Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Strip Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

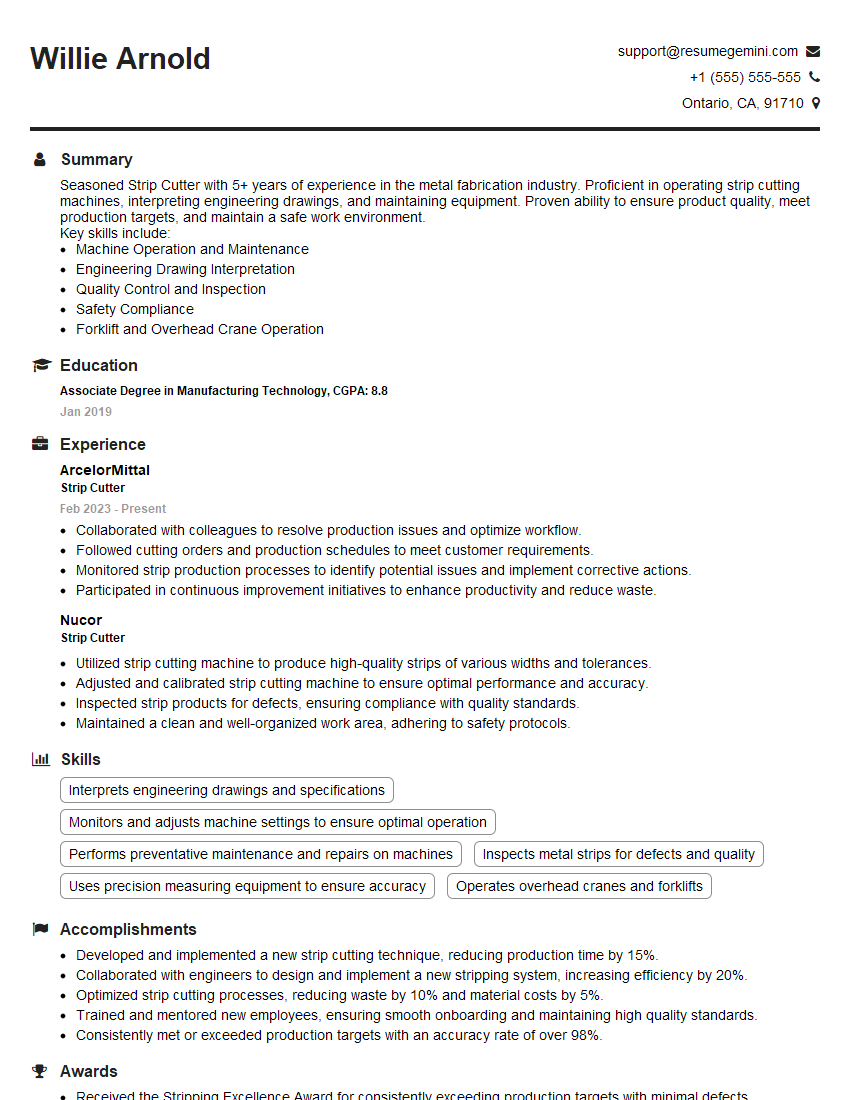

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Strip Cutter

1. How do you ensure the strip cutters are cutting to the correct length and width?

- Use precision measurement tools, such as micrometers and calipers, to verify the dimensions of the cut strips.

- Regularly calibrate the strip cutters to maintain accuracy.

- Inspect the cut strips visually and use templates to ensure they meet the specified tolerances.

2. What steps do you take to maintain and troubleshoot the strip cutters?

Regular Maintenance

- Lubricate moving parts to prevent wear and tear.

- Clean the cutters and remove any debris or buildup.

- Check the blades for sharpness and replace them when necessary.

Troubleshooting

- Identify the issue by observing symptoms and error messages.

- Consult technical manuals and diagrams to locate the source of the problem.

- Perform necessary repairs or adjustments to restore functionality.

3. How do you handle situations where the strip cutter malfunctions or produces defective strips?

- Stop the cutting process immediately to prevent further damage.

- Identify the cause of the malfunction or defect.

- Take corrective action, such as repairing or replacing faulty components.

- Document the incident and report it to the supervisor or maintenance team.

4. What safety precautions do you follow when operating strip cutters?

- Wear appropriate safety gear, such as gloves, eye protection, and earplugs.

- Keep hands and loose clothing away from moving parts.

- Ensure the work area is well-lit and free from hazards.

- Follow established safety protocols and lockout procedures.

5. How do you optimize the efficiency of the strip cutting process?

- Regularly service and maintain the strip cutters to minimize downtime.

- Use sharp blades to reduce cutting force and improve strip quality.

- Optimize material feed rates to maximize throughput while maintaining accuracy.

- Implement automated processes, such as automatic feeding and stacking, to increase efficiency.

6. What types of materials are you experienced in cutting with strip cutters?

- Metals (e.g., aluminum, steel, copper)

- Plastics (e.g., PVC, polycarbonate, acrylic)

- Composites (e.g., fiberglass, carbon fiber)

- Paper and cardboard

- Fabrics (e.g., leather, canvas, vinyl)

7. How do you handle variations in material thickness and hardness when cutting strips?

- Adjust the cutting force and blade settings to accommodate different materials.

- Use multiple passes for thicker materials to achieve the desired cut quality.

- Experiment with different blade types and coatings to optimize performance for specific materials.

8. What is your approach to quality control for cut strips?

- Establish clear quality standards and tolerances.

- Perform regular inspections throughout the cutting process.

- Use measurement tools and gauges to verify strip dimensions and surface finish.

- Document inspection results and take corrective actions as needed.

9. How do you manage waste and scrap material generated by the strip cutting process?

- Implement waste reduction strategies, such as optimizing material usage and minimizing trim waste.

- Segregate and recycle scrap material to reduce environmental impact.

- Explore opportunities for repurposing or reusing scrap material in other applications.

10. What are some of the challenges you have faced in your previous role as a Strip Cutter and how did you overcome them?

- Challenge: Maintaining accuracy in cutting strips to tight tolerances.

- Solution: Implemented regular calibration procedures and used precision measurement tools to ensure consistent results.

- Challenge: Troubleshooting electrical malfunctions in the strip cutter.

- Solution: Studied electrical diagrams, consulted technical manuals, and received training from a qualified electrician.

- Challenge: Optimizing the cutting process for efficiency.

- Solution: Conducted time studies, analyzed process bottlenecks, and implemented automation to increase throughput.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Strip Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Strip Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Strip Cutter is responsible for operating a machine that slices wide rolls of material into narrow strips. They often work in manufacturing environments like paper mills, steel fabrication shops, or textile factories.

1. Operating Machinery

The primary responsibility of a Strip Cutter is to set up and operate the cutting machine. This involves loading the material into the machine, adjusting the cutting blades, and monitoring the cutting process to ensure that the strips are cut to the correct size and quality.

- Loading and unloading materials

- Adjusting and maintaining cutting blades

- Setting up and operating cutting machine

2. Quality Control

Strip Cutters are responsible for ensuring that the cut strips meet the required specifications. They inspect the strips for defects, such as tears, wrinkles, or uneven edges, and make adjustments to the cutting process as needed.

- Inspecting cut strips for quality

- Identifying and correcting defects

- Maintaining quality standards

3. Material Handling

Strip Cutters are often responsible for handling and transporting the materials before and after the cutting process. This may involve loading and unloading rolls of material, moving cut strips to storage areas, or disposing of scrap material.

- Handling and transporting materials

- Loading and unloading rolls of material

- Moving cut strips to storage areas

4. Safety

Strip Cutters must follow all safety procedures and wear appropriate safety gear to prevent accidents. This includes wearing gloves, safety glasses, and earplugs, and being aware of potential hazards in the work area.

- Following safety procedures

- Wearing appropriate safety gear

- Identifying and avoiding potential hazards

Interview Tips

Preparing for an interview for a Strip Cutter position requires research, practice, and a positive attitude. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take the time to learn about the company, its products or services, and the specific Strip Cutter position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website

- Read industry news and articles

- Network with people in the industry

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experience.

- Use the STAR method to answer questions

- Practice answering common interview questions

- Get feedback from friends or family

3. Highlight Your Skills and Experience

During the interview, make sure to highlight your skills and experience that are relevant to the Strip Cutter position. Emphasize your ability to operate machinery, maintain quality standards, and work safely in a manufacturing environment.

- Tailor your resume and cover letter to the job description

- Highlight your relevant skills and experience

- Provide specific examples of your accomplishments

4. Be Professional and Enthusiastic

First impressions matter, so it is important to dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet, and maintain a positive attitude throughout the interview. Show enthusiasm for the position and the company, and be prepared to ask thoughtful questions.

- Dress professionally

- Arrive on time for your interview

- Be polite and respectful

- Ask thoughtful questions

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Strip Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!