straightener in a steel mill is responsible for the following key tasks:

- Operate and maintain straightening machines to remove bends and kinks from steel bars, rods, and other metal products.

- Inspect raw materials and finished products to ensure they meet specifications.

- Adjust and calibrate straightening machines to achieve desired results.

- Troubleshoot and repair straightening machines as needed.

- Maintain a clean and safe work area.

2. What are the different types of straightening machines used in a steel mill?

- Roller straighteners: Use a series of rollers to apply pressure on the material and remove bends and kinks.

- Pinch roll straighteners: Use a pair of pinch rolls to grip the material and pull it through a series of straightening dies.

- Levelers: Use a series of leveling rolls to flatten and straighten sheet metal.

3. What are the key factors to consider when selecting the right straightening machine for a particular job?

- Material type: Different materials have different properties that affect the straightening process.

- Material thickness: The thickness of the material will determine the size and capacity of the straightening machine required.

- Material width: The width of the material will determine the width of the straightening machine.

- Desired straightness: The desired straightness will determine the type of straightening machine and the settings required.

4. How do you ensure the accuracy and precision of a straightening machine?

- Regular calibration: Straightening machines should be calibrated regularly to ensure accuracy.

- Proper maintenance: Straightening machines should be properly maintained to ensure they are operating at peak performance.

- Operator training: Operators should be properly trained on how to use and adjust straightening machines.

5. What are the potential hazards associated with operating a straightening machine, and how do you mitigate them?

- Pinch points: Straightening machines have pinch points where the material is gripped and pulled through the machine. Operators should wear appropriate safety gear and keep their hands clear of these pinch points.

- Flying debris: Straightening machines can generate flying debris, which can be hazardous to operators and others in the area. Operators should wear appropriate safety gear and ensure that the area around the machine is clear of debris.

- Noise: Straightening machines can generate noise, which can be hazardous to operators and others in the area. Operators should wear appropriate hearing protection.

6. What are the latest advancements in straightening technology, and how have they impacted the industry?

- Computer-controlled straightening machines: Computer-controlled straightening machines offer greater precision and control than manual straightening machines.

- Laser-based straightening systems: Laser-based straightening systems use lasers to measure and correct material defects.

- Automated straightening lines: Automated straightening lines combine multiple straightening machines into a single, automated system.

7. How do you stay up-to-date on the latest advancements in straightening technology?

- Attend industry conferences and trade shows: Industry conferences and trade shows provide opportunities to learn about the latest advancements in straightening technology.

- Read industry publications: Industry publications provide information on the latest advancements in straightening technology.

- Network with other professionals: Networking with other professionals in the industry can provide valuable insights into the latest advancements in straightening technology.

8. What are your strengths and weaknesses as a Straightener?

-

Strengths:

- Strong attention to detail

- Ability to operate and maintain a variety of straightening machines

- Excellent troubleshooting skills Weaknesses:

- Limited experience with computer-controlled straightening machines

- Need to improve time management skills

9. Why are you interested in this Straightener position?

I am interested in this Straightener position because I am passionate about the steel industry and I believe that my skills and experience would be a valuable asset to your team. I am confident that I can make a significant contribution to your company.

10. How do you see your role as a Straightener evolving in the future?

I believe that the role of a Straightener will continue to evolve in the future as technology advances. I am eager to learn about new straightening technologies and to develop my skills in this area. I am also interested in exploring opportunities to move into management or supervision.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Straightener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Straightener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Straighteners play a crucial role in ensuring the precision and quality of metal and plastic parts in manufacturing industries. Their key job responsibilities include:1. Straightening and Forming: Straighteners are responsible for straightening bent or warped metal and plastic parts using specialized equipment, such as straightening presses, hydraulic presses, and bending machines. They ensure that parts conform to precise specifications and meet quality standards.

2. Quality Control and Inspection: Straighteners conduct thorough inspections of straightened parts to ensure they meet the desired shape, dimensions, and tolerances. They may use measuring tools, gauges, and other instruments to verify accuracy and prevent defects.

3. Machine Operation and Maintenance: Straighteners operate and maintain straightening equipment, including presses, bending machines, and hydraulic systems. They perform routine maintenance tasks, such as lubrication, calibration, and troubleshooting, to ensure optimal performance and prevent breakdowns.

4. Process Optimization: Straighteners analyze production processes and identify areas for improvement. They suggest modifications to equipment, procedures, and workflows to optimize efficiency, reduce waste, and enhance product quality.

5. Safety Compliance: Straighteners strictly adhere to safety regulations and protocols in the workplace. They wear appropriate personal protective equipment (PPE), follow established procedures, and maintain a clean and organized work area to prevent accidents and injuries.

Interview Tips

To ace an interview for the role of a Straightener, it is essential to prepare thoroughly and demonstrate your skills and abilities effectively. Here are some tips to help you make a positive impression:

1. Research the Company and Position: Learn about the company’s history, products/services, and industry standing. Research the specific responsibilities of the Straightener role and identify how your skills align with them.

2. Highlight Your Technical Expertise: Emphasize your knowledge of straightening techniques, equipment operation, and quality control procedures. Explain your experience in using different types of straightening machines and your ability to work with a variety of metal and plastic materials.

3. Showcase Your Problem-Solving Abilities: Describe situations where you identified and resolved issues related to straightening or quality control. Explain the steps you took to analyze the problem, develop solutions, and achieve positive outcomes.

4. Demonstrate Attention to Detail: Straightening requires meticulous attention to detail. Highlight your ability to perform precise measurements, verify dimensions, and ensure that parts meet stringent specifications.

5. Emphasize Safety and Compliance: Explain your commitment to workplace safety and compliance with regulations. Describe your experience in adhering to PPE protocols, maintaining a clean work area, and preventing accidents.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Straightener role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.