Feeling lost in a sea of interview questions? Landed that dream interview for Straightening Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Straightening Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

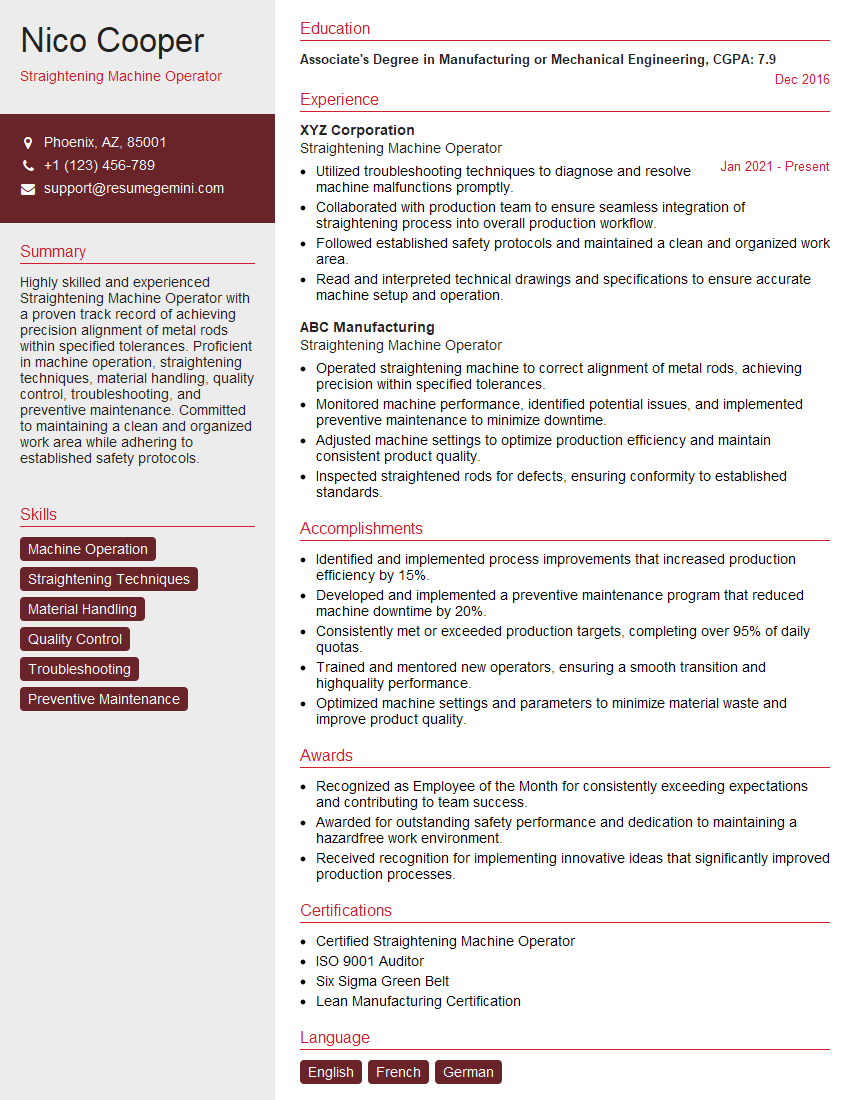

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Straightening Machine Operator

1. Describe the process of straightening metal using a straightening machine?

The process of straightening metal using a straightening machine involves the following steps:

- The metal is fed into the machine, typically through a set of rollers.

- The metal is then passed through a series of straightening rolls, which are arranged in a specific pattern to apply pressure and bend the metal back into shape.

- The straightened metal is then ejected from the machine.

2. What are the different types of straightening machines?

There are two main types of straightening machines: roller straighteners and press straighteners.

Roller straighteners:

- Use a series of rollers to apply pressure and bend the metal back into shape.

- Are typically used for straightening long, thin pieces of metal.

Press straighteners:

- Use a press to apply pressure and bend the metal back into shape.

- Are typically used for straightening thicker, shorter pieces of metal.

3. What are the factors that affect the straightening process?

The straightening process is affected by several factors, including:

- The type of metal being straightened

- The thickness of the metal

- The length of the metal

- The speed of the straightening machine

- The temperature of the metal

4. What are the common problems that can occur during the straightening process?

Common problems that can occur during the straightening process include:

- The metal is not straightened properly.

- The metal is damaged during the straightening process.

- The straightening machine breaks down.

5. How can problems during the straightening process be prevented?

Problems during the straightening process can be prevented by:

- Properly maintaining the straightening machine

- Using the correct settings for the straightening machine

- Inspecting the metal before and after the straightening process

6. What are the safety precautions that should be taken when operating a straightening machine?

The following safety precautions should be taken when operating a straightening machine:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is damaged.

- Follow all manufacturer instructions.

7. What are the maintenance procedures that should be performed on a straightening machine?

The following maintenance procedures should be performed on a straightening machine:

- Clean the machine regularly.

- Lubricate the machine regularly.

- Inspect the machine for damage regularly.

- Follow all manufacturer maintenance instructions.

8. What are the troubleshooting procedures that can be performed on a straightening machine?

The following troubleshooting procedures can be performed on a straightening machine:

- Check the power supply.

- Check the fuses.

- Check the belts.

- Check the rollers.

- Check the hydraulic system.

9. What are the skills and experience required to be a straightening machine operator?

The skills and experience required to be a straightening machine operator include:

- Experience operating a straightening machine

- Knowledge of the straightening process

- Ability to read and interpret blueprints

- Ability to work independently

- Ability to work in a team environment

10. What are the career opportunities for straightening machine operators?

The career opportunities for straightening machine operators include:

- Straightening machine operator

- Straightening machine supervisor

- Quality control inspector

- Production manager

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Straightening Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Straightening Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Straightening Machine Operators play a crucial role in maintaining the precision and quality of metal products by operating and monitoring straightening machines. Their responsibilities include:

1. Machine Operation

Performing straightening operations on metal rods, tubes, or wires using straightening machines.

- Setting up and adjusting straightening machines for different material types and dimensions.

- Operating straightening machines safely and efficiently to achieve desired results.

2. Material Handling

Handling and loading metal materials into and out of straightening machines.

- Inspecting materials for defects and damage.

- Ensuring proper material feeding and positioning during straightening operations.

3. Measurement and Quality Control

Checking the straightness of materials using measuring instruments and gauges.

- Monitoring straightening processes to ensure compliance with specifications.

- Reporting any deviations or defects to supervisors.

4. Equipment Maintenance

Performing basic maintenance on straightening machines.

- Cleaning and lubricating machine components.

- Reporting any maintenance issues or malfunctions to supervisors.

Interview Tips

To ace the interview for a Straightening Machine Operator position, it’s essential to prepare thoroughly to present your skills and experience effectively. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, values, and the specific role you’re applying for.

- Visit the company website and social media pages.

- Read industry news and articles to stay informed about current trends.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience that are most relevant to the job description.

- Quantify your accomplishments whenever possible.

- Use specific examples to demonstrate your proficiency in operating straightening machines and ensuring quality control.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation for applying for the position.

- Draft answers that showcase your knowledge, enthusiasm, and ability to handle the responsibilities of the role.

- Consider using the STAR method (Situation, Task, Action, Result) to provide clear and concise answers.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company.

- Questions about the company’s culture, growth opportunities, and safety protocols are appropriate.

- Inquire about any specific challenges or projects that the department is currently facing.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview.

- Choose clean and pressed attire that is appropriate for a manufacturing environment.

- Plan your route in advance to avoid delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Straightening Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!