Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Stretcher-Leveler Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Stretcher-Leveler Operator so you can tailor your answers to impress potential employers.

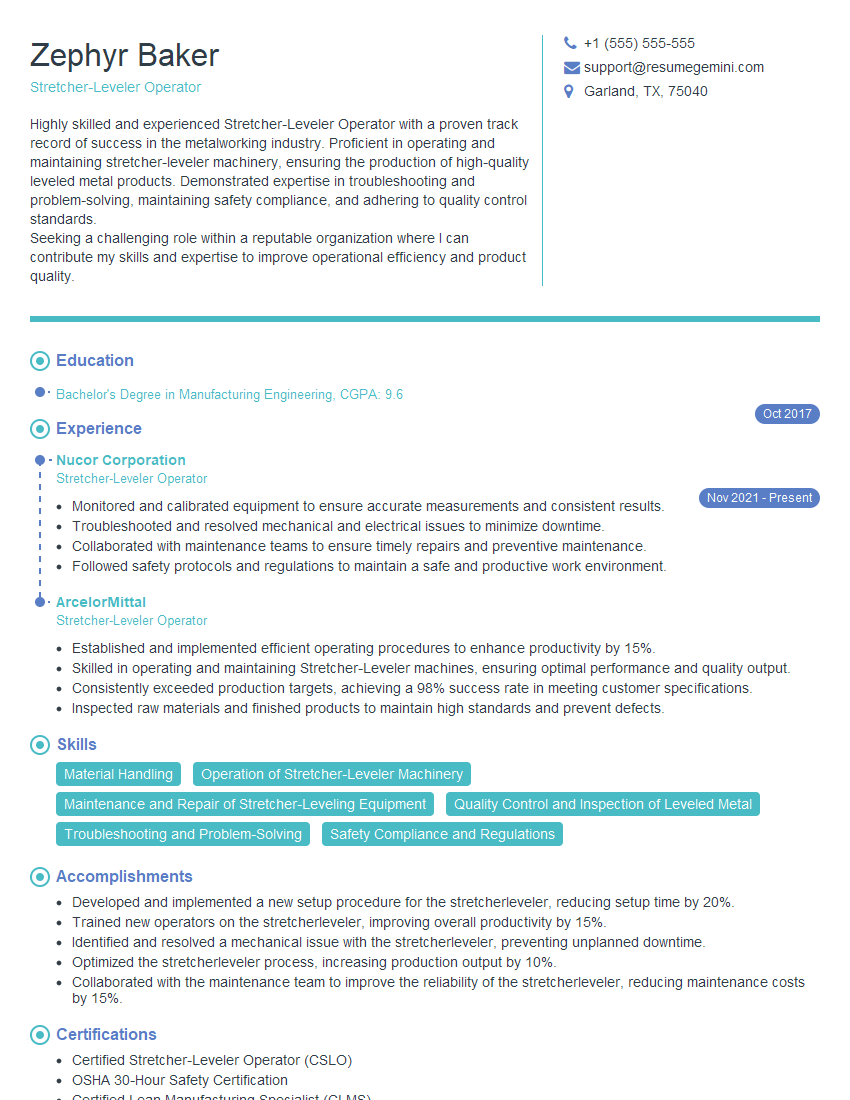

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stretcher-Leveler Operator

1. What are the primary responsibilities of a Stretcher-Leveler Operator?

- Operate and monitor stretcher-leveler machines to level and remove buckles from metal coils.

- Adjust machine settings, including tension, speed, and roll gap, to ensure optimal leveling results.

2. Describe the different types of stretcher-leveler machines and their capabilities.

Hydraulic Stretchers

- Use hydraulic cylinders to apply tension to the metal coil.

- Suitable for leveling thin and delicate materials.

Mechanical Stretchers

- Use mechanical components, such as gears and shafts, to apply tension.

- Can handle thicker and heavier materials.

Pneumatic Stretchers

- Use compressed air to apply tension.

- Offer fast leveling speeds and require less maintenance.

3. How do you determine the appropriate tension and speed settings for a given material?

- Refer to manufacturer’s recommendations and material specifications.

- Inspect the material for its thickness, hardness, and yield strength.

- Start with conservative settings and gradually adjust until the desired leveling is achieved.

4. How do you troubleshoot common problems with stretcher-leveler machines?

- Inspect for mechanical issues, such as loose belts or worn bearings.

- Check electrical connections and ensure proper voltage supply.

- Monitor sensors and gauges to identify any deviations in pressure, tension, or speed.

5. What safety precautions are essential when operating a stretcher-leveler machine?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Be aware of potential pinch points and keep hands clear of moving parts.

6. How do you maintain and calibrate stretcher-leveler machines?

Maintenance

- Regularly lubricate moving parts.

- Inspect and replace worn components.

- Clean and maintain sensors and gauges.

Calibration

- Use specialized equipment to verify accuracy of tension and speed measurements.

- Adjust sensors and settings as necessary to ensure optimal performance.

- Maintain calibration records for traceability and quality control purposes.

7. What is the role of tension in stretcher leveling?

- Tension provides the force necessary to stretch and level the metal.

- Proper tension helps minimize springback and ensures consistent flattening.

- Excessive tension can cause tearing or distortion, while insufficient tension may result in uneven leveling.

8. How do you ensure that the leveled metal meets the required flatness specifications?

- Use measuring tools, such as micrometers and dial gauges, to verify flatness.

- Compare results to customer requirements and industry standards.

- Adjust machine settings and tension as needed to achieve the desired flatness.

9. What is the importance of proper roll gap adjustment?

- Roll gap determines the amount of pressure applied to the metal.

- Too wide of a gap can result in insufficient leveling, while too narrow of a gap can cause damage to the material.

- Proper adjustment ensures optimal leveling results and minimizes material waste.

10. How do you handle deviations from the desired leveling results?

- Inspect the material and machine settings to identify the cause of the deviation.

- Adjust tension, speed, or roll gap as necessary.

- If the problem persists, consult with a supervisor or technician for further assistance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stretcher-Leveler Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stretcher-Leveler Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The key job responsibilities of a Stretcher-Leveler Operator include the following:

1. Operate Stretcher-Leveler Equipment

Operate stretcher-leveler equipment to straighten and smooth metal sheets or coils.

- Configure the stretcher-leveler machine based on the metal’s properties and desired specifications.

- Thread the metal through the machine and adjust tension and speed settings to ensure proper processing.

2. Monitor and Control Leveling Process

Monitor the leveling process and make adjustments as needed to maintain the desired flatness, thickness, and width of the metal.

- Inspect the metal before and after leveling to ensure the desired results are achieved.

- Troubleshoot and resolve any machine malfunctions or processing problems.

3. Maintain Equipment and Work Area

Maintain the stretcher-leveler equipment and work area to ensure safe and efficient operation.

- Clean and lubricate the machine regularly.

- Maintain a clean and organized work area, following established safety protocols.

- Report any maintenance or repair needs to the supervisor.

4. Comply with Safety Regulations

Comply with all applicable safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE) and follow established safety guidelines.

- Operate the equipment safely and in accordance with manufacturer’s instructions.

- Report any unsafe work conditions or practices.

Interview Tips

To help you ace your interview for a Stretcher-Leveler Operator position, consider the following tips:

1. Be well-prepared

Familiarize yourself with the job description and research the company. Understand the company’s values, mission, and industry.

- Review the key job responsibilities and prepare examples of your experience that demonstrate your skills and abilities.

- Research the specific stretcher-leveler equipment used in the industry and familiarize yourself with its operation.

2. Practice your answers

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice your answers out loud or with a friend or family member to improve your delivery.

3. Highlight your skills and experience

Emphasize your skills and experience that are relevant to the job, particularly your ability to operate stretcher-leveler equipment.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

- Provide examples of how you have successfully resolved problems or improved efficiency in previous roles.

- Be prepared to discuss your knowledge of safety regulations and procedures related to stretcher-leveler operation.

4. Ask insightful questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position.

- Prepare questions about the company’s culture, growth opportunities, and the specific responsibilities of the role.

- Avoid asking generic questions or questions that can be easily answered by researching the company website.

Next Step:

Now that you’re armed with the knowledge of Stretcher-Leveler Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Stretcher-Leveler Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini