Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Strip Cutting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

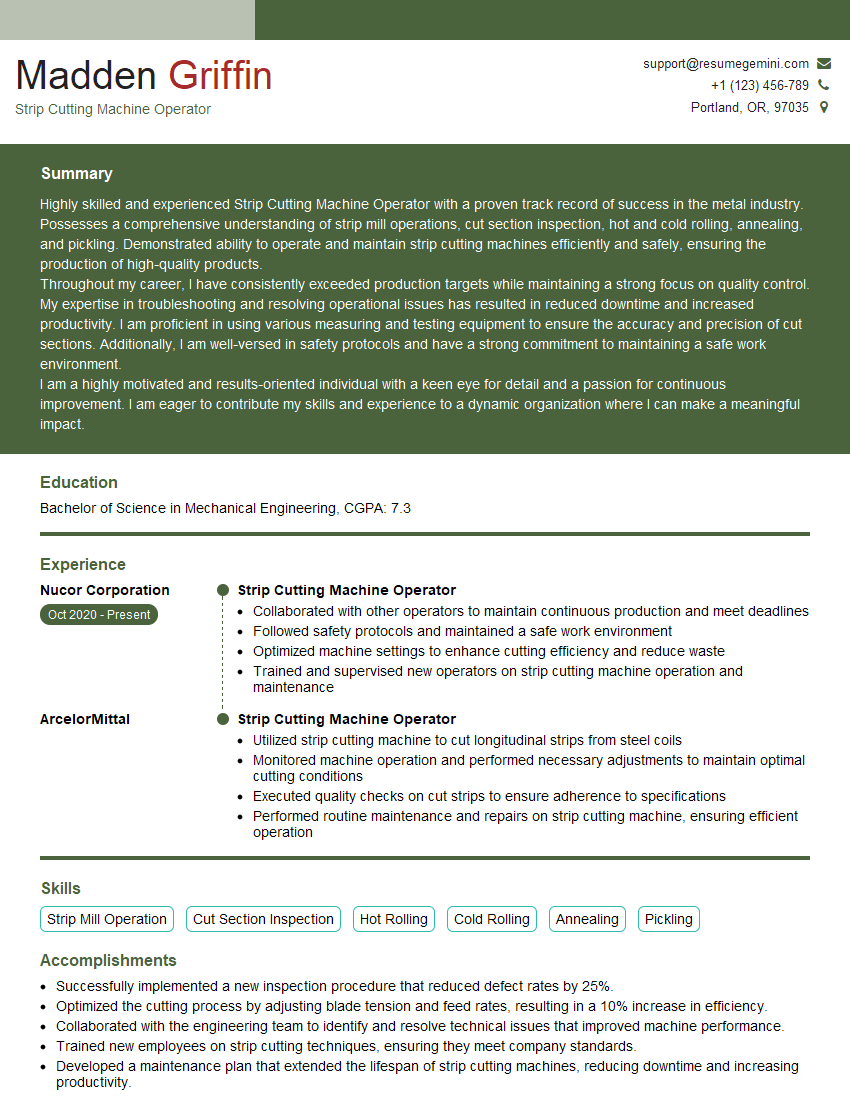

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Strip Cutting Machine Operator

1. What are the important safety precautions you follow while operating a strip cutting machine?

Here are some important safety precautions I follow while operating a strip cutting machine:

- Wear appropriate personal protective equipment (PPE).

- Inspect the machine before each use.

- Ensure that the machine is properly grounded.

- Keep the work area clean and free of debris.

- Never operate the machine under the influence of drugs or alcohol.

- Follow all manufacturer’s instructions.

2. How do you adjust the cutting blade of a strip cutting machine?

Blade Height Adjustment

- Loosen the blade height adjustment screws.

- Raise or lower the blade to the desired height.

- Tighten the blade height adjustment screws.

Blade Angle Adjustment

- Loosen the blade angle adjustment screws.

- Adjust the blade to the desired angle.

- Tighten the blade angle adjustment screws.

3. How do you troubleshoot a strip cutting machine that is not cutting straight?

There are several potential causes for a strip cutting machine that is not cutting straight. Some common troubleshooting steps include:

- Check the blade for sharpness and alignment.

- Check the feed rollers for wear or damage.

- Check the machine’s bearings for wear or damage.

- Check the machine’s frame for alignment.

- Check the hydraulic system for leaks or other problems.

4. How do you maintain a strip cutting machine?

Regular maintenance is essential to keep a strip cutting machine operating properly. Some common maintenance tasks include:

- Cleaning the machine regularly.

- Lubricating the machine’s moving parts.

- Inspecting the machine’s electrical system.

- Inspecting the machine’s hydraulic system.

- Performing regular blade changes.

5. What are the different types of strip cutting machines?

There are several different types of strip cutting machines, each with its own advantages and disadvantages. Some common types include:

- Rotary strip cutting machines.

- Guillotine strip cutting machines.

- Slitter strip cutting machines.

- Shear strip cutting machines.

- Laser strip cutting machines.

6. How do you choose the right strip cutting machine for a particular job?

When choosing a strip cutting machine for a particular job, it is important to consider several factors, including:

- The type of material being cut.

- The thickness of the material being cut.

- The width of the strips being cut.

- The accuracy required.

- The production volume.

7. What are the different types of blades used in strip cutting machines?

There are several different types of blades used in strip cutting machines, each with its own advantages and disadvantages. Some common types include:

- High-carbon steel blades.

- Alloy steel blades.

- Carbide blades.

- Ceramic blades.

- Diamond blades.

8. How do you set up a strip cutting machine?

To set up a strip cutting machine, you will need to follow these steps:

- Place the machine on a stable surface.

- Connect the machine to a power source.

- Install the blade.

- Adjust the machine’s settings.

- Load the material to be cut.

9. What are the common problems that can occur when operating a strip cutting machine?

Some common problems that can occur when operating a strip cutting machine include:

- The machine not cutting straight.

- The machine not cutting to the desired width.

- The machine not cutting through the material.

- The machine overheating.

- The machine making excessive noise.

10. How do you troubleshoot a strip cutting machine that is not cutting?

If a strip cutting machine is not cutting, there are several potential causes. Some common troubleshooting steps include:

- Checking the power supply.

- Checking the blade.

- Checking the feed rollers.

- Checking the hydraulic system.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Strip Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Strip Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Strip Cutting Machine Operators play a crucial role in the production process, ensuring the efficient and precise cutting of materials into strips. Their responsibilities encompass:

1. Machine Operation

Operating strip cutting machines to cut materials such as paper, plastic, metal, or rubber into strips of specified widths and lengths.

- Setting up and adjusting the machine according to material and cutting requirements.

- Monitoring the cutting process and making necessary adjustments to maintain quality and efficiency.

2. Quality Control

Inspecting cut strips to ensure they meet specifications for dimensions, tolerances, and surface finish.

- Using measuring tools and gauges to verify accuracy.

- Identifying and correcting any defects or deviations promptly.

3. Material Handling

Loading and unloading materials onto the cutting machine.

- Safely handling and storing raw materials and finished products.

- Maintaining a clean and organized work area.

4. Machine Maintenance

Performing basic maintenance tasks on the cutting machine.

- Cleaning and lubricating machine parts.

- Reporting any malfunctions or maintenance needs promptly.

Interview Tips

To ace the interview for a Strip Cutting Machine Operator position, candidates should prepare thoroughly and highlight their skills and experience. Here are some key tips and hacks:

1. Research the Company and Position

Research the company’s website, products, and industry to demonstrate your interest and understanding of their operations. Review the job description carefully to identify the specific requirements and responsibilities.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivation. Consider the STAR method (Situation, Task, Action, Result):

- Situation: Describe a specific situation or task related to the job.

- Task: Explain the task you were responsible for completing.

- Action: Describe the specific actions you took to complete the task.

- Result: State the outcome or result of your actions.

3. Highlight Relevant Skills and Experience

Emphasize your previous experience operating strip cutting machines and your ability to meet production targets. Showcase your knowledge of machine maintenance and troubleshooting techniques.

4. Demonstrate Attention to Detail and Safety

Consistently ensuring that cut strips meet specifications is crucial. Emphasize your ability to pay attention to detail and your commitment to maintaining a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Strip Cutting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!