Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Strike Off Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

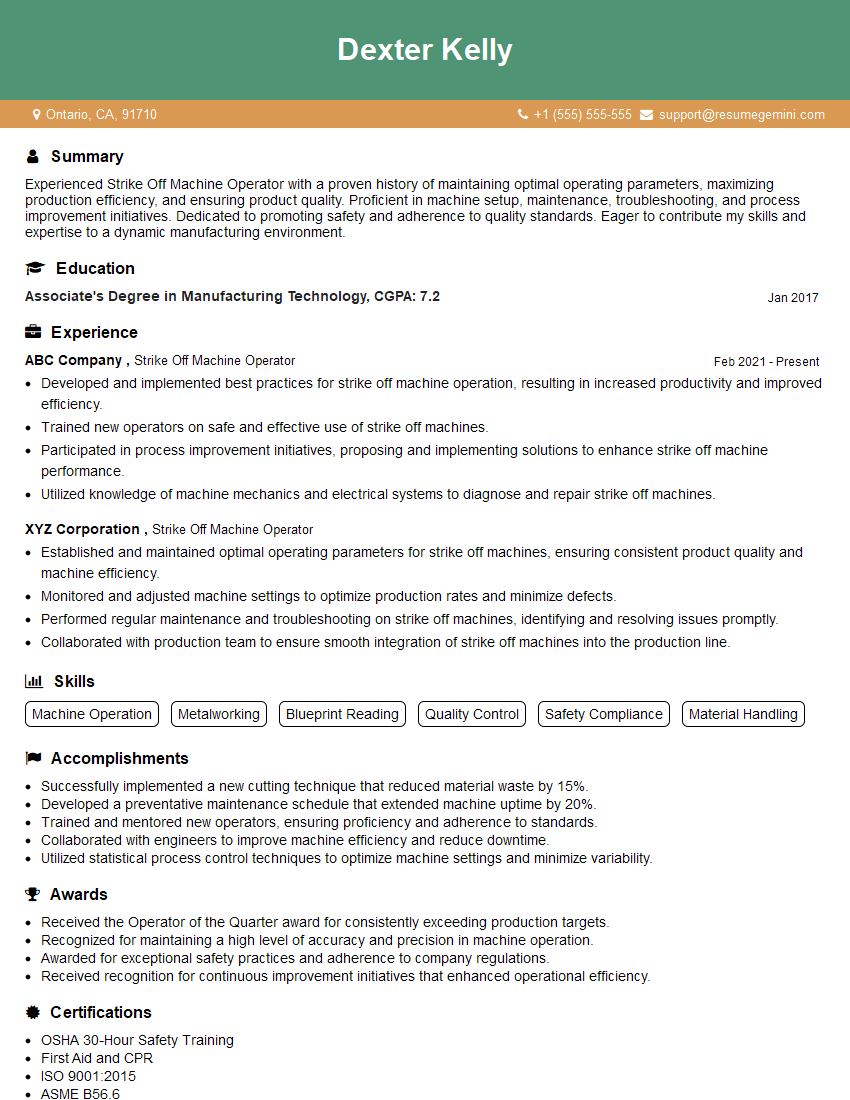

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Strike Off Machine Operator

1. Explain the process of operating a strike-off machine?

To operate a strike-off machine, I would follow these steps:

- Load the material onto the machine’s table.

- Adjust the machine’s settings to match the material’s thickness and desired finish.

- Start the machine and guide the material through the cutting head.

- Monitor the machine’s progress and make adjustments as needed.

- Unload the finished material from the machine.

2. What are the different types of strike-off machines?

There are three main types of strike-off machines:

- Manual strike-off machines are operated by hand and require the operator to manually feed the material through the cutting head.

- Semi-automatic strike-off machines are operated by a foot pedal or switch, and the material is automatically fed through the cutting head.

- Automatic strike-off machines are fully automated and do not require any operator intervention.

3. What are the safety precautions that should be taken when operating a strike-off machine?

When operating a strike-off machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep hands and other body parts away from the cutting head.

- Do not operate the machine if it is not properly grounded.

- Be aware of the machine’s surroundings and keep others at a safe distance.

- Follow all manufacturer’s instructions for safe operation.

4. What are the common problems that can occur when operating a strike-off machine?

Some common problems that can occur when operating a strike-off machine include:

- Material jams

- Cuts that are not straight or clean

- Machine vibrations

- Overheating

- Electrical problems

5. How do you troubleshoot and resolve problems with a strike-off machine?

To troubleshoot and resolve problems with a strike-off machine, I would follow these steps:

- Identify the problem and gather information about it.

- Refer to the machine’s manual or consult with a qualified technician.

- Take corrective action to resolve the problem.

- Test the machine to ensure that the problem has been resolved.

6. What are the different types of materials that can be processed on a strike-off machine?

A strike-off machine can process a variety of materials, including:

- Wood

- Plastic

- Metal

- Rubber

- Foam

7. What are the different finishes that can be achieved with a strike-off machine?

A strike-off machine can achieve a variety of finishes, including:

- Smooth and flat

- Textured

- Beveled

- Rounded

8. What are the key factors that affect the quality of the finished product?

The key factors that affect the quality of the finished product include:

- The type of material being processed

- The settings of the strike-off machine

- The skill of the operator

- The maintenance of the machine

9. What are the preventive maintenance tasks that should be performed on a strike-off machine?

To ensure the proper functioning of a strike-off machine, preventive maintenance tasks should be performed on a regular basis. These tasks include:

- Cleaning the machine

- Lubricating the machine’s moving parts

- Checking the machine’s electrical connections

- Inspecting the machine’s cutting head

10. What are your strengths and weaknesses as a strike-off machine operator?

My strengths as a strike-off machine operator include:

- Attention to detail

- Strong mechanical aptitude

- Ability to work independently and as part of a team

- Experience with a variety of materials and finishes

My areas for improvement include:

- Experience with automated strike-off machines

- Knowledge of CNC programming

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Strike Off Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Strike Off Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Strike Off Machine Operator plays a crucial role in the manufacturing process, ensuring the precision and quality of the finished products. Here are the key job responsibilities:

1. Machine Operation

The primary responsibility involves operating and controlling the Strike Off Machine to manufacture high-quality products according to specifications.

- Set up and operate the machine efficiently to achieve the desired product dimensions and tolerances.

- Monitor machine operations and make necessary adjustments to optimize performance and minimize defects.

2. Quality Control

Ensuring the quality of finished products is paramount. The operator must:

- Inspect and measure products against specifications using precision tools to ensure dimensional accuracy.

- Identify and rectify any defects in the manufacturing process to maintain product quality.

3. Maintenance and Troubleshooting

Regular maintenance is essential for smooth machine operation. The operator is responsible for:

- Performing routine maintenance tasks, such as cleaning, lubrication, and minor repairs.

- Troubleshooting any mechanical or electrical issues that arise during machine operation.

4. Process Improvement

The operator should actively seek ways to improve the manufacturing process. This may include:

- Suggesting modifications to the machine or process to enhance efficiency or product quality.

- Cooperating with the engineering team to implement process improvements.

Interview Tips

To ace the interview for a Strike Off Machine Operator position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company’s background, industry, and the specific role you’re applying for. This will demonstrate your interest and understanding of the organization and the position.

- Visit the company website and social media pages.

- Read news articles and industry reports about the company.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and any experience operating Strike Off Machines or similar equipment.

- Quantify your accomplishments using specific metrics, such as the number of units produced or the reduction in defect rates.

- Provide examples of how you have solved problems or made improvements in previous roles.

3. Demonstrate Attention to Detail

Strike Off Machine Operators must possess exceptional attention to detail. Highlight your ability to:

- Follow precise instructions and specifications meticulously.

- Spot and rectify errors in the manufacturing process.

4. Emphasize Teamwork and Problem-Solving

Collaboration and problem-solving are crucial in manufacturing environments. Showcase your ability to:

- Work effectively as part of a team.

- Identify and resolve issues proactively.

5. Prepare for Technical Questions

Be prepared to answer technical questions related to Strike Off Machine operation and maintenance. Review basic machine principles and troubleshooting techniques.

- Practice answering questions about the types of Strike Off Machines, their components, and common problems.

- Demonstrate your understanding of quality control procedures and inspection techniques.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Strike Off Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!