Are you gearing up for a career in Stretch Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Stretch Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

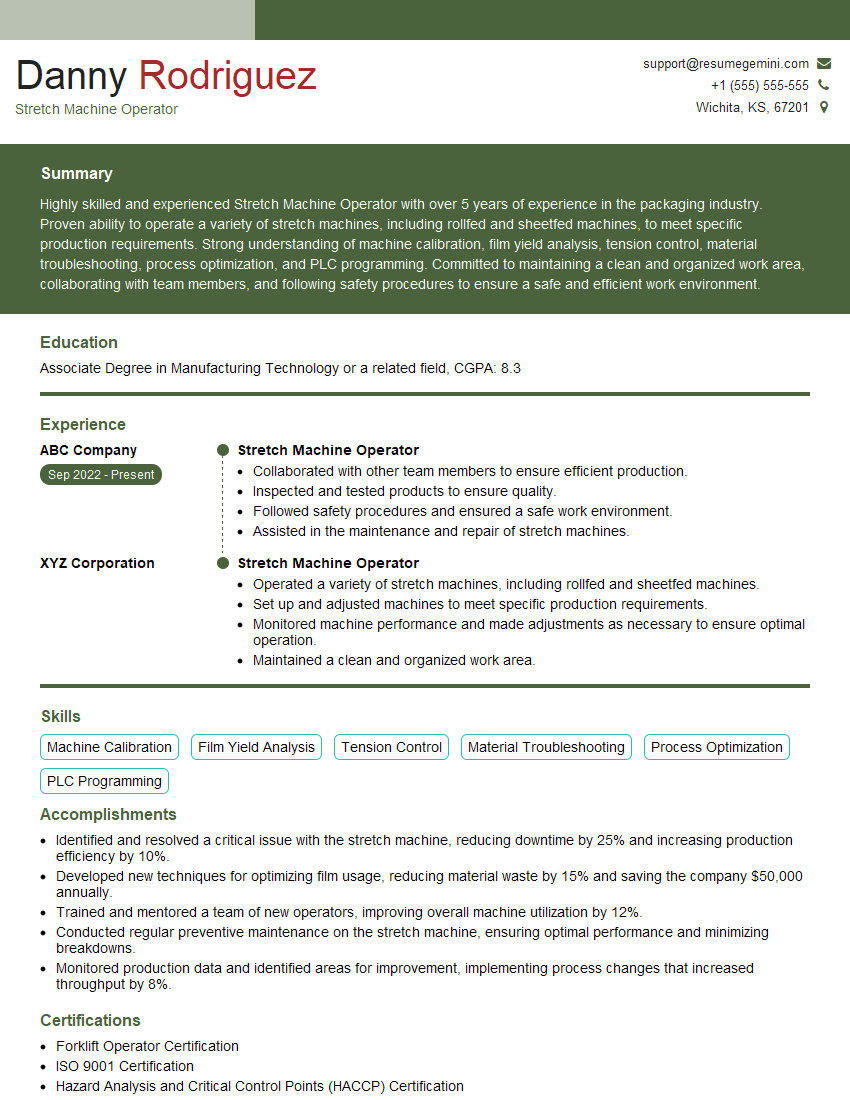

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stretch Machine Operator

1. Describe the process of film wrapping using a stretch machine?

The film wrapping process using a stretch machine involves several key steps:

- Load the film: The stretch film roll is loaded onto the machine’s dispenser.

- Adjust the tension: The tension of the film is adjusted to ensure proper wrapping and stability.

- Start the machine: The machine is started, and the film is fed through a rotating arm.

- Wrap the product: The product is placed on the wrapping table, and the film is wrapped around it multiple times.

- Seal the film: Once the desired number of wraps is achieved, the film is sealed using a heat sealer or adhesive tape.

- Unload the wrapped product: The wrapped product is removed from the table, and the process is repeated for the next product.

2. Explain how to troubleshoot common issues with a stretch machine, such as film breakage or incorrect tension?

Troubleshooting film breakage

- Check if the film is loaded correctly and has no cuts or tears.

- Inspect the rollers and guides for any damage or obstructions.

- Adjust the film tension to ensure it is not too tight or too loose.

- Examine the heat sealer or adhesive system for proper functioning.

Troubleshooting incorrect tension

- Verify the tension settings on the machine’s control panel.

- Check if the film is stretched evenly during the wrapping process.

- Inspect the tensioning rollers for wear or damage.

- Calibrate the machine according to the manufacturer’s instructions.

3. How do you ensure that the wrapped products meet the required specifications and quality standards?

To ensure that the wrapped products meet the required specifications and quality standards, I follow these practices:

- Understand product requirements: Review the specifications and standards for the products being wrapped.

- Inspect products before wrapping: Check for any defects or damage that could affect the wrapping process.

- Select appropriate film: Choose the correct type and thickness of film to provide the necessary protection and stability.

- Monitor machine settings: Ensure that the machine’s tension, speed, and other settings are optimized for the products.

- Inspect wrapped products: Visually check the wrapped products to ensure they are adequately protected and meet the desired quality.

4. Describe your experience in maintaining and repairing stretch machines?

Throughout my experience as a Stretch Machine Operator, I have actively participated in maintaining and repairing stretch machines. My responsibilities included:

- Regular maintenance: Performed routine inspections, cleaning, and lubrication to ensure smooth operation.

- Troubleshooting: Identified and resolved common issues such as film breakage, incorrect tension, and electrical faults.

- Minor repairs: Replaced worn or damaged components, such as rollers, belts, and sensors.

- Collaborated with technicians: Assisted with major repairs and overhauls, following the manufacturer’s guidelines.

5. Explain the importance of safety precautions when operating a stretch machine?

Safety precautions are paramount when operating a stretch machine to prevent accidents and ensure the well-being of the operator and those around.

- Wear appropriate PPE: Use gloves, safety glasses, and proper footwear to protect against potential hazards.

- Inspect the machine: Before each operation, check the machine for any damage or malfunctions.

- Clear the area: Ensure that the work area is free of tripping hazards and obstructions.

- Follow instructions: Operate the machine according to the manufacturer’s instructions and established safety protocols.

- Stay alert: Pay attention to the machine’s operation and be aware of potential risks.

6. How do you manage multiple tasks and prioritize your responsibilities as a Stretch Machine Operator?

In my role as a Stretch Machine Operator, I effectively manage multiple tasks and prioritize my responsibilities to ensure smooth operations.

- Plan ahead: Anticipate the upcoming tasks and prepare accordingly.

- Prioritize tasks: Determine the most important and time-sensitive tasks based on production schedules and deadlines.

- Delegate: If possible, assign tasks to other team members when appropriate.

- Stay organized: Maintain a clean and organized work area to minimize distractions.

- Seek support: Do not hesitate to ask for assistance from supervisors or colleagues when needed.

7. Describe the role of maintenance in ensuring the productivity and efficiency of stretch machines?

Regular maintenance is crucial for maintaining the productivity and efficiency of stretch machines.

- Preventative maintenance: Following a scheduled maintenance plan helps identify and address potential issues before they cause major breakdowns.

- Reduced downtime: Proactive maintenance minimizes the likelihood of unexpected machine failures, reducing downtime and increasing productivity.

- Extended equipment life: Proper maintenance extends the lifespan of stretch machines, providing a longer period of optimal performance.

- Improved product quality: Well-maintained machines consistently produce high-quality wrapped products.

- Safety: Regular maintenance ensures that machines operate safely, reducing the risk of accidents.

8. Explain how lean manufacturing principles can be applied to optimize stretch machine operations?

Lean manufacturing principles aim to eliminate waste and inefficiencies in production processes.

- Identify waste: Analyze stretch machine operations to identify areas of waste, such as unnecessary movement, overproduction, and waiting.

- Reduce waste: Implement solutions to eliminate or minimize identified waste, such as streamlining work processes and reducing setup times.

- Continuous improvement: Regularly monitor and evaluate stretch machine operations to identify further opportunities for improvement.

- Employee involvement: Engage employees in the lean improvement process to gather their insights and ideas.

- Focus on value: Prioritize activities and processes that add value to the wrapping process and customer satisfaction.

9. Discuss the environmental impact of stretch film and explore sustainable alternatives that a Stretch Machine Operator can implement?

Stretch film can have an environmental impact due to its plastic composition.

- Reduce film usage: Optimize machine settings and wrapping techniques to minimize the amount of film used.

- Use recycled film: Opt for stretch film made from recycled materials to reduce the consumption of virgin plastics.

- Explore biodegradable alternatives: Research and consider biodegradable or compostable stretch film options.

- Proper waste disposal: Ensure that used stretch film is disposed of responsibly through recycling programs or waste management services.

10. Describe your approach to training and development as a Stretch Machine Operator?

To stay updated and enhance my skills as a Stretch Machine Operator, I focus on continuous training and development.

- Attend training programs: Participate in training opportunities provided by the company or external organizations.

- Study technical manuals: Thoroughly review machine manuals and technical documentation to gain in-depth knowledge.

- Seek mentorship: Identify experienced operators or supervisors who can provide guidance and share their expertise.

- Stay informed: Keep abreast of industry best practices, new technologies, and advancements in stretch machine operations.

- Share knowledge: Actively participate in knowledge sharing sessions and train new operators to promote a collaborative learning environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stretch Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stretch Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stretch Machine Operator operates and maintains a machine that stretches plastic film. The operator is responsible for setting up the machine, loading it with raw materials, and monitoring its operation. They also perform quality checks on the finished product and make adjustments to the machine as needed.

1. Set up and operate the stretch machine

The operator must be able to set up the machine according to the manufacturer’s instructions. This includes loading the machine with raw materials, such as plastic film, and setting the machine’s parameters, such as the speed and temperature.

- Operate the stretch machine according to standard operating procedures

- Monitor the machine’s operation and make adjustments as needed

2. Inspect the finished product

The operator must be able to inspect the finished product to ensure that it meets quality standards. This includes checking the product for defects, such as holes, tears, or wrinkles.

- Inspect the finished product for defects

- Reject any products that do not meet quality standards

3. Maintain the stretch machine

The operator is responsible for maintaining the stretch machine in good working condition. This includes cleaning the machine, lubricating its parts, and making minor repairs.

- Clean the machine

- Lubricate the machine’s parts

- Make minor repairs

4. Follow safety procedures

The operator must follow all safety procedures when operating the stretch machine. This includes wearing appropriate safety gear, such as gloves and safety glasses, and following lockout/tagout procedures.

- Wear appropriate safety gear

- Follow lockout/tagout procedures

Interview Tips

Preparing for an interview for a Stretch Machine Operator position can be a daunting task, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Prepare examples of your skills and experience

- Practice your answers with a friend or family member

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Wear business attire

- Be punctual

- Be polite and respectful

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position, and to show the interviewer that you are engaged and interested.

- Prepare a list of questions to ask the interviewer

- Ask thoughtful questions that show your interest in the company and the position

- Be prepared to answer questions about your experience and qualifications

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Stretch Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.