Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stretching Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

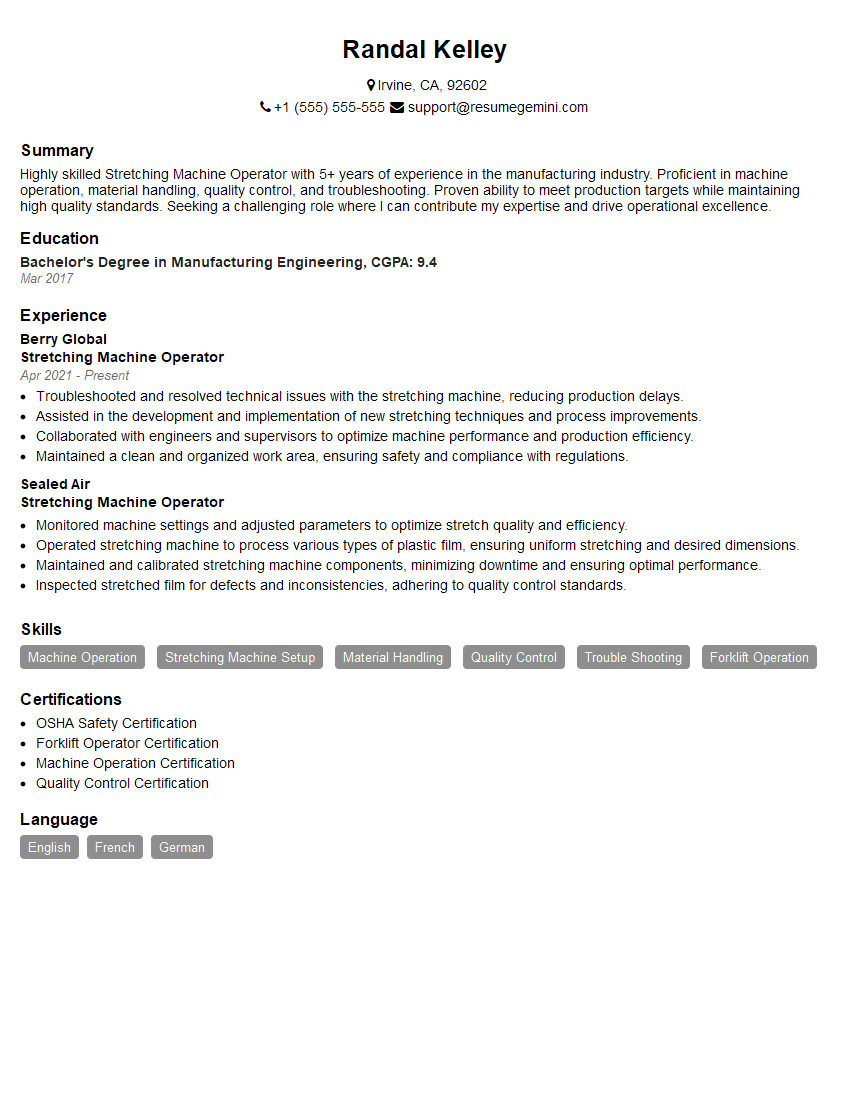

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stretching Machine Operator

1. Can you explain the different types of stretching machines and their uses?

- Hydraulic Stretching Machine: These are used for stretching materials such as metal, plastic, and rubber. They use hydraulic pressure to apply force to the material, which is then stretched to the desired length and width.

- Mechanical Stretching Machine: These machines use mechanical force to stretch materials. They have a series of rollers that grip the material and pull it through the machine, stretching it to the desired dimensions.

- Ultrasonic Stretching Machine: These machines use ultrasonic waves to stretch materials. The ultrasonic waves create vibrations that cause the material to stretch and relax, which results in a more uniform and consistent stretch.

2. What are the key factors to consider when setting up a stretching machine?

Factors to consider

- Material thickness: The thickness of the material will determine the amount of force required to stretch it and the speed at which it can be stretched.

- Material type: Different materials have different stretching properties, so it is important to select the right machine for the material being used.

- Desired stretch: The desired stretch will determine the amount of force and speed required to stretch the material.

- Machine capacity: The machine capacity will determine the maximum size and thickness of material that can be stretched.

Additional Factors

- Safety: It is important to ensure that the machine is properly set up and operated in a safe manner.

- Maintenance: The machine should be regularly maintained to ensure that it is operating properly and safely.

3. How do you troubleshoot common problems that occur with stretching machines?

- Material not stretching evenly: This can be caused by a number of factors, such as incorrect machine setup, improper material preparation, or worn or damaged machine parts.

- Material tearing: This can be caused by excessive force being applied to the material, or by using a machine that is not suited for the material being used.

- Machine overheating: This can be caused by a number of factors, such as excessive use, lack of lubrication, or a faulty motor.

4. What are the safety precautions that need to be followed when operating a stretching machine?

- Wear appropriate safety gear: This includes safety glasses, gloves, and earplugs.

- Keep the work area clean and clear: This will help to prevent accidents.

- Be aware of the machine’s controls: Make sure you know how to operate the machine safely before using it.

- Never put your hands or fingers near the moving parts of the machine: This could result in serious injury.

- Follow the manufacturer’s instructions for operating the machine: This will help to ensure that the machine is used safely and effectively.

5. What are the maintenance procedures that need to be performed on a stretching machine?

- Clean the machine regularly: This will help to prevent dirt and debris from building up and causing problems.

- Lubricate the machine according to the manufacturer’s instructions: This will help to keep the machine running smoothly and prevent wear and tear.

- Inspect the machine regularly for any signs of damage: If you find any damage, repair it immediately.

- Follow the manufacturer’s instructions for maintaining the machine: This will help to ensure that the machine is maintained properly and lasts for many years.

6. How do you ensure that the stretched materials meet the required quality standards?

- Follow the manufacturer’s instructions for operating the machine: This will help to ensure that the machine is used properly and that the materials are stretched to the correct dimensions.

- Inspect the materials after they have been stretched: Look for any defects, such as tears, wrinkles, or uneven stretching.

- Use a quality control system to ensure that the materials meet the required standards: This could involve using a measuring device to check the dimensions of the materials or using a visual inspection to check for defects.

7. How do you stay updated with the latest advancements in stretching technology?

- Read trade publications: This is a great way to learn about new products and technologies.

- Attend trade shows: This is a good opportunity to see the latest machines and talk to manufacturers.

- Network with other professionals: This is a great way to learn about new techniques and best practices.

8. What are your strengths and weaknesses as a Stretching Machine Operator?

- I have a strong understanding of the principles of stretching and how to apply them to different materials.

- I am experienced in operating a variety of stretching machines and can quickly adjust them to meet the requirements of different materials.

- I am a safety-conscious worker and always follow the manufacturer’s instructions for operating the machines.

- I am a team player and am always willing to help out my colleagues.

- I am still relatively new to the industry and do not have as much experience as some of the other operators.

- I am not familiar with all of the latest advancements in stretching technology.

Strengths

Weaknesses

9. Why are you interested in this position?

- I am interested in this position because it would allow me to use my skills and experience to help your company produce high-quality stretched materials.

- I am confident that I can be a valuable asset to your team and help you achieve your production goals.

- I am eager to learn more about the latest advancements in stretching technology and I am confident that I can quickly become a proficient operator of your machines.

10. What are your salary expectations for this position?

- My salary expectations for this position are in line with the industry average for a Stretching Machine Operator with my experience and skills.

- I am open to negotiating a salary that is fair and commensurate with my value to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stretching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stretching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stretching Machine Operators play a crucial role in textile manufacturing by operating and maintaining stretching machines responsible for stretching and dyeing fabrics to impart desired properties. Their responsibilities encompass a wide range of tasks, including:

1. Machine Operation and Maintenance

– Operating stretching machines to stretch fabrics according to specified widths and lengths. – Monitoring machine performance, adjusting tension and speed settings as needed to maintain optimal operation. – Performing routine maintenance, including lubrication, cleaning, and minor repairs to ensure machine efficiency.

2. Fabric Handling and Inspection

– Loading and unloading fabrics onto stretching machines, ensuring proper alignment and tension. – Inspecting fabrics before and after stretching to identify defects or imperfections. – Maintaining proper inventory and records of fabrics processed.

3. Process Control and Quality Assurance

– Following technical specifications and adhering to established process parameters to achieve desired fabric properties. – Monitoring and controlling machine settings, temperature, and tension to ensure consistent stretching results. – Conducting quality checks to ensure fabrics meet required standards and specifications.

4. Health, Safety, and Environment

– Complying with all safety regulations and procedures to operate machines safely and efficiently. – Maintaining a clean and organized work area, adhering to environmental regulations and waste management practices. – Reporting any accidents, incidents, or potential hazards to supervisors or management promptly.

Interview Tips

Preparing thoroughly for a Stretching Machine Operator interview can significantly increase your chances of success. Here are some valuable tips and tricks to help you ace the interview:

1. Research the Company and Position

– Familiarize yourself with the company’s history, products, and industry standing. – Understand the specific requirements and responsibilities of the Stretching Machine Operator role. – Research the company’s culture and values to demonstrate alignment with their work environment.

2. Highlight Relevant Experience and Skills

– Emphasize your previous experience operating stretching machines or related equipment. – Showcase your understanding of fabric types, stretching techniques, and quality control processes. – Highlight your proficiency in maintaining and troubleshooting machinery to ensure smooth operations.

3. Prepare for Common Interview Questions

– Practice answering common interview questions tailored to the Stretching Machine Operator role, such as:

- Tell me about your experience operating stretching machines.

- How do you ensure consistent stretching results and maintain fabric quality?

- Describe a time you solved a problem or improved a process related to stretching operations.

4. Ask Thoughtful Questions

– Prepare insightful questions to ask the interviewer, demonstrating your interest and engagement. Examples include:

- What are the company’s growth plans and how does this role contribute to them?

- Can you provide more details about the training and development opportunities within the organization?

- How does the company ensure compliance with safety and environmental regulations in its manufacturing processes?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stretching Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!